Ceramic Gauge for Inspection & Metrology — Sets and Singles

ADCERAX is a factory-direct supplier of ceramic gauge made from zirconia (ZrO₂)and alumina. Custom sets and individual replacements are available to match your size list, grade/class, marking, and packaging requirements.

They help reduce rust-related surface changes, magnetic attraction, inconsistent contact behavior, and handling chips in shop-floor checks, inspection verification, comparators, height gauge referencing, and fixture setup.

Tell us your application and grade—get a practical set/replacement recommendation and a fast quote.

What is Ceramic Gauge ?

Ceramic Gauge Definition

Ceramic gauge are precision-lapped length standards manufactured to defined grade/class tolerances and used as reference artifacts for dimensional metrology. They are assembled as sets or supplied as individual blocks to build known lengths for instrument verification, comparator work, and fixture setup, providing traceable reference points within a measurement system.

Why Upgrade to Our Ceramic Gauges from Steel?

Traditional steel gauges are prone to wear, corrosion, and dimensional changes due to temperature fluctuations, leading to frequent recalibration and potential inaccuracies. Our Ceramic Gauges solve these critical issues. Engineered from advanced ceramics, they provide a leap forward in metrology performance, offering:

🛡️ Massively Extended Lifespan

Up to 10 times the wear resistance of steel under repeated contact cycles.

🧩Reduced Operational Costs

Less frequent calibration and replacement means significant long-term savings.

📏 Consistent Measurement Accuracy

Minimal thermal expansion ensures reliability across varying temperatures.

🧲 Interference-Free Measurement

Non-magnetic and non-conductive properties are ideal for sensitive environments.

Ceramic Gauge Block Properties

Ceramic gauge blocks are hard, wear-resistant, and non-magnetic, with stable working-face geometry and repeatable contact behaviour in inspection routines. They are corrosion-resistant and maintaina consistent surface condition under normal gage-room handling and storage.

Alumina Gauge

Alumina (Al₂O₃) gauge offer high hardness and wear resistance for stable working faces in routine inspection workflows, with cost-efficient performance for daily verification.

| Property | Unit | 96% Al₂O₃ | 99% Al₂O₃ | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

|---|---|---|---|---|---|---|---|---|---|

| Alumina content | % | 96 | 99 | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.75 | 3.88 | 3.89 | 3.91 | 3.92 | 3.93 | 3.95 | 3.98 |

| Flexural strength | MPa | 330 | 360 | 379 | 312 | 313 | 314 | 315 | 320 |

| Hardness | GPa | 11.5 | 13.5 | 14.1 | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 20–25 | 30–35 | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance (ΔT) | °C | 150 | 200 | — | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1600 | ≤1700 | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Dielectric strength | kV/mm | 8–10 | 10–12 | 11–13 | 12–14 | 12–15 | 13–16 | 14–17 | 15–18 |

| Volume resistivity (25°C) | Ω·cm | ≥1×10¹³ | ≥1×10¹⁴ | ≥3×10¹⁴ | ≥5×10¹⁴ | ≥1×10¹⁵ | ≥3×10¹⁵ | ≥5×10¹⁵ | ≥1×10¹⁶ |

- This chart displays the typical properties of alumina (Al2O3) gauge used in our standard products. Please note: Customized parts may have adjusted characteristics depending on production methods, with specific parameters determined by the stabilizer type and formula chosen for your application.

Zirconia Ceramic Gauge

Zirconia (ZrO₂) gauge offer higher toughness with strong wear stability to reduce edge chipping during frequent handling, while remaining non-magnetic for consistent use around magnetized tools.

| Property | Unit | Typical Range | Why Buyers Specify It |

|---|---|---|---|

| Density | g/cm³ | 4.00 – 4.30 | Indicates densification and batch consistency |

| Flexural Strength | MPa | 700 – 1,200 | Impacts handling breakage risk and safety margin |

| Fracture Toughness | MPa·√m | 6 – 10 | Key ZTA advantage for edge-chipping and crack resistance |

| Hardness (Vickers) | GPa | 14 – 17 | Affects wear/scratch resistance and machinability |

| Thermal Conductivity | W/m·K | 18 – 30 | Drives heat spreading performance (typically below AlN) |

| CTE (20–300°C) | ×10⁻⁶ /K | 8.0 – 9.5 | Influences thermal-cycling stress and material matching |

| Dielectric Strength | kV/mm | 10 – 15 | Determines insulation margin (depends on thickness/surface) |

| Volume Resistivity (25°C) | Ω·cm | 10¹² – 10¹⁴ | Indicates insulation stability and leakage risk |

- Values are typical ranges; they vary with ZrO₂ content, firing profile, and final density.

