Silicon Carbide Wafer Handling Furnace Components for High-Stability Thermal Processing by ADCERAX®

Highly engineered Silicon Carbide Wafer Handling Furnace Components enable stable wafer support, predictable thermal behavior, and controlled gas-flow uniformity across demanding furnace environments. Their rigid SiC structures help reduce wafer slip, thermal deformation, and contamination throughout continuous processing cycles.

Choose ADCERAX® to request detailed component specifications for your production needs.

1500°C

Thermal Stability

What Are Silicon Carbide Wafer Handling Furnace Components?

SiC wafer handling components are precision-formed carriers used to load, support, and stabilize wafers inside high-temperature diffusion, oxidation, and LPCVD furnace systems. They control wafer spacing, minimize deformation, and maintain stable thermal environments during long processing cycles.

Their SiC structure offers high rigidity and predictable thermal response under repeated 900–1500°C operations. These components are essential in PV cell diffusion lines and compound semiconductor thermal processing equipment.

Technical Specification of ADCERAX® Silicon Carbide Wafer Handling Furnace Components

These specifications summarize the structural, mechanical, and thermal characteristics required for diffusion and oxidation furnace loading systems. Values correspond to typical RBSiC/SSiC configurations used in PV and semiconductor production environments.

| Parameter | Specification |

|---|---|

| Material System | Reaction-Bonded SiC (RBSiC) / Sintered SiC (SSiC) |

| Maximum Operating Temperature | 1400–1500°C continuous |

| Thermal Conductivity | 120–170 W/m·K |

| Coefficient of Thermal Expansion (CTE) | ~4.2 × 10⁻⁶ /K |

| Flexural Strength | 220–320 MPa range |

| Elastic Modulus | 300–420 GPa |

| Density | 3.05–3.15 g/cm³ |

| Open Porosity | <1% typical |

| Slot Pitch Tolerance | ≤0.05–0.10 mm |

| Flatness / Straightness | ≤0.10 mm per 200–300 mm span |

| Surface Roughness | Ra 0.2–0.8 μm |

| Shock Resistance | ΔT up to 250°C |

| Chemical Compatibility | Oxidizing, inert, and vacuum atmospheres |

Properties of ADCERAX® SiC Wafer Handling Furnace Components

These components enable stable wafer positioning under high thermal gradients and are widely used in PV and semiconductor furnace systems. Their dimensional consistency, creep resistance, and structural rigidity ensure precise wafer geometry retention throughout long-cycle heating environments.

Structural and Dimensional Stability

Dimensional performance is maintained under prolonged high-temperature processing.

- Low Thermal Drift: stable geometry at 1400°C

- Slot Pitch Accuracy: controlled spacing within 0.05 mm

- Low Deformation Rate: stable after 500+ cycles

Material Purity and Thermal Reliability

Thermal shock resistance and chemical cleanliness are ensured during continuous furnace cycling.

- Shock Resistance Value: stable after ΔT 250°C

- Chemically Inert SiC: compatible with oxidizing atmospheres

- High Cycle Lifetime: operation beyond 12–36 months

Furnace Integration Compatibility

Component geometry maintains stable positioning in PV furnace operation.

- Stable Thermal Behavior: maintains form during cycling

- Optimized Gas Pathway: improves flow across wafers

- Uniform Slot Geometry: supports precise wafer alignment

Mechanical Strength Endurance

Mechanical integrity is maintained under prolonged furnace cycling and high wafer loading conditions.

