Advanced Silicon Carbide Plate for Furnace, Chemical & Power Systems by ADCERAX®

Silicon carbide ceramic plate technology enables stable thermal performance, long service life, and dimensional consistency across high-demand industrial processes.

The SiC Plates support precise thermal transfer, corrosion resistance, and repeatable performance for advanced manufacturing systems.

For engineering projects requiring consultation or custom evaluation, contact ADCERAX® for dedicated technical support.

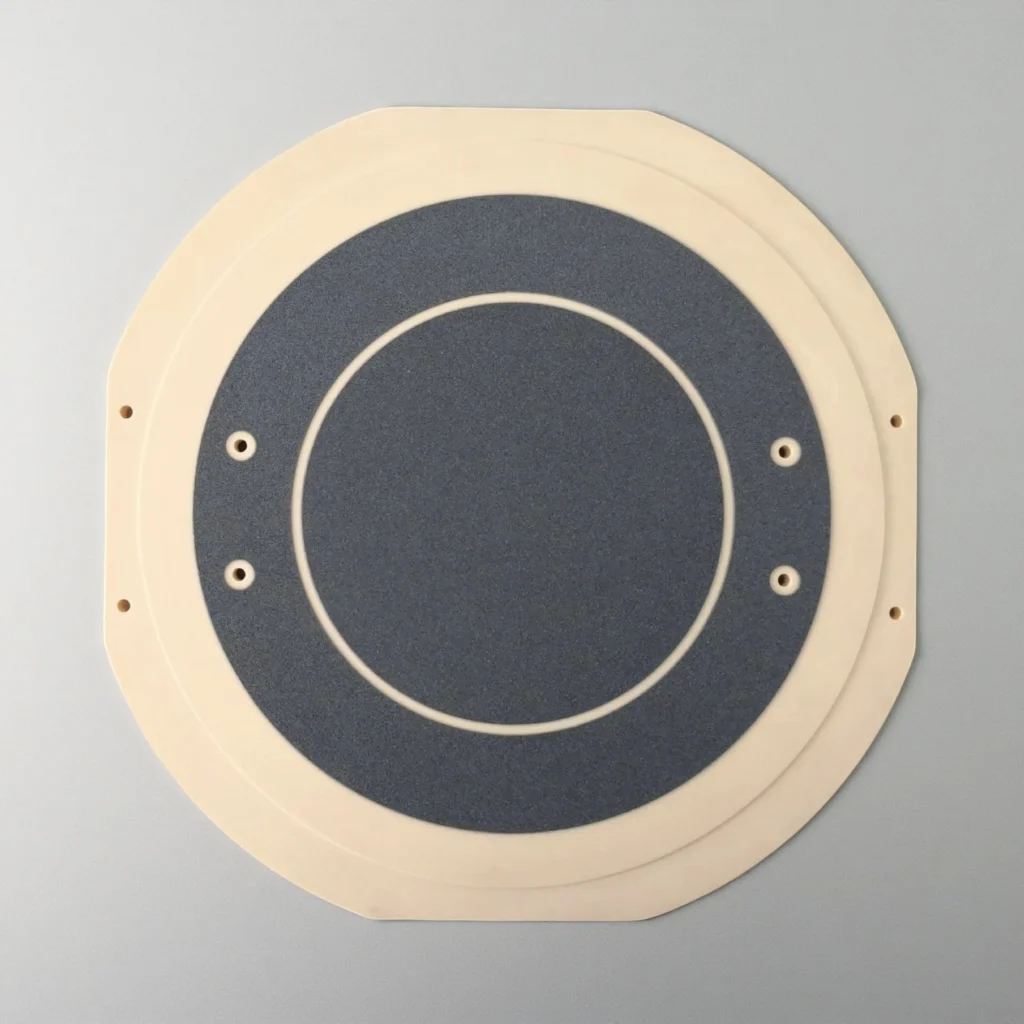

0.10 mm

Flatness Control

What Is a Silicon Carbide Plate?