MSZ Ceramic Gauge Block

MSZ gauge block: A tougher, stronger zirconia option that adds extra durability margin for repeated contact cycles and harsher handling, supporting long-term repeatability in busy QC routines.

| Property | Specification |

|---|---|

| Material Type | Magnesia Stabilized Zirconia (MSZ) |

| Density | > 5.80 g/cm³ |

| Vickers Hardness (HV10) | > 1300 HV |

| Bending Strength | > 800 MPa |

| Fracture Toughness (K₁c) | > 6.0 MPa·m¹ᐟ² |

| Thermal Conductivity | 2.5 W/m·K @ 20 °C |

| Thermal Expansion Coefficient | 10.3 ×10⁻⁶ /K @ 25–500 °C |

| Maximum Operating Temperature | 1000 °C continuous |

| Surface Finish (Ra) | < 0.05 µm (working faces) |

| Magnetic Permeability | ≈ 0 (non-magnetic) |

| Electrical Resistivity | > 10¹⁴ Ω·cm |

- This chart displays the typical properties of the MSZ gauge used in our standard products. Please note that customized parts may have adjusted characteristics, depending on the production method, with specific parameters determined by the stabiliser type and formula chosen for your application.

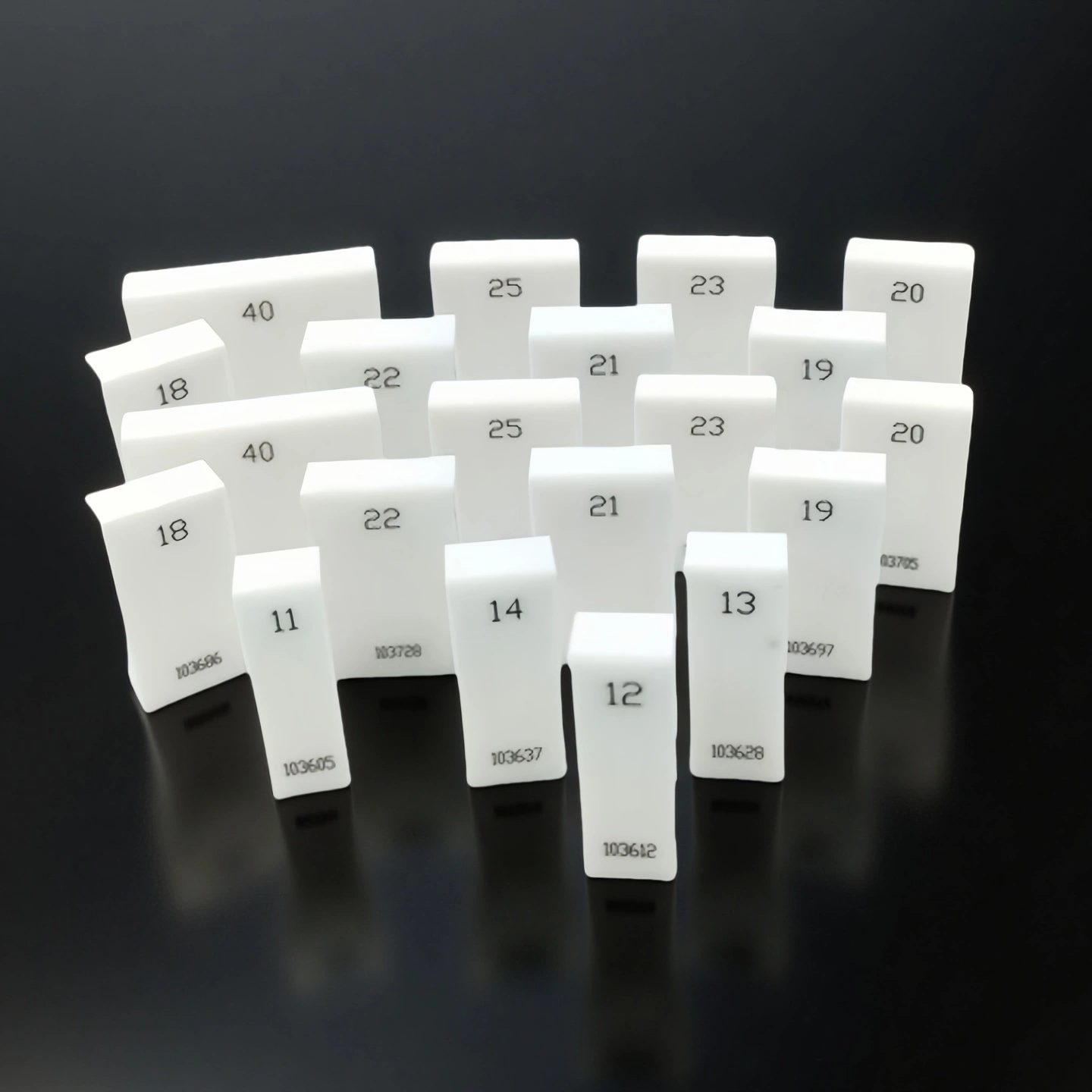

Ceramic Gauge Products

Explore ceramic gauge products for dimensional inspection and metrology—covering gauge blocks and related gauge components across common ceramic systems, with options for standard sets, individual replacements, and build-to-print customization.

Alumina Ceramic Gauge

Alumina ceramic gauge parts use Al₂O₃ to deliver high hardness, strong wear resistance, and stable geometry for routine inspection and shop-floor checks.

Zirconia Ceramic Gauge