- High Flexural Strength: stable at 250 MPa rating

- Creep Resistance Level: minimal drift after 1000 cycles

- Load Distribution Control: uniform support across carriers

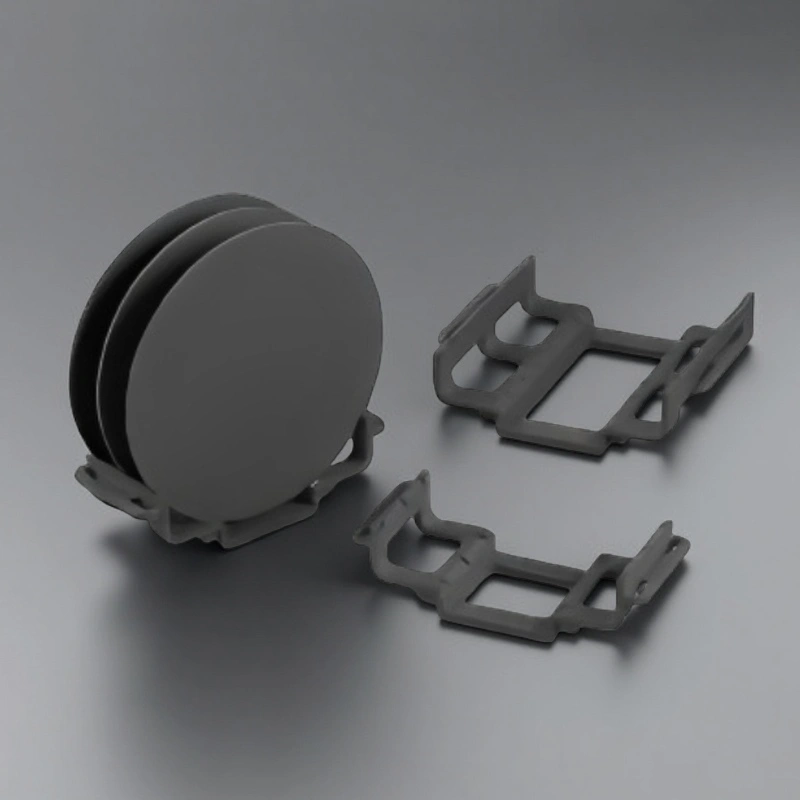

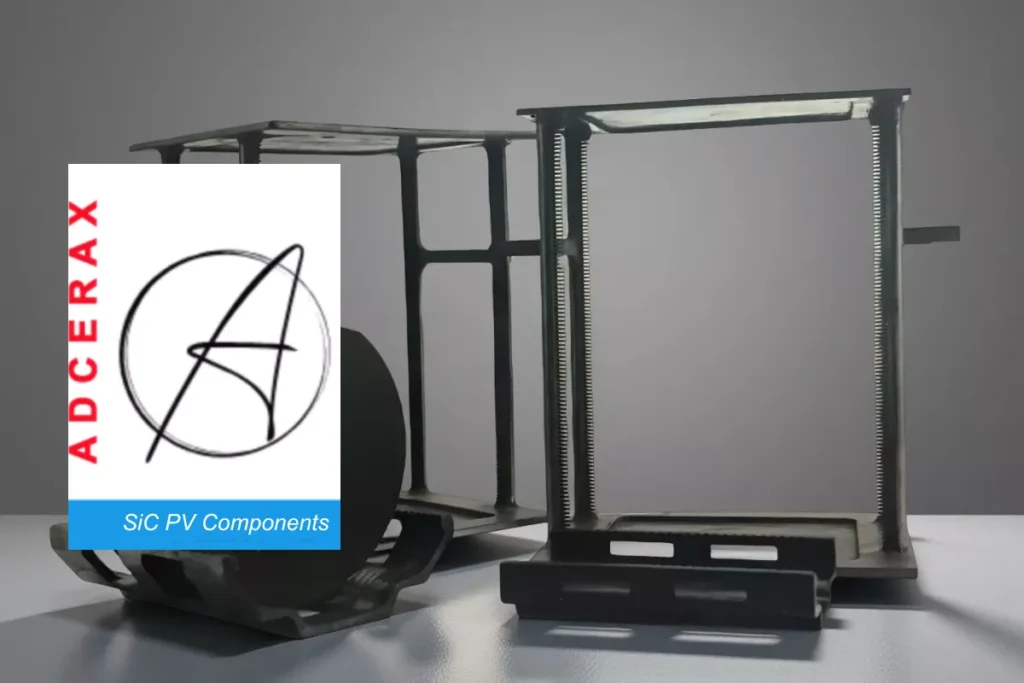

ADCERAX® SiC Wafer Handling Furnace Components Product Range

Silicon Carbide Wafer Boat provides aligned wafer slot geometry and stable spacing during high-temperature diffusion and oxidation cycles.

- Precision slot pitch: spacing within 0.05 mm

- Thermal rigidity level: stable after 500 cycles

- Gas flow geometry: optimized diffusion path stability

- Load bearing stability: reinforced under full load

Silicon Carbide Boat Bracket maintains accurate mounting positions and stabilizes SiC boats inside thermal furnace chambers.

- Bracket fit accuracy: interface within 0.10 mm

- High span strength: drift under 300 mm load

- Furnace mount stability: secure seating under load

- Thermal stress control: predictable ΔT response maintained

Silicon Carbide Cantilever Paddle delivers long-span wafer support and minimized deflection for horizontal diffusion systems.

