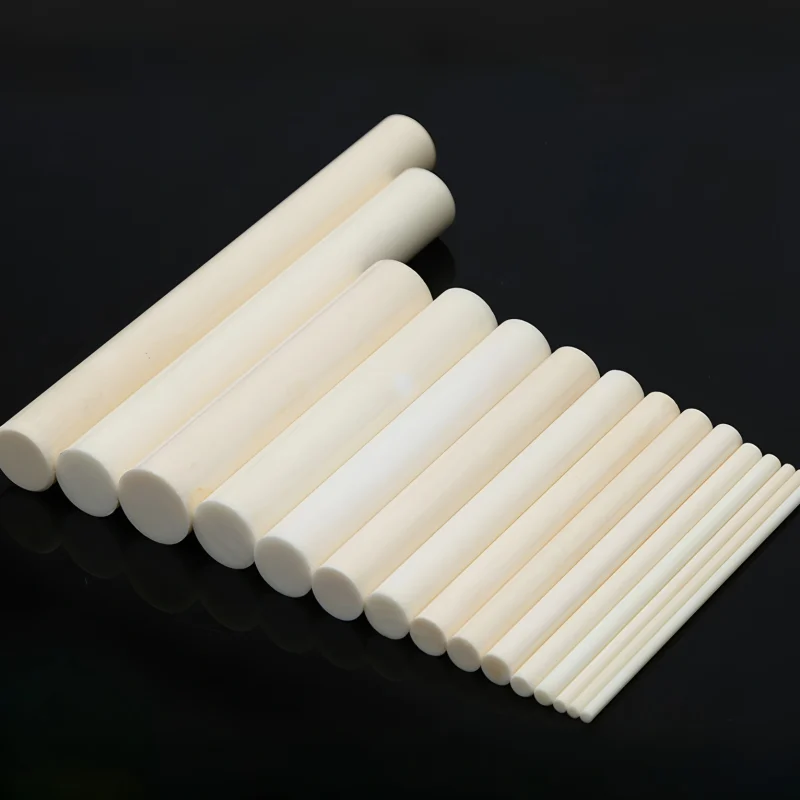

Industrial Ceramic Rod & Bar Solutions for High-Temperature and Insulation Use

ADCERAX manufactures industrial ceramic rods & bars for furnace fixtures, electrical insulation structures, guide and wear parts, and chemical processing equipment, using high-purity alumina, zirconia, silicon carbide, silicon nitride and machinable glass-ceramic. We keep selected ceramic rod stock and round bar blanks in common diameters for quick cut-to-length supply, and produce engineered custom ceramic rods with ground or polished surfaces, controlled tolerances and special features according to your drawings and operating conditions.

Choose ADCERAX as your ceramic rod and bar partner to stabilize production, extend component life and reduce total maintenance costs.

Ceramic Rod Definition

Ceramic rods are straight engineered components used as supports, guides, standoffs and wear parts in industrial equipment. Made from alumina, zirconia, silicon nitride, silicon carbide and machinable ceramics, they offer high-temperature stability, electrical insulation and resistance to corrosion and abrasion. With suitable material, diameter and finish, rods can be matched to furnace fixtures, heaters, automation systems, chemical lines and laboratory devices.

Key Performance Advantages of ADCERAX Ceramic Rods

ADCERAX designs ceramic rods and ceramic bars for furnace fixtures, heater assemblies, electrical insulation, guides and process equipment where stable geometry and long service life are critical.

Reliable At Elevated Temperatures

Alumina, silicon carbide, zirconia and silicon nitride rods retain strength and stiffness at high temperature. Fixtures, supports and guide elements stay straight so heating zones and chambers remain dimensionally stable.

Dimensional Accuracy And Shape Stability

Controlled sintering and precision grinding deliver tight diameter, length and straightness tolerances. Assemblies fit repeatably, reducing vibration, leakage and misalignment during operation over long service life.

Clean, Low-Contamination Contact Surfaces

High-purity ceramic rods with smooth surfaces shed few particles and resist reaction with process media. They are well suited to heat treatment lines, laboratory equipment and other clean process applications.