A Silicon Carbide Plate is a flat structural or functional ceramic component designed to operate in extreme thermal, mechanical, and chemical environments. A silicon carbide ceramic plate maintains dimensional stability at elevated temperatures and resists deformation caused by heat cycling or corrosive atmospheres.

A SiC plate is produced from recrystallized SiC or reaction-bonded SiC to provide enhanced thermal conductivity, low thermal expansion, and long service lifetime. This material enables stable support, reliable thermal transfer, and contamination-free performance in demanding industrial systems.

Technical Specification of ADCERAX® Silicon Carbide Plate

Reliable engineering design requires consistent material parameters for sizing, thermal estimation, and structural evaluation. The values below represent typical performance ranges used by furnace designers, chemical-process engineers, and power-electronics manufacturers.

| Property | Typical Engineering Specification |

|---|---|

| Material Type | RBSiC (Reaction-Bonded SiC) / SSiC (Sintered SiC) |

| Density | 2.95–3.10 g/cm³ |

| Maximum Operating Temp. | 1300–1500°C (atmosphere-dependent) |

| Thermal Conductivity | Up to 200 W/m·K |

| Thermal Expansion Coefficient | <4.5×10⁻⁶/K |

| Flexural Strength | >300 MPa |

| Compressive Strength | >2000 MPa |

| Porosity | Closed porosity or controlled micro-porosity |

| Corrosion Resistance | High resistance to acids, alkalis, salts, gases |

Key Material Properties of ADCERAX® Silicon Carbide Plate

SiC plates deliver a balanced combination of thermal endurance, chemical resistance, and mechanical strength suited for large-scale industrial operations.

Their microstructural stability supports long-cycle manufacturing and predictable performance across repeated thermal, mechanical, and corrosive exposures.

Chemical Stability

A high level of chemical resistance is delivered through the inert microstructure of SiC plates.

-

Acid resistance maintained up to pH 1 exposure:

Withstands aggressive acid contact during extended cycles. -

Alkali stability verified above pH 13 conditions:

Maintains mass integrity under strong alkaline environments. -

Oxidation rate below 0.02 mg/cm²·h at 1000°C:

Surface condition preserved during high-temperature oxidation.

Thermal Performance

A stable thermal response is achieved due to the controlled lattice expansion of SiC plates.

-

Thermal conductivity reaches 180–200 W/m·K:

Heat distribution stays uniform under furnace cycling. -

Expansion coefficient remains below 4.5×10⁻⁶/K:

Dimensional distortion minimized during rapid heating. -

Continuous operation maintained at 1300–1500°C:

Plate structure remains stable in prolonged exposure.

Mechanical Strength

A high mechanical threshold is demonstrated by the dense crystalline network in sic silicon carbide plate products.

-

Flexural strength typically exceeds 300 MPa:

Reliable bending resistance under repetitive load cycles. -

Compressive strength reaches over 2000 MPa:

Structural integrity retained in heavy industrial loading. -

Wear rate falls below 0.1 mm³/1000 cycles:

Material loss minimized during abrasive impact events.

Dimensional Stability

A consistent geometric profile is maintained throughout thermal and mechanical cycling of silicon carbide plates.

-

Flatness deviation controlled within 0.05–0.10 mm:

Surface alignment preserved for precision assembly. -

Thickness tolerance held within ±0.1–0.2 mm:

Dimensional variation reduced across batch production. -

Warpage stays under 0.15 mm after 20 cycles:

Shape integrity sustained through repeated furnace runs.

ADCERAX® Silicon Carbide Plate Product Series

Vacuum holding uniformity is achieved through a controlled porous SiC microstructure.

- Even suction distribution across surface.

- Flatness variation below 0.05 mm.

- Pore uniformity maintained under 1000°C.

Thermal uniformity is supported through multi-pocket architecture and high SiC conductivity.

- Temperature deviation under ±2°C.