Zirconia ceramic gauge parts use ZrO₂ to provide higher toughness and better edge damage resistance, helping reduce chipping during frequent handling and contact.

MSZ Ceramic Gauge

MSZ ceramic gauge block uses MSZ zirconia to combine toughness with wear stability, supporting reliable performance under repeated touch cycles and tougher handling.

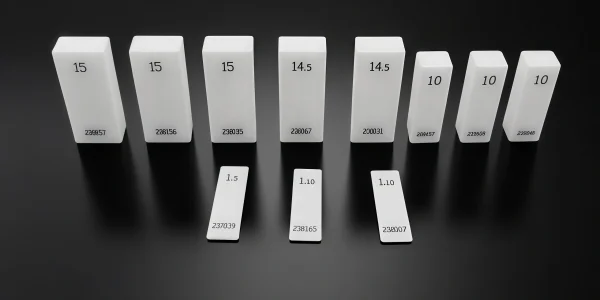

ceramic gauge block

Ceramic gauge blocks provide stable reference lengths for daily verification, with corrosion-resistant handling and consistent working faces for repeatable contact routines.

ceramic pin gauge

Ceramic pin gauges support precise small-hole and slot checks with strong wear resistance, helping maintain size integrity during frequent insert-and-check routines.

ceramic plug gauge

ACeramic plug gauges keep bore checks reliable in abrasive or wet environments, resisting wear and corrosion that can shift go/no-go results over repeated cycles.

ceramic ring gauge

Ceramic ring gauges deliver stable master references for external diameter checks, with low maintenance handling that reduces corrosion-driven variation in gauging rooms.

Ceramic Balls Gauge

Ceramic ball gauges maintain smooth contact for spherical reference checks, offering wear-stable surfaces that help keep repeatability in high-touch inspection routines.

Missing Ceramic Gauge Blocks? Replace Singles Without Rebuying a Full Set

Quote individual ceramic gauge blocks with matching grade/class and ID format, using your size list to restore full coverage without rebuying a complete set.