Corrosion And Wear Protection For Process Media

Ceramic rods withstand oxidation, chemical attack and abrasive particles in valves, pumps, linkages and guide tracks. They suit aggressive gases, powders, slurries and process liquids where long replacement intervals matter.

Resistance To Thermal Shock And Cycling

Optimized microstructures and firing give rods good resistance to fast heat-up and cool-down. This helps limit cracking in furnace fixtures, burner-area anchors and other thermally cycled components exposed to repeated cycles.

High Electrical Insulation In Hot Zones

Oxide and nitride ceramics provide strong dielectric performance. Ceramic rods work as insulating standoffs, support posts and isolation bars in high-voltage or high-temperature assemblies without extra insulation sleeves.

Properties of Ceramic Rod

Ceramic rods are produced from high-purity alumina, with additional options in zirconia, silicon nitride, silicon carbide and boron nitride. These materials combine strength, thermal shock resistance, electrical insulation and chemical stability for demanding furnace, heater, guide and process-line duties.

Alumina Ceramic Rod

Higher alumina purities improve density, hardness, dielectric strength and maximum use temperature, while lower grades offer more cost-effective performance for general supports and fixtures.

| Property | Unit | 96% Al₂O₃ | 99% Al₂O₃ | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

|---|---|---|---|---|---|---|---|---|---|

| Alumina content | % | 96 | 99 | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.75 | 3.88 | 3.89 | 3.91 | 3.92 | 3.93 | 3.95 | 3.98 |

| Flexural strength | MPa | 330 | 360 | 379 | 312 | 313 | 314 | 315 | 320 |

| Hardness | GPa | 11.5 | 13.5 | 14.1 | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 20–25 | 30–35 | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | 150 | 200 | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1600 | ≤1700 | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Dielectric strength | kV/mm | 8–10 | 10–12 | 11–13 | 12–14 | 12–15 | 13–16 | 14–17 | 15–18 |

| Volume resistivity (25°C) | Ω·cm | ≥1×10¹³ | ≥1×10¹⁴ | ≥3×10¹⁴ | ≥5×10¹⁴ | ≥1×10¹⁵ | ≥3×10¹⁵ | ≥5×10¹⁵ | ≥1×10¹⁶ |

Zirconia Ceramic Rod

Zirconia rod offers high fracture toughness and strong wear resistance, ideal for stressed guides and positioning parts that must hold tight tolerances under load.

| Property | Specification |

| Maximum Working Temperature | 1500 °C continuous use |

| Density | 5.65 g/cm³ |

| Thermal Expansion Coefficient | 10.3 × 10⁻⁶/K (25–1000 °C) |

| Thermal Conductivity | 2.2 W/m·K at 1000 °C |

| Chemical Stability | 0.08% mass loss after 24 h acid/alkali exposure at 1200 °C |

| Flexural Strength | 900 MPa at room temperature |

| Fracture Toughness | 8 MPa·m½ |

| Hardness (Vickers) | 12 GPa |

| Elastic Modulus | 210 GPa |

Silicon Carbide Rod

Silicon carbide rod provides high hardness, wear and corrosion resistance, maintaining shape and surface integrity in hot, abrasive or chemically aggressive process conditions.

| Property | Specification |

|---|---|

| Material System | RBSiC (80% SiC, 20% free Si) / SSiC (≥99% SiC) |

| Maximum Operating Temperature | ≤1380°C (RBSiC) / ≤1600°C (SSiC) |

| Bulk Density | 3.02 g/cm³ (RBSiC) / 3.10 g/cm³ (SSiC) |

| Open Porosity | <0.1% |

| Flexural Strength (20°C) | 250 MPa (RBSiC) / 380 MPa (SSiC) |

| Flexural Strength (1200°C) | 280 MPa (RBSiC) / 400 MPa (SSiC) |

| Compressive Strength | 1000–2200 MPa |

| Elastic Modulus | 330 GPa (RBSiC) / 420 GPa (SSiC) |

| Thermal Conductivity | 45 W/m·K (RBSiC) / 74 W/m·K (SSiC) |

| Thermal Expansion Coefficient | 4.1–4.5 ×10⁻⁶/K |

| Hardness | 2600–2800 kg/mm² |

| Chemical Stability Range | pH 2–12 |

| Oxidation Stability | <1% microstructural oxidation after 50 cycles (1000°C → RT) |