- Conductivity reaches 200 W/m·K.

- Pocket alignment ensures stable reactions.

High-temperature load capacity is sustained through dense SiC microstructural integrity.

- Flexural strength above 300 MPa.

- Operation supported to 1500°C.

- Thickness stability enhances furnace runs.

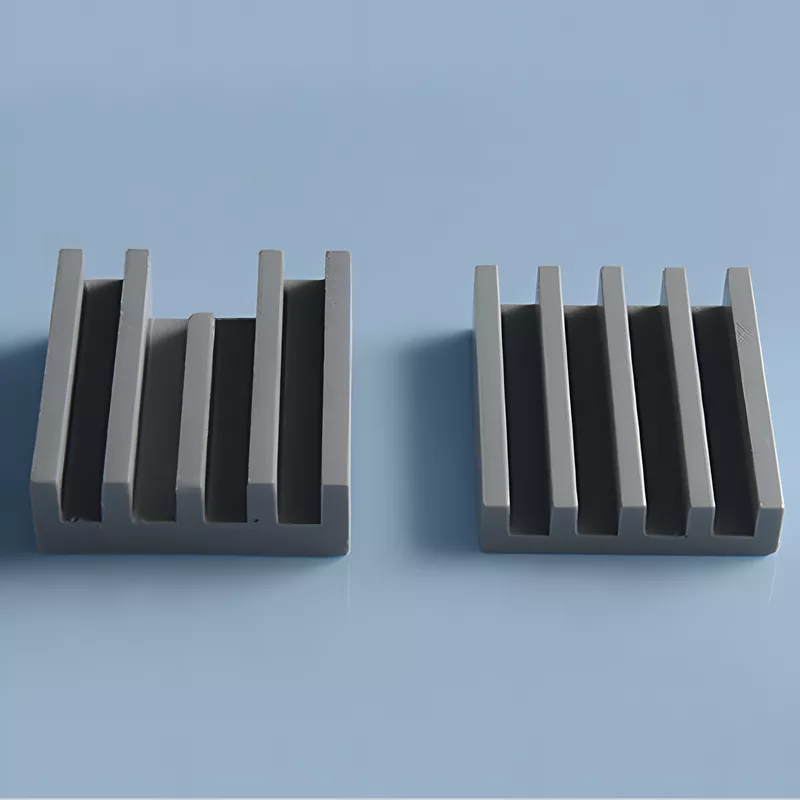

Heat dissipation efficiency is provided through advanced SiC conduction properties.

- Conductivity maintained at 180 W/m·K.

- Expansion coefficient below 4.5×10⁻⁶/K.

- Fin geometry increases cooling efficiency.