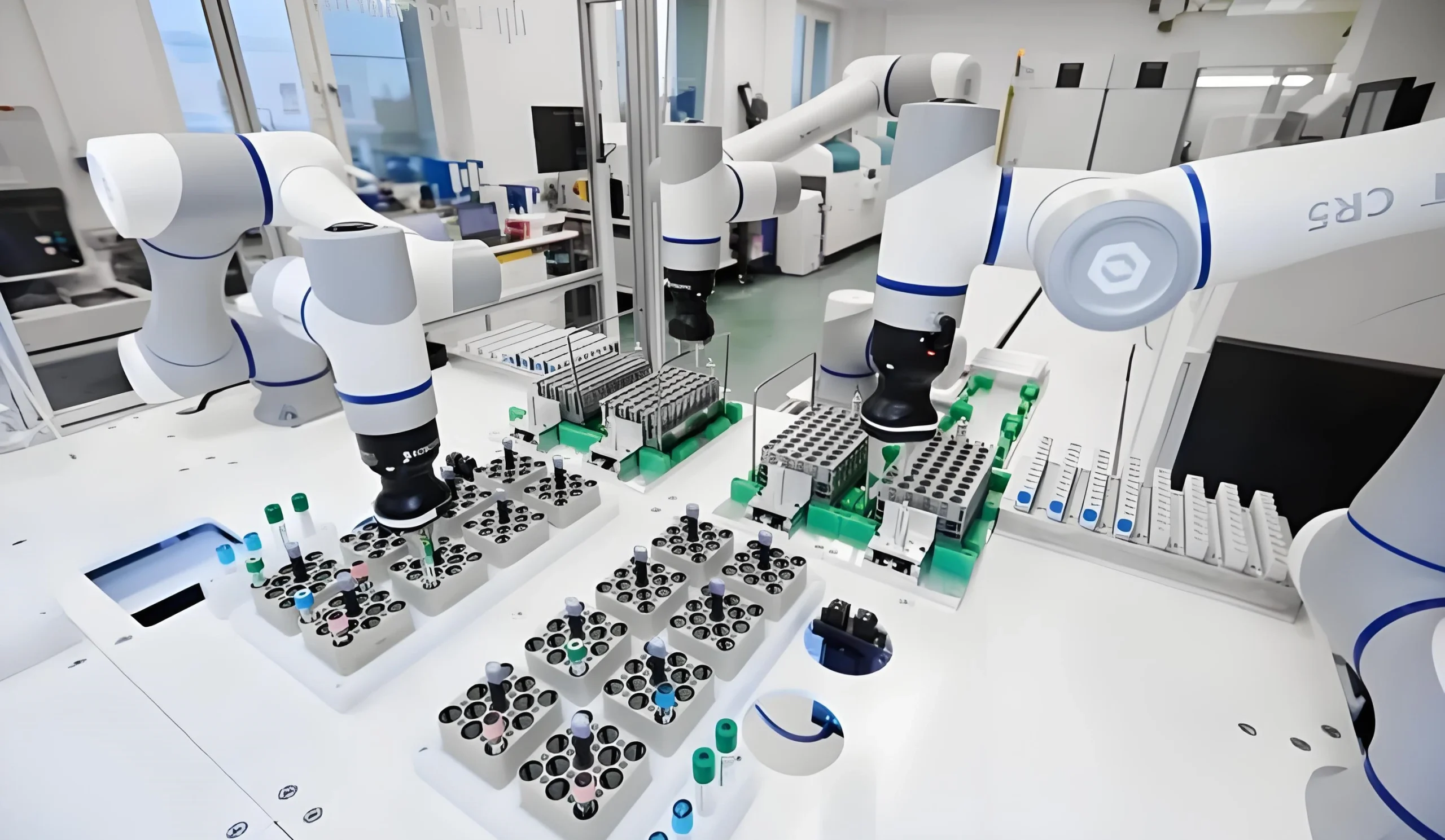

Applications of Precision Ceramic Gauges

Ceramic gauges serve as dimensional references for verification, setup, and go/no-go decisions in inspection and metrology workflows. They support repeatable instrument checks, comparator routines, and fixture alignment where reference integrity and documentation matter.

Precision Machining & Toolrooms

Used to verify micrometers, calipers, and height gauges, and to build known lengths for setup and alignment work. Common in first-article inspection, in-process checks, and gage room routines where repeatable reference handling reduces measurement disputes.

🧩ADCERAX ceramic gauges bolck help reduce measurement disputes and rework by keeping reference standards consistent across operators, shifts, and gage-room routines, and they prevent downtime caused by incomplete kits by supporting single-piece replacement with consistent ID and set composition.