Silicon Nitride Rod

Silicon nitride rod combines high flexural strength with outstanding thermal shock resistance, staying reliable under rapid heating and cooling in demanding mechanical or thermal cycling applications.

| SiN4 Type | Gas pressure sintering Si3N4 | Hot pressing sintering Si3N4 | High thermal conductivity Si3N4 |

|---|---|---|---|

| Density (g/cm³) | 3.2 | 3.4 | 3.5 |

| Texture strength (MPa) | 300 | 300-320 | 300-320 |

| Young Modulus | 300 | 300 | 300 |

| Poisson’s ratio | 0.25 | 0.25 | 0.25 |

| Hardness (GPa) | 15 | 15 | 15 |

| Maximum working temperature (°C) | 1100 | 1200 | 1200 |

| Thermal expansion coefficient (Mm/m·K) | 3 | 3 | 3 |

| Thermal conductivity (W/m·K) | 15 | 15 | 15 |

| Thermal shock resistance (ΔT °C) | 550 | 580 | 600 |

Ceramic Rod & Bar Products

Wear-resistant ceramic rods are selected by material, profile and duty. Here you can compare alumina, zirconia, silicon nitride, silicon carbide and other industrial ceramic rods—round, square, threaded or porous—for furnace fixtures, insulating supports, guides and process equipment.

alumina ceramic rod

Alumina rod for high-temperature insulation and support, with stable dimensions, strong dielectric strength and clean surfaces.

zirconia ceramic rod

Tough ZrO₂ rod for stressed positions, combining high fracture strength, tight tolerances and reliable thermal stability in service.

silicon carbide ceramic rod

Silicon carbide rod with high hardness and wear resistance, limiting chipping, abrasion and profile loss in service.

silicon nitride ceramic rod

Silicon nitride rod for extreme heat and rapid cycling, offering excellent thermal shock resistance and mechanical strength.

machinable ceramic rod

Easily machined rod for fast prototypes and fixtures, with good insulation, dimensional stability and clean surfaces.

Aluminum Nitride Rod

Aluminum nitride rod with high thermal conductivity and insulation, suited to heat-spreading supports in compact power assemblies.

Boron Nitride Rod

Boron nitride rod with non-wetting behavior and thermal shock resistance for release-friendly supports in molten metal tooling.

Beryllium Oxide Rod

Beryllium oxide rod combining very high thermal conductivity with strong insulation for specialist ports and compact power parts.

ceramic round bar

Round ceramic bar for general supports, guides and machining stock, offering smooth alignment and easy cutting to length.