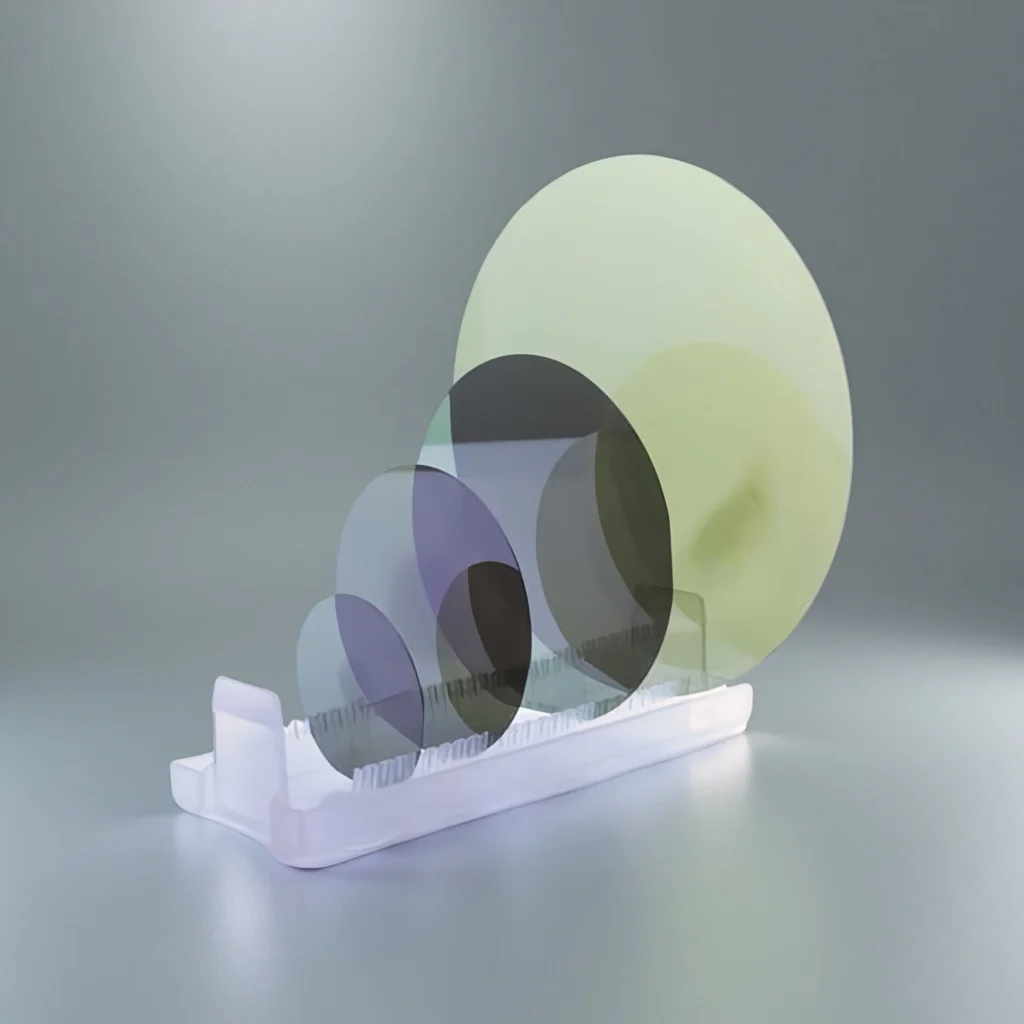

Wide-bandgap behavior is ensured through high-purity 4H/6H SiC substrates.

- Breakdown field exceeds 3 MV/cm.

- TTV variation under 5 μm.

- High lattice stability supports processing.

Crystalline reliability is maintained through controlled PVT growth and precision finishing.

- Resistivity customizable to 10 kΩ·cm.

- Warpage controlled below 40 μm.

- Semi-insulating grades enhance RF isolation.

Need Technical Assistance Choosing the Right Silicon Carbide SiC Plate?

Comprehensive evaluation support is available to clarify performance requirements, operating conditions, and compatibility factors for Silicon Carbide Plate integration in industrial equipment.

Application-specific guidance enables accurate selection for furnace platforms, chemical reactors, semiconductor tooling, and power-electronics systems.

Industrial Applications of ADCERAX® Silicon Carbide Plate

The usage of SiC Plate components spans multiple high-demand industrial sectors where temperature, corrosion, load, and dimensional precision define operational limits.

High-Temperature Furnaces and Sintering Systems

Thermal and mechanical reliability is demonstrated as silicon carbide plates are subjected to repeated high-temperature firing cycles.

- 1300–1500°C operation supports sintering of ceramics, metal powders, and battery materials, ensuring process repeatability in multi-zone kilns.

- Thickness stability within ±0.2 mm reduces product warpage and mitigates furnace downtime caused by plate deformation during 300+ cycles.

- Flexural strength above 300 MPa allows silicon carbide ceramic plates to sustain loading of trays, setter plates, and multi-layer components.

Chemical-Process Equipment and Corrosion-Intensive Systems

Corrosion resistance and surface stability are maintained when silicon carbide plate components encounter aggressive chemical streams.

