High-performance engineering systems often fail at the material–component interface; therefore, advanced ceramics increasingly define reliability limits in real industrial equipment.

Zirconia ceramic occupies a unique position among advanced ceramics not merely because of intrinsic properties, but because those properties enable specific functional ceramic components used across structural, thermal, electrical, biomedical, and energy systems.

Before examining application-specific behavior, the underlying material mechanisms that enable zirconia ceramic uses must first be established, because these foundations explain why zirconia ceramic can be shaped into load-bearing, insulating, sensing, and bio-compatible components operating under incompatible conditions.

Material Foundations of Zirconia Ceramic

Zirconia ceramic derives its engineering relevance from crystallographic behavior and microstructural control; therefore, only a concise foundation is necessary to understand how specific zirconia ceramic components function in practice.

-

Crystal polymorphism and phase behavior

Zirconium oxide ceramic exists in monoclinic, tetragonal, and cubic phases. The tetragonal-to-monoclinic phase transformation involves a 3–5% volumetric expansion, which becomes mechanically useful once constrained inside a ceramic body. -

Transformation toughening mechanism

Through transformation toughening1, crack growth is locally suppressed, allowing zirconia ceramic components to function reliably as structural parts rather than brittle liners. -

Stabilized ZrO₂ ceramic systems

By adding stabilizers such as yttria or magnesia, zirconia ceramic maintains a metastable structure at room temperature. In practical terms, this stabilization enables zirconia ceramic to be manufactured into precision components with predictable service behavior.

In summary, phase control and stabilization establish the performance envelope of zirconia ceramic; therefore, the following sections focus on what zirconia ceramic is actually made into and where those parts are used.

Load Bearing Structures Enabled by Zirconia Ceramic

In load-dominated engineering systems, failure typically originates from crack propagation within structural parts; therefore, zirconia ceramic uses are most visible in mechanically loaded ceramic components replacing metals or weaker ceramics.

Stress tolerance in static and cyclic loading conditions

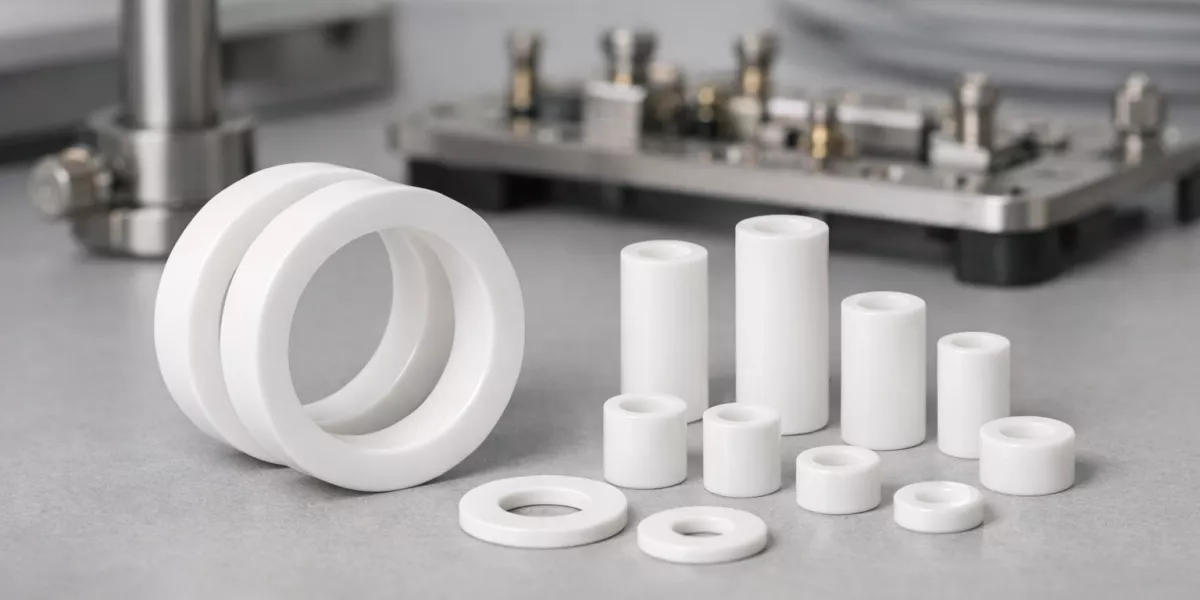

Zirconia ceramic is widely manufactured into ceramic shafts, support rods, positioning pins, bushings, and bearing sleeves that operate under compressive and bending loads. These components commonly function in fixtures, automated equipment, and mechanical assemblies where elastic deformation must remain minimal.

In cyclic environments, zirconia ceramic guide pins and locating rods maintain alignment over millions of cycles due to transformation toughening. As a result, these parts retain geometry where metallic pins experience wear-induced drift. This application focus explains zirconia ceramic uses in repetitive mechanical positioning rather than merely high-strength demonstration parts.

Under such conditions, structural reliability depends on crack arrest rather than ultimate strength. Therefore, zirconia ceramic components serve as load-bearing elements in precision machinery rather than sacrificial liners.