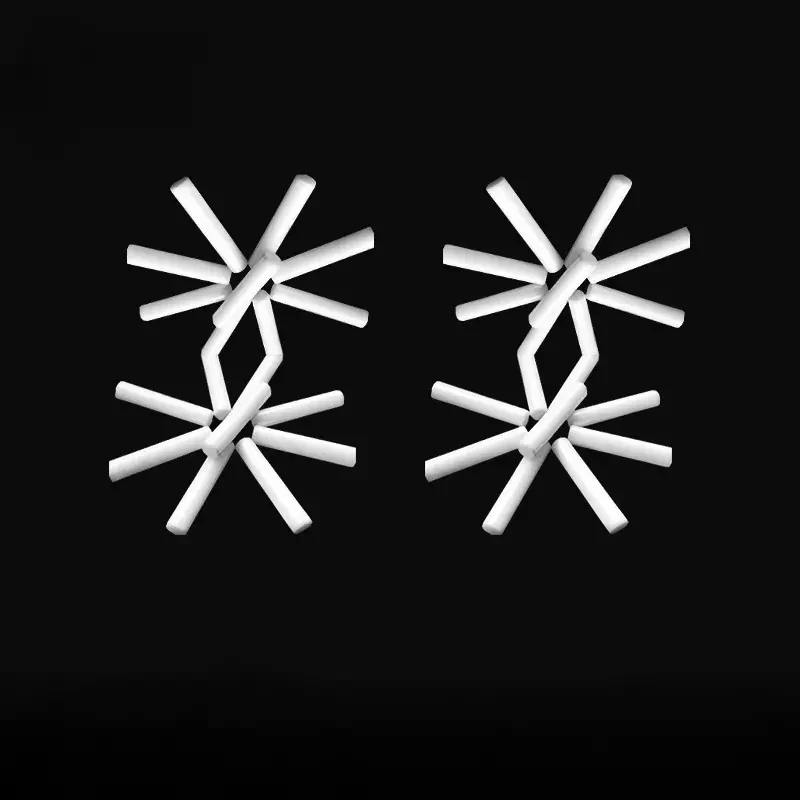

square ceramic rod

Square ceramic rod with flat faces for anti-rotation mounting and stable clamping in structural or insulating assemblies.

ceramic threaded rod

Ceramic threaded rod for fastening and adjustment, maintaining electrical isolation in hot or corrosive zones.

porous ceramic rod

Porous ceramic rod with permeability for wicking, gas diffusion or filtration under thermal or chemical stress.

One source for alumina, zirconia, silicon nitride and silicon carbide rods, from round bar stock to custom machined parts.

Share your drawing and key conditions—temperature, atmosphere, media and duty cycle—and we’ll recommend the most suitable ceramic rod material and geometry, ready for repeatable production.

Ceramic Rod & Bar Applications

Wear-resistant ceramic rods are used wherever fixtures, guides and insulating parts must stay stable under heat, load or aggressive media. The examples below help buyers quickly match material and shape to their real working conditions.

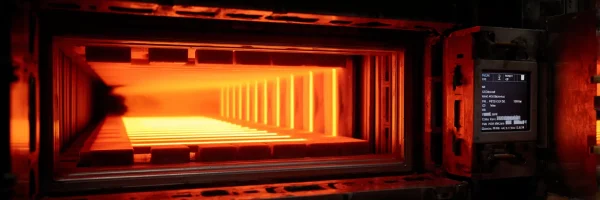

Furnace Fixtures and Kiln Furniture

🧩Where industrial ceramic rods are used:

Ceramic rod support refractory linings, burner tiles and product carriers in kilns and furnaces. They keep fixtures straight through repeated firing cycles, helping to control clearances, prevent sagging and maintain temperature uniformity.

🧩ADCERAX ceramic rods help keep beams, hangers and supports straight through repeated firing cycles, controlling clearances, limiting sagging and stabilizing temperature zones for more consistent firing results.

Electrical Insulation Posts and Standoffs

🧩Where industrial ceramic rods are used:

Alumina, zirconia and silicon nitride rods work as insulating standoffs, posts and cross-bars in heaters, power modules and sensor assemblies. They provide dielectric separation and mechanical support at elevated temperatures without extra insulation sleeves.

🧩ADCERAX ceramic bars provide reliable dielectric separation and mechanical strength in hot zones, allowing compact layouts while maintaining creepage distances and long-term insulation performance.

Chemical and Fluid Handling Components

🧩Where industrial ceramic rods are used:

Corrosion-resistant ceramic rods and bars reinforce valves, pump linkages, mixer shafts and contact points exposed to aggressive gases, slurries and process liquids. They maintain geometry where metallic parts may corrode, swell or erode.

🧩ADCERAX ceramic rods maintain geometry and surface integrity where metallic parts may corrode or erode, helping equipment hold sealing forces and flow accuracy over longer service life.

Guide Rods, Alignment Pins and Wear Protection

🧩Where industrial ceramic rods are used:

Tough ceramic rods are used as guide pins, locating elements and sliding supports in automated equipment. Their hardness and wear resistance help hold alignment, reduce play in moving parts and extend the service interval in abrasive or high-cycle mechanisms.