- Resistance beyond pH 1–13 prevents material loss in chemical reactors and slurry systems handling acids, alkalis, and chloride-rich media.

- Oxidation rates under 0.02 mg/cm²·h at 1000°C help maintain long service intervals in high-temperature chemical towers.

- Wear rates below 0.1 mm³/1000 cycles extend lining life in pipelines, chutes, and mineral-processing vessels, reducing annual maintenance events.

Power-Electronics Cooling and Thermal-Management Platforms

Thermal conductivity and dimensional consistency are utilized to stabilize heat dissipation in high-density power-conversion assemblies.

- Conductivity reaching 180–200 W/m·K lowers device junction temperature by 10–18°C in inverter and converter systems using silicon carbide ceramic plates.

- Thermal expansion below 4.5×10⁻⁶/K maintains reliable bonding with IGBT and SiC MOSFET module bases during 1000+ heating cycles.

- Warpage under 0.15 mm preserves interface flatness, improving thermal-interface resistance and sustaining long-term device reliability.

Semiconductor Processing and Wafer-Handling Operations

Flatness precision and micro-porous uniformity are applied to stabilize wafer alignment and thermal distribution during sensitive semiconductor steps.

- Surface flatness below 0.05 mm on sic silicon carbide ceramic plate vacuum chucks improves CMP uniformity and dicing edge quality.

- Multi-pocket susceptors with ±2°C temperature uniformity support MOCVD, CVD, and RTP processes requiring strict thermal distribution across wafers.

- Wafer substrates exhibiting TTV <5 μm enable predictable lithography results, reducing yield loss across semiconductor pilot lines.

One-Stop Engineering & Supply Capability by ADCERAX®

Integrated Support for Custom SiC Plate Requirements

A complete service chain is established to help industrial users evaluate, engineer, validate, and deploy Silicon Carbide Plate solutions with predictable outcome and reduced procurement uncertainty.

This unified workflow resolves the common risks faced by global buyers, including tolerance mismatch, unstable lead time, and limited engineering collaboration in complex ceramic components.

-

Engineering Design & Application Mapping:

Comprehensive Application Modeling: Performance requirements and operating stresses are converted into manufacturable SiC plate geometries supporting predictable industrial deployment. -

Precision Shaping & Dimensional Stabilization:

Controlled Geometric Processing: CNC routing and calibrated sintering maintain critical tolerances needed for stable Silicon Carbide SiC Plate functionality across repeated thermal cycles. -

Performance Testing & Traceability Assurance:

Integrated Reliability Verification: Mechanical, thermal, and chemical properties are validated with full documentation to ensure consistent performance under harsh industrial conditions. -

Export Packaging, Delivery Control & Global Fulfillment:

Protected International Logistics: Reinforced packaging and shipment validation steps preserve component integrity throughout long-distance global delivery routes.

Enhanced Manufacturing Strength for SiC Plate Production

The production infrastructure supporting SiC Plate manufacturing integrates high-temperature sintering furnaces, multi-axis machining centers, professional metrology equipment, and standardized global shipping protocols.

| Manufacturing Capabilities Overview | |||

|---|---|---|---|

| Capability Item | Technical Specification / Performance | Engineering Value | |

| Large-Format SiC Sintering Capacity | 1800–2200°C controlled kilns (RBSiC / SSiC) | Supports stable densification for oversized SiC plates | |

| Sintering Shrinkage Control | ±0.25% lot-to-lot variation | Prevents warpage and improves assembly interchangeability | |

| CNC Machining Accuracy | Thickness tolerance ±0.05 mm; Flatness <0.10 mm | Satisfies semiconductor and high-precision furnace platforms | |

| Metrology Instruments | CMM + optical interferometer + ultrasonic densitometer | Guarantees high-precision validation of critical dimensions | |

| High-Temperature Cycling Test | 300–800 cycle validation at 1300–1500°C | Ensures durability for long-term furnace operation | |

customized silicon carbide plates supplier

We specialize in customizing silicon carbide plates with special sizes, tight tolerances, and complex features. OEM and small-batch support available.