- Flexural modulus level: stiffness above 300 GPa

- Thermal gradient control: uniform heating distribution

- Low vibration response: reduced micro-motion

- Secure wafer seating: stable placement maintained

How Can ADCERAX® Assist Your Furnace Project?

Comprehensive support for Silicon Carbide Wafer Handling Furnace Components is provided through precise material selection, geometry optimization, and compatibility evaluation for diffusion, oxidation, LPCVD, and photovoltaic furnace systems.

Tailored component configurations ensure stable furnace operation, predictable thermal response, and process efficiency across demanding high-temperature environments.

For specialized engineering requirements, ADCERAX® delivers prompt technical coordination to accelerate project implementation and specification alignment.

Applications of ADCERAX® SiC Wafer Handling Furnace Components

Silicon Carbide Wafer Handling Furnace Components operate across PV diffusion, oxidation, annealing, and PECVD lines where wafer stability, slot precision, and thermal uniformity directly influence throughput and cell conversion efficiency.

PV Diffusion Furnace Wafer Loading

PV diffusion process uses Silicon Carbide Wafer Boat assemblies to hold 100–210 mm wafers during 800–1250°C phosphorus diffusion cycles.

-

Slot Pitch Control

Maintains 0.05 mm spacing tolerance during heating. -

Thermal Shape Stability

Retains geometry after 500+ furnace cycles. -

Uniform Gas Path

Provides consistent flow under 1100°C conditions. -

Load Stack Alignment

Supports up to 300 stacked wafers reliably.

PV Oxidation Furnace Support Structure

PV oxidation lines rely on Silicon Carbide Boat Bracket assemblies to stabilize wafer carriers during 900–1100°C oxide growth.

-

Bracket Fit Accuracy

Keeps interface deviation within 0.10 mm. -

High Span Rigidity

Controls deflection under 300 mm spans. -

Thermal Gradient Stability

Remains uniform across 900–1100°C cycles. -

Cycle Life Durability

Maintains structural integrity after 1000 cycles.

PV PECVD Pre-Load Transfer and Handling

PV PECVD systems use Silicon Carbide Cantilever Paddle components to transfer wafers through pre-deposition heating and loading zones.

-

Long-Span Rigidity

Maintains displacement stability under 300 GPa stiffness. -

Thermal Shock Control

Handles ΔT changes up to 300°C. -

Low Vibration Response

Reduces micro-motion during transfer. -

Alignment Consistency

Holds plane deviation below 0.10 mm.

One-Stop Engineering & Supply Capability by ADCERAX®

ADCERAX® Integrated One-Stop Service System

As a Silicon Carbide Wafer Handling Furnace Components factory, full-chain processing is coordinated from material forming to dimensional metrology to meet complex PV furnace design requirements.

This integrated service framework enables precise replication of furnace-specific geometries and ensures predictable performance under 700–1500°C PV thermal conditions.

-

Design Matching Support

optimized for furnace layout alignment -

Geometry Validation Assistance

verified with CMM dimensional mapping -

Thermal Behavior Simulation

tested under 700–1500°C cycles -

Cycle Durability Assurance

stability maintained beyond 1000 cycles -

PV Line Compatibility

adapted to diffusion oxidation PECVD

ADCERAX® Factory Manufacturing Capabilities

Manufacturing strength for silicon carbide balls relies on a controlled process chain combining precision shaping, ultra-high-temperature sintering, and metrology-grade inspection. Consistency delivered by leading silicon carbide ball factories is sustained through equipment accuracy, batch-tracking discipline, and tightly monitored microstructural uniformity.

| Manufacturing Capabilities Overview | |||

|---|---|---|---|

| Capability | Representative Data / Equipment Metric | ||

| Five-Axis CNC Machining Center | Tolerance repeatability: ±0.01 mm across 600 mm travel | ||

| Diamond Grinding System | Surface finish capability: Ra 0.2–0.6 μm functional surfaces | ||

| High-Temperature Sintering Furnace | Operating ceiling: 1700°C with controlled ramp profiles | ||

| Ultrasonic Precision Cleaning Line | Contaminant removal rate: >98% on SiC micro-features | ||

| Coordinate Measuring Machine (CMM) | Linear accuracy: 0.002–0.004 mm over key sections | ||

customized silicon carbide Wafer Handling Furnace Components supplier

We specialize in customizing silicon carbide wafer handling furnace components with special sizes, tight tolerances, and complex features.