🧩ADCERAX ceramic bars offer high hardness and wear resistance, keeping alignment stable, reducing play in moving parts and extending maintenance intervals in abrasive or high-cycle mechanisms.

Industrial R&D, Prototyping and Test Rigs

🧩Where industrial ceramic rods are used:

Machinable ceramic rods and standard bar stock provide convenient blanks for fixtures, sample holders and test jigs in laboratories and pilot lines. Engineers can machine or cut rods to size quickly, then move to higher-performance grades for repeatable production.

🧩ADCERAX ceramic bars give engineers fast access to machinable prototypes and higher-performance production grades from the same supplier, shortening development time and simplifying the transition from trial parts to repeatable production.

Custom Ceramic Rod Supplier

ADCERAX is a China ceramic rod manufacturer specialising in custom-made rods and bars for industrial equipment and laboratory furnaces. We tailor diameter, bar profile, length, material grade and end features to your drawings, while keeping key standard ceramic rod sizes in stock for urgent maintenance and small projects.

Customization Options

Extra-large / Extra-small diameters, non-standard thicknesses, and ultra-long / ultra-short lengths.

Provide higher - level dimensional accuracy and concentricity control than the standard.

Flanges, steps, threads, drilling holes, grooves, etc.

Adjust the material according to the application requirements.

Polish and grind the surface to achieve a specific surface roughness.

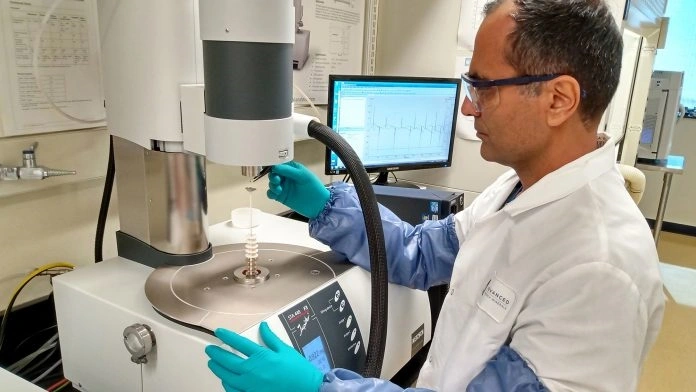

Customization Process

Send us your drawing, CAD file, or physical sample with material grade, dimensions, tolerances, and quantity. Our engineers will evaluate the design and provide a detailed quotation with lead time and pricing.

Once the quote is approved, we proceed with sample prototyping (1–50 pcs) if needed, for testing and validation.

After sample approval or direct confirmation, we begin batch manufacturing using CNC machining, sintering, and polishing. All parts undergo dimensional checks, material purity testing, and surface finish inspection.

Finished products are securely packed and shipped via DHL/FedEx/UPS or your preferred method. We support global delivery with full documentation.

ADCERAX: A Reliable Source for Industrial Ceramic Rods

ADCERAX is a dedicated industrial ceramic rod manufacturer, offering a full range of standard and custom rods with managed material quality and precise dimensions. Our engineering team, sampling service and export experience simplify global sourcing.

Competitive pricing with strict quality control from raw material sourcing to final delivery

Professional team providing comprehensive technical support and collaborative design

Small batch orders to large-scale production with complex geometries and tight tolerances

24-hour response and 24-hour dispatch for standard items, 3-7 weeks for custom orders.

China Industrial Ceramic Rod Factory-ADCERAX

ADCERAX has been engaged in advanced ceramics for over 20 years and has developed more than 2,000 types of high-temperature components, with a strong focus on wear-resistant ceramic bars & ceramic rods made from high-purity alumina, zirconia, silicon nitride, silicon carbide, boron nitride and other engineering ceramics.

We supply both custom and standard ceramic rods for laboratory equipment, furnace fixtures, heater supports, thermocouple protection hardware, guides, standoffs and high-temperature process lines, exporting to more than 50 countries and supporting industrial users and OEMs that require stable, low-contamination and long-life ceramic rod performance.