Customization Options

Extra-large / Extra-small diameters, non-standard thicknesses, and ultra-long / ultra-short lengths.

Provide higher - level dimensional accuracy and concentricity control than the standard.

Flanges, steps, threads, drilling holes, grooves, etc.

Adjust the material according to the application requirements.

Polish and grind the surface to achieve a specific surface roughness.

Customization Process

Send us your drawing, CAD file, or physical sample with material grade, dimensions, tolerances, and quantity. Our engineers will evaluate the design and provide a detailed quotation with lead time and pricing.

Once the quote is approved, we proceed with sample prototyping (1–50 pcs) if needed, for testing and validation.

After sample approval or direct confirmation, we begin batch manufacturing using CNC machining, sintering, and polishing. All parts undergo dimensional checks, material purity testing, and surface finish inspection.

Finished products are securely packed and shipped via DHL/FedEx/UPS or your preferred method. We support global delivery with full documentation.

Technical FAQs on Silicon Carbide SiC Plate Performance and Engineering Use

A SiC Plate typically operates reliably between 1300–1500°C in continuous thermal cycling. Its high bending strength and low thermal expansion reduce crack initiation under rapid heat-up rates. At temperatures approaching the upper limit, microstructural stability prevents deformation and preserves load-bearing capability. This stability makes the material suitable for kilns, chemical reactors, and high-flux thermal modules.

A polished SiC Plate provides low surface roughness that reduces particle shedding and local friction during precision loading. This uniform finish contributes to improved flatness control, which is critical in wafer handling, thermal spreading, and vacuum-chuck contact. The enhanced smoothness minimizes micro-scratches, supporting higher yield in semiconductor-adjacent or optical processes.

A recrystallized Silicon Carbide SiC Plate features high porosity and excellent permeability that reduce internal thermal gradients. This structure improves shock resistance when the furnace cycles frequently between ambient and 1500°C. The material’s self-bonded grains maintain integrity without additives, preventing contamination of ceramic or powder-metallurgy parts during firing.

A sintered Silicon Carbide Plate provides extremely low open porosity, which minimizes chemical penetration in acidic or alkaline environments. The dense SSiC matrix delivers high abrasion resistance when exposed to slurry, abrasive powders, or metal particulates. This material grade maintains strength over prolonged exposure, reducing unplanned shutdowns in chemical, metallurgical, or material-handling systems.

A SiC Plate requires diamond-tool machining under controlled feed rates to prevent crack propagation. Coolant-assisted grinding maintains thermal stability along the cut zone, avoiding local overheating. Multi-axis CNC finishing ensures edge integrity to meet flatness, parallelism, and dimensional consistency for high-precision assemblies.

A SiC Plate maintains flatness due to low thermal expansion and stable grain bonding during rapid cycling. This behavior limits bowing and warping that commonly occur in alumina or cordierite alternatives. Reliable flatness supports stable loading conditions in kilns, heat-treatment lines, and high-temperature conveyors.

The extremely hard SiC lattice prevents abrasive erosion even under high-velocity slurry or particulate impacts. Its chemical inertness avoids surface thinning caused by acids, alkalis, or hot gases. This stability prolongs equipment life and reduces replacement frequency in reactors, mixers, or mineral-processing systems.

A Silicon Carbide Plate offers high thermal conductivity that equalizes temperature distribution across power modules. This reduces peak junction temperatures and prevents localized overheating. Its rigidity maintains stable contact pressure, enabling reliable long-term thermal management in EV inverters and industrial drive platforms.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.

Partner with ADCERAX for Silicon Carbide Plate

Looking for a reliable silicon carbide plates supplier? Let us help you with your next project.

info@adcerax.com

Tel.:

+(86) 0731-74427743

WhatsApp:

+(86)19311583352

Within 24 hours