Automotive & General Manufacturing QC

Used to standardize daily verification routines across shifts and cells, especially where multiple operators share measuring tools. Helps maintain consistent pass/fail decisions in inspection-room workflows and supports traceability practices in quality systems.

🧩ADCERAX ceramic pin gauges help stabilize pass/fail decisions across multiple lines by standardizing daily verification references and documentation expectations, making checks easier to repeat and audit when measuring tools are shared and schedules are tight.

Fixture, Tooling, and Assembly Setup

Used to set spacing, parallelism, and reference positions in fixtures and tooling, and to validate setup repeatability before production runs. Practical for alignment checks, gauge station setup, and controlled build-to-print assembly referencing.

🧩ADCERAX ceramic gauges help shorten setup time by providing predictable reference lengths for spacing and alignment, reducing trial-and-error adjustments and minimizing setup-to-setup variation in fixture builds and tooling changes.

Mechanical R&D and Engineering Labs

Used for controlled verification routines during prototype evaluation, tolerance studies, and measurement method validation. Supports repeatable setup blocks for test rigs, dimensional checkpoints, and comparison measurements across iterations.

🧩ADCERAX ceramic gauge block set help keep prototype measurement routines repeatable by providing stable reference artifacts for method validation and tolerance studies, while allowing practical customization of set coverage as projects evolve.

Custom Ceramic Gauge — Options & Process

ADCERAX custom ceramic gauges are built to match your size, grade/class, marking/ID format, certificate option, and case layout for sets or single replacements. Typical customization lead time is 2–9 weeks, depending on specification complexity and set composition.

Customization Options

Build sets or singles from your exact metric/inch size list. Support missing-block replacement and custom set composition.

Choose the grade/class that fits shop-floor checks or inspection routines. Tolerance and verification level align to your measurement workflow.

Define length marking, serial/ID rules, and labeling position. Helps prevent mix-ups and keeps replacements consistent across kits.

Specify surface condition for stable contact behavior and repeatable checks. Support flatness/parallelism focus for your grade/class needs.

Customization Process

Share system (metric/inch), set or singles, grade/class, size list, quantity, and ship-to country for quoting.

We confirm grade/class, marking/ID format, certificate option, case layout, and replacement matching rules.

We manufacture to the confirmed spec and complete dimensional inspection with documented acceptance criteria.

Blocks are packed in labeled storage, protected for transit, and shipped with export-ready documentation.

ADCERAX: A Trusted Ceramic Gauge Manufacturer

ADCERAX is a specialized ceramic gauge manufacturer, supplying ceramic gauge blocks and related gauges in standard sets and custom configurations with controlled material quality, grade/class selection, and stable dimensional consistency. Our engineering support, sampling service, and export experience help simplify global sourcing and keep verification programs on schedule.

Competitive pricing with strict quality control from raw material sourcing to final delivery

Professional team providing comprehensive technical support and collaborative design

Small batch orders to large-scale production with complex geometries and tight tolerances

24-hour response and 24-hour dispatch for standard items, 3-7 weeks for custom orders.

Precision Ceramic Gauge Factory-ADCERAX

ADCERAX has worked in advanced ceramics for over 20 years and has developed 2,000+ types of precision components, including ceramic gauge blocks and related ceramic gauges made from zirconia (ZrO₂), alumina (Al₂O₃), and other engineering ceramics.

We supply standard ceramic gauge block sets, single replacements, and build-to-spec custom kits for shop-floor checks, inspection-room verification, comparator routines, height gauge referencing, and fixture/tooling setup, exporting to 50+ countries and supporting OEMs that require controlled grade/class targets, repeatable working-face geometry, and consistent marking/ID rules for reliable measurement programs.