Ceramic Rod Processing Strength

ADCERAX controls every step, from forming to finishing, to keep ceramic rod diameter, length and straightness consistent. Tuned sintering profiles and 100% visual checks for cracks deliver strong, thermal-shock-resistant ceramic rods and bars that run reliably through many furnace and process cycles.

CNC Forming Stability & Diameter Control

Dimensional accuracy for ceramic rods is achieved through CNC-assisted forming and machining, keeping diameter, length and straightness within tight, repeatable tolerances for secure fits and stable heating or guiding paths.

Holding ceramic rod diameters within narrow limits supports stable mounting, insulation performance and mechanical strength along the full length.

Controlling cut length and tolerances ensures rods seat accurately in housings, guides and fixtures, reducing play, leakage and misalignment.

Managing bow and end squareness keeps rods aligned in furnaces, heaters and machines, improving assembly stability and service life.

Clean, Low-Contamination Surface Finishing

External ceramic rod surfaces are refined to reduce residue build-up, minimize contamination and limit micro-cracks, helping each heating or process cycle stay stable and easy to maintain.

Optimised surface roughness reduces particle generation and wear while maintaining good contact with metals, seals or supports.

Removing sharp rims and micro-chips at rod ends cuts the risk of handling damage, assembly cracks and local stress spikes.

Applying selected finishes where needed lowers porosity, eases cleaning and reduces reaction with process atmospheres or media.

High-Temp Sintering for Service Life & Thermal Shock Resistance

Microstructure density and strength in ceramic rods are developed through controlled high-temperature sintering, tuned to each material for long life under repeated heating and cooling.

Managing ramp and cool-down rates balances strength, residual stress and resistance to cracking in rapid-cycle service.

Matching soak times and peak temperatures to alumina, zirconia, Si₃N₄ and SiC bodies helps each grade reach its designed properties.

Low open porosity improves stability and cuts gas or media permeability over service cycles, helping ceramic rods keep their strength and straightness.

Precision & Tolerance of ADCERAX Ceramic Rods

ADCERAX supplies ceramic rods from fine pins up to larger bar stock, depending on material and process. Ground diameters can typically be held to ±0.01 mm or better to achieve repeatable slip, clearance or interference fits with metal housings and guides.

Rod lengths are matched to your assembly, from short spacers to long furnace or guide rods. We control overall length and bow so parts seat squarely in fixtures and maintain alignment over the full working span.

Ends can be ground square, chamfered or radiused to reduce edge chipping and ease assembly. Where needed, we offer refined or polished surfaces to support low-friction sliding, sealing or reduced particle generation.

FAQs About Ceramic Rods & Bars

A high temperature ceramic rod is a straight engineering-ceramic component, typically alumina, zirconia, silicon nitride or silicon carbide, used as a structural support, guide, standoff or wear element where high temperature, insulation or corrosion resistance are required.

Start from the working conditions—temperature, atmosphere, mechanical load, electrical requirements and media—then match these to material properties such as strength, thermal shock behaviour, dielectric strength and corrosion resistance.

Common grades include alumina for general high-temperature insulation, zirconia for toughness and wear, silicon nitride for strength and thermal shock resistance, silicon carbide for abrasion and corrosive media, and machinable ceramic rods for fast prototyping and small custom fixtures.

Wear resistant ceramic rods are preferred when the part must withstand high temperature, provide electrical insulation, resist corrosion or abrasion, or maintain dimensional stability where metals creep, oxidize or conduct electricity.

Yes, we specialize in providing Custom Ceramic Rods tailored to your specific requirements. We can manufacture Ceramic Rods in non-standard diameters, lengths, complex shapes (such as stepped, drilled, or grooved rods), and with extremely strict dimensional tolerances based on your technical drawings.

Feasible diameters range from very small pins up to larger bars, with length and straightness tailored to the design. Ground rods can hold tight diameter and length tolerances; sharing your target fit and function lets us confirm realistic values.

We typically need material, diameter or profile, length, tolerances, surface finish, any special end features, operating conditions (temperature, load, media) and required quantity or annual usage.

