ADCERAX® Yttria Stabilized Zirconia Tube Open Both Ends is engineered for applications that demand extreme thermal stability, corrosion resistance, and long service life. These tubes are widely used in industrial furnaces, chemical reactors, thermocouple sheaths, and laboratory systems where precision and durability are critical.

By combining dense crystalline structure with high fracture toughness, they maintain reliable performance under repeated high-temperature cycles. With standard models in stock and custom production available, ADCERAX ensures that Yttria Stabilized Zirconia Ceramic Tube meet diverse industrial requirements.

Features of Yttria Stabilized Zirconia Tube Open Both Ends

The Yttria Stabilized Zirconia Tube Open Both Ends is designed for applications requiring high strength, thermal resistance, and corrosion stability. Verified physical and mechanical data ensure consistent performance in furnaces, chemical systems, and laboratory use.

- Temperature resistance up to 1000°C allows safe long-term operation in heating systems.

- Thermal conductivity of 3 W/m·K provides efficient thermal control under load.

- Thermal expansion coefficient of 1.0 ×10⁻⁵ /°C supports dimensional stability under repeated cycles.

- Bending strength ranges from 480–1000 MPa, suitable for industrial stress conditions.

- Compressive strength between 1600–2300 MPa ensures durability under pressure.

- Hardness of 1200–1450 HV1 guarantees excellent wear resistance during use.

Technical Properties for Yttria Stabilized Zirconia Tube Open Both Ends

The Yttria Stabilized Zirconia Tube Open Both Ends delivers measurable reliability through precise physical, chemical, and mechanical properties. This section highlights the verified technical data and connects directly to the detailed parameter table and the available size specifications.

| Property | Specification |

| Density | 5.65–6.05 g/cm³ |

|

Thermal conductivity |

3 W/m·K |

| Thermal expansion | 1.0 ×10⁻⁵ /°C |

|

Maximum service temperature |

1000°C |

|

Bending strength |

480–1000 MPa |

|

Compressive strength |

1600–2300 MPa |

|

Fracture toughness |

6–8 MPa·m½ |

|

Hardness |

1200–1450 HV1 |

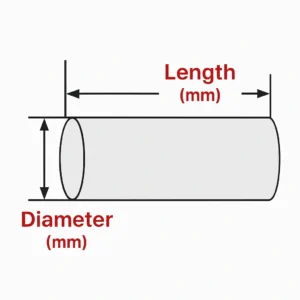

Dimensions of Yttria Stabilized ZrO2 Ceramic Tube Open Both Ends

| Model | Outer Diameter (mm) | Inner Diameter (mm) | Length (mm) |

| AT-YHG-G001 | 0.7 | 0.3 | ≤100 |

| AT-YHG-G002 | 0.8 | 0.4 | |

| AT-YHG-G003 | 0.9 | 0.4 | |

| AT-YHG-G004 | 1 | 0.5 | ≤300 |

| AT-YHG-G005 | 1.1 | 0.6 | |

| AT-YHG-G006 | 1.2 | 0.6 | |

| AT-YHG-G007 | 1.3 | 0.7 | |

| AT-YHG-G008 | 1.4 | 0.8 | |

| AT-YHG-G009 | 1.5 | 0.8 | |

| AT-YHG-G010 | 2.0 | 1.0 | ≤500 |

| AT-YHG-G011 | 3.0 | 1.5 | |

| AT-YHG-G012 | 3.0 | 2.0 | |

| AT-YHG-G013 | 4.0 | 2.0 | |

| AT-YHG-G014 | 4.0 | 3.0 | |

| AT-YHG-G015 | 5.0 | 3.0 | |

| AT-YHG-G016 | 5.0 | 3.5 | |

| AT-YHG-G017 | 6.0 | 4.0 | |

| AT-YHG-G018 | 7.0 | 4.5 | |

| AT-YHG-G019 | 8.0 | 4.0 | |

| AT-YHG-G020 | 8.0 | 5.0 | |

| AT-YHG-G021 | 9.0 | 6.0 | |

| AT-YHG-G022 | 10.0 | 4.0 | |

| AT-YHG-G023 | 10.0 | 6.0 | |

| AT-YHG-G024 | 10.0 | 7.0 | |

| AT-YHG-G025 | 12.0 | 4.0 | ≤600 |

| AT-YHG-G026 | 12.0 | 8.0 | |

| AT-YHG-G027 | 14.0 | 4.0 | |

| AT-YHG-G028 | 14 | 10 | |

| AT-YHG-G029 | 15 | 11 | |

| AT-YHG-G030 | 16 | 12 | |

| AT-YHG-G031 | 18 | 14 | |

| AT-YHG-G032 | 17.5 | 11.1 | |

| AT-YHG-G033 | 20 | 15 | |

| AT-YHG-G034 | 25 | 19 | |

| AT-YHG-G035 | 30 | 25 | |

| AT-YHG-G036 | 40 | 30 | |

| AT-YHG-G037 | 44 | 38 | |

| AT-YHG-G038 | 50 | 40 | |

| AT-YHG-G039 | 60 | 50 | |

| AT-YHG-G040 | 70 | 60 | |

| AT-YHG-G041 | 80 | 70 | |

| AT-YHG-G042 | 90 | 80 | |

| AT-YHG-G043 | 100 | 90 |

Packaging for Yttria Stabilized Zirconia Tube Open Both Ends

The Yttria Stabilized Zirconia Tube Open Both Ends is securely packed in reinforced cartons with protective padding to prevent surface damage. Each carton is further stabilized with wooden crates to ensure safe handling during long-distance transport. This packaging method guarantees that the YSZ Tube Open Both Ends arrives intact and ready for immediate use.