One-Stop Manufacturing Services for Ceramic Gauge Blocks

ADCERAX provides an end-to-end manufacturing workflow for ceramic gauge blocks and related gauges, from engineering review to finishing and inspection. This process model reduces lead-time risk and keeps grade/class control, working-face geometry, and marking consistency stable across both standard sets and custom replacements.

confirms system (metric/inch), grade/class, size list, and ID rules

achieves controlled flatness, parallelism, and surface condition

keeps storage and handling clean for inspection-room routines

builds a dense, stable ceramic body for dimensional finishing

reduces handling-related chipping risk during daily use

verifies critical dimensions and documentation before shipment

Technical Competence and Manufacturing Strength

ADCERAX maintains strong engineering capability with traceable workflows for ceramic gauge blocks and pin,ball,ring ceramic gauges. Our facility integrates forming, sintering, precision grinding/lapping, and inspection to support repeatable verification programs.

| Parameter | Capability | Engineering Note |

|---|---|---|

| Grade / Class Control | Grade 1 / 0 / 00 / K (as specified) | Accuracy is defined by the selected grade/class for your inspection or calibration workflow. |

| Length Tolerance (ISO 3650) | Typical limit deviation (±te): 0.12–0.60 µm (Grade 0, 0.5–100 mm) | Used as the primary acceptance window for nominal length accuracy; confirm target grade and length range. |

| Length Variation (ISO 3650) | Typical variation (tv): 0.10–0.20 µm (Grade 0, 0.5–100 mm) | Controls uniformity across the measuring face for repeatable comparator and stacking routines. |

| Working-Face Geometry | Flatness tolerance (tf): 0.10 µm (Grade 0, 0.5–150 mm) | Flatness/parallelism are controlled to support consistent contact behavior and stable verification results. |

| Inspection & Traceability | µm-level dimensional verification with records | Verifies length, working-face condition, marking/ID, and release documentation for sets and single replacements. |

FAQs About Ceramic Gauge

The key differences are material behavior and maintenance requirements. Ceramic blocks do not rust and are non-magnetic, which helps keep handling and contact routines stable in environments where steel can develop oil-film variation, corrosion marks, or magnetic attraction effects. Steel can still be preferred for certain legacy workflows or cost-driven applications.

Most ceramic gauge blocks are made from zirconia (ZrO₂) because it provides a stable ceramic body for precision finishing and daily handling. Some customers also specify alumina (Al₂O₃) for cost structure and general metrology use, depending on their workflow and acceptance criteria.

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts. Separated they live in Bookmarksgrove right at the coast

Yes. Many customers buy a standard set for daily use and then order single replacements to maintain completeness after loss, wear, or handling damage. Replacement programs work best when marking/ID rules and case layout are kept consistent across purchases.

Common configurations include 32-piece and 47-piece sets for general inspection, and 81-piece sets for broader coverage and more flexible build-ups. Some buyers also use expanded sets (such as 87-piece or 103-piece) depending on regional practice and the nominal length range required.

Wringing is the ability of two gauge blocks to adhere by intimate contact between clean, flat faces. Ceramic gauge blocks can wring when their working faces are properly finished and handled cleanly. In practice, repeatable wringing depends as much on cleaning, technique, and surface condition control as on the material itself.

Most users specify lapped working faces suitable for stable comparator readings and consistent build-ups. If your workflow is sensitive to residue and contact repeatability, you should define surface condition expectations and handling rules, especially when ceramic gauge will be shared across multiple operators and stations.

They can be, provided you manage handling and storage properly. Many users prefer ceramic blocks where rust prevention is burdensome or where magnetic attraction can affect handling consistency. For harsh shop-floor environments, protective case layout, clear labeling, and a simple cleaning routine are important to preserve reference integrity.

Store ceramic gauge in a protective case with labeled positions to prevent mixing and reduce edge contact. Handling should control residue and staining, and contact faces should be kept clean and dry. A consistent routine across operators improves repeatability and reduces the risk of damage or inconsistent results.

Common issues include contact face contamination, inconsistent cleaning routines, damaged edges from handling, mixed sets or lost traceability due to unclear labeling, and mismatched grade/class selection that does not align with the verification requirement. Many “accuracy problems” are workflow problems rather than material problems.

Send the measurement system (metric or inch), whether you need a set or singles, the target grade/class (Grade 1/0/00/K), your size list and quantity, marking/ID rules, certificate needs, preferred case layout, and ship-to country. With these details, we can recommend a practical set structure or replacement plan and quote accurately.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

info@adcerax.com

Telephone: +(86) 0731-74427743

WhatsApp: +(86) 19311583352

Within 24 hours

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.