Cleaning depends on what is on the surface and how critical the rod is in your assembly, but you can follow these basic guidelines:

Use non-abrasive tools

Use a soft cloth, sponge or nylon brush with suitable solvent or mild detergent. Avoid metal scrapers or hard brushes that can chip edges or scratch ground surfaces.Support the rod during cleaning

Support the rod along its length so it is not bent or stressed while you wipe or brush it, especially for long, slender ceramic rods.Rinse and dry carefully

Rinse thoroughly to remove cleaning residues and loose particles, then allow the rod to dry at room temperature or with gentle warming to avoid thermal shock.Avoid aggressive methods on critical surfaces

For rods used as precise guides, seals or insulating standoffs, avoid sandblasting, heavy grinding or high-pressure washing unless you have confirmed the method with your supplier.Consult the supplier for strong chemicals

If you plan to use strong acids, alkalis or specialised cleaners, check material compatibility and cleaning procedure with the ceramic rod manufacturer before use.

Cutting ceramic rod is not like sawing metal or plastic. Ceramics are hard and brittle, so the goal is to minimize stress and edge chipping while achieving the required length.

Prefer factory cut-to-length for precision

For tight length tolerances, square ends and repeatable pieces, it is usually safer to order cut-to-length ceramic rods from the manufacturer. This allows controlled cutting, grinding and chamfering under proper fixtures and inspection.Use suitable tools and support

If you must cut in-house, treat it as an abrasive operation:Use appropriate diamond or abrasive cutting tools rather than standard saw blades.

Support the ceramic rod along its length and close to the cut line to avoid bending.

Apply slow, steady feed without impact or sudden force changes.

Control heat and dust

Excess heat and dust can damage the rod and the workspace:Use coolant or light lubrication if compatible with your process.

Avoid overheating the cut zone to reduce microcracks.

Collect dust and wear proper PPE (eye, lung and skin protection).

Dress and inspect the cut end

After cutting, lightly deburr and dress the end to remove loose chips and sharp edges, especially if the rod is used as a guide, support or sealing surface. Inspect for cracks or chips before installation.Ask for engineering advice for critical parts

For critical guides, standoffs, furnace fixtures or high-temperature supports, share your drawing and target length with the ceramic rod supplier. They can confirm whether in-house cutting is acceptable or if factory cutting and finishing will be more reliable.

Yes. ADCERAX is a ceramic rod manufacturer supplying precision ceramic rods for sale in both stock and custom forms.

Stock precision rods – Selected diameters and lengths with ground finishes for guides, standoffs and fixtures.

Custom precision rods – Drawing-based grinding of diameter, length and straightness, with chamfers or special ends if required.

Material options – Alumina, zirconia, silicon nitride, silicon carbide and machinable ceramics to match your temperature, wear and insulation needs.

Share your material, diameter, length, tolerance and application, and we will recommend a suitable precision ceramic rod solution.

Alumina and zirconia are both engineering ceramics, but they behave quite differently in service:

Material behaviour

Alumina ceramic rods have high hardness, good wear resistance, strong electrical insulation and stable performance at high temperature.

Zirconia ceramic rods are much tougher, with higher fracture toughness and bending strength, so they tolerate impact and edge loading better than most ceramics.

Thermal and mechanical performance

Alumina handles high continuous temperatures well but is more sensitive to thermal shock and concentrated bending loads.

Zirconia works well in moderate-to-high temperatures with better resistance to chipping, cracking and cyclic mechanical stress, but its maximum working temperature is generally lower than high-purity alumina.

Cost and typical applications

Alumina rods are usually more cost-effective and are chosen for general high-temperature insulation, supports, guides and standoffs.

Zirconia rods are used where parts are small, highly stressed or require precise guidance and wear resistance, such as alignment pins, valve components and mechanical locating elements.

In practice, alumina ceramic rods are preferred for cost-efficient high-temperature insulation and structural supports, while zirconia ceramic rods are chosen for high-load, high-wear or impact-prone positions where toughness is more critical than maximum temperature.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

info@adcerax.com

Telephone: +(86) 0731-74427743

WhatsApp: +(86) 19311583352

Within 24 hours

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.