OEM and small-batch support available.

Customization Options

Extra-large / Extra-small diameters, non-standard thicknesses, and ultra-long / ultra-short lengths.

Provide higher - level dimensional accuracy and concentricity control than the standard.

Flanges, steps, threads, drilling holes, grooves, etc.

Adjust the material according to the application requirements.

Polish and grind the surface to achieve a specific surface roughness.

Customization Process

Send us your drawing, CAD file, or physical sample with material grade, dimensions, tolerances, and quantity. Our engineers will evaluate the design and provide a detailed quotation with lead time and pricing.

Once the quote is approved, we proceed with sample prototyping (1–50 pcs) if needed, for testing and validation.

After sample approval or direct confirmation, we begin batch manufacturing using CNC machining, sintering, and polishing. All parts undergo dimensional checks, material purity testing, and surface finish inspection.

Finished products are securely packed and shipped via DHL/FedEx/UPS or your preferred method. We support global delivery with full documentation.

FAQs About ADCERAX® Silicon Carbide Wafer Handling Furnace Components

A sintered SiC wafer boat provides near-zero porosity and maintains structural accuracy at temperatures above 1400°C. This material maintains slot pitch stability, allowing diffusion furnaces to preserve wafer alignment over 500+ cycles. Its creep resistance prevents long-span deformation commonly seen in porous ceramics. As a result, Silicon Carbide Wafer Handling Furnace Components based on SSiC ensure long-term geometric reliability.

A high-purity SiC wafer boat minimizes contamination risks during oxidation and annealing processes. The absence of free silicon and impurities reduces particle shedding and surface reactions at 900–1100°C. This improves oxide film uniformity on wafers and lowers the probability of micro-scratches during thermal cycling. Therefore, high-purity configurations enhance the stability of Silicon Carbide Wafer Handling Furnace Components in PV oxidation furnaces.

A vertical diffusion furnace SiC wafer boat supports wafers in a stacked orientation that relies heavily on pitch uniformity and thermal equalization. Its SiC microstructure maintains predictable expansion behavior across 1100–1250°C. This prevents slot drift, wafer tilt, and uneven dopant diffusion. The structural rigidity strengthens the overall performance of Silicon Carbide Wafer Handling Furnace Components in vertical furnace environments.

A SiC cantilever beam provides long-span rigidity that resists bending during automated wafer loading. Its modulus above 300 GPa stabilizes wafer stacks even during rapid transport motions. This reduces vibration-induced micro-cracks and protects thin PV wafers. With these advantages, the cantilever beam becomes a critical element within Silicon Carbide Wafer Handling Furnace Components.

An advanced SiC cantilever paddle withstands ΔT up to 300°C, limiting thermal shock damage during transfer. Its low thermal expansion ensures precise wafer seating and prevents gradual deflection across many cycles. Surface inertness helps minimize particle contamination before PECVD deposition. These factors significantly improve the performance of Silicon Carbide Wafer Handling Furnace Components during pre-process heating.

SiC components retain dimensional stability due to low CTE values around 4.0–4.5×10⁻⁶/K. This allows slot pitch tolerance to remain within approximately 0.05 mm throughout repeated cycles. Stable geometry directly enhances dopant uniformity in phosphorus diffusion. The precision reduces wafer tilt and prevents edge slip during high-stress thermal stages.

High flexural strength (typically 250–450 MPa depending on grade) minimizes creep deformation. Dense SiC microstructures distribute thermal loads evenly across extended spans. The combination limits bowing effects during prolonged 900–1100°C oxidation cycles. These properties make the components stable under heavy wafer stacks.

SiC carriers maintain flatness and straightness within tight tolerances, lowering mechanical stress on thin wafers. High thermal shock resistance prevents micro-fracture initiation during rapid temperature swings. Stable seating reduces localized point loading that often leads to breakage. The result is improved mechanical survival across large-scale PV handling cycles.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.

Partner with ADCERAX for SiC Wafer Handling Furnace Components

Looking for a reliable Silicon Carbide Wafer Handling Furnace Components supplier? Let us help you with your next project.

info@adcerax.com

Tel.:

+(86) 0731-74427743

WhatsApp:

+(86)19311583352

Within 24 hours