ZrO₂ ceramic behavior at wear-driven contact interfaces

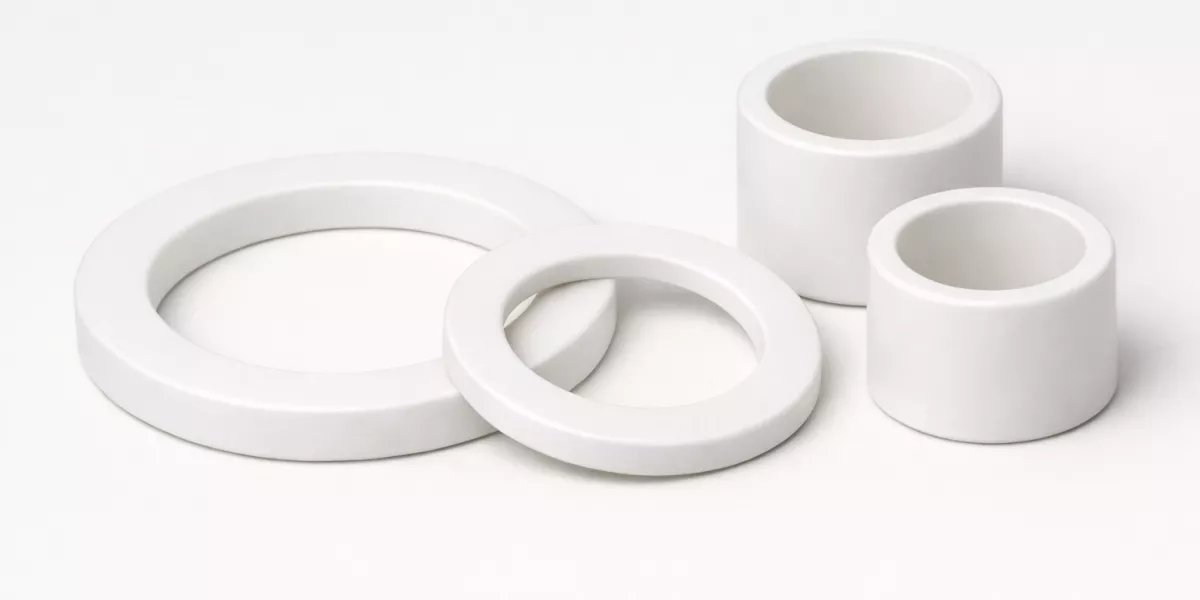

At wear interfaces, zirconia ceramic is commonly used to produce ceramic bearing balls, valve seats, wear rings, rollers, and sliding guides. These components operate in dry or marginally lubricated environments where metallic wear debris would contaminate systems.

Operational assemblies employing zirconium oxide ceramic rollers or bushings show stable contact geometry with minimal debris generation. Consequently, zirconia ceramic uses concentrate on clean mechanical systems, including laboratory automation, measuring equipment, and fluid handling devices where wear particles directly degrade performance.

Nevertheless, counterface pairing remains critical. Therefore, zirconia ceramic wear components are typically matched with polished ceramics or hardened alloys to maintain predictable tribological behavior.

Long-term dimensional integrity under mechanical load

Zirconia ceramic components such as support spacers, structural sleeves, and load-distribution rings are specified where dimensional stability governs equipment calibration. These parts resist creep and plastic deformation under sustained load.

In practical equipment layouts, zirconia ceramic spacers preserve alignment accuracy over extended service intervals, reducing recalibration frequency. This stability under sustained mechanical stress differentiates zirconia ceramic uses from polymeric or metallic load supports.

As a result, zirconia ceramic load-bearing parts are frequently integrated into equipment where downtime directly impacts productivity.

Summary Table: Load-Bearing Zirconia Ceramic Components and Functions

| Zirconia Ceramic Component | Primary Function |

|---|---|

| Ceramic shafts and rods | Structural support and alignment |

| Bearing balls and rollers | Low-wear motion control |

| Bushings and sleeves | Load distribution and wear isolation |

| Positioning pins | Precision location under cyclic load |

| Structural rings and spacers | Dimensional stability under compression |

Dimensional Stability Applications Using ZrO₂ Ceramic

Precision systems fail gradually through accumulated geometric error; therefore, zirconia ceramic uses concentrate on components that define reference geometry rather than primary load paths.

Elastic modulus and micron-scale positioning accuracy

Zirconia ceramic is routinely manufactured into gauge pins, reference blocks, alignment dowels, and precision spacers. These parts serve as physical datums in metrology fixtures, inspection systems, and automated positioning equipment.

In practical assemblies, zirconia ceramic reference pins maintain repeatable positioning after repeated engagement, unlike metallic pins that undergo micro-settling. This application-driven reliability explains zirconia ceramic uses in dimensional control hardware rather than decorative precision parts.

Accordingly, stiffness uniformity becomes more valuable than peak strength in these applications.

Thermal expansion consistency in precision environments

Zirconium oxide ceramic components such as metrology frames, sensor mounts, and precision supports are used where thermal gradients cannot be fully eliminated. Their predictable thermal expansion minimizes relative displacement between components.

In temperature-variable environments, zirconia ceramic mounts preserve sensor alignment and measurement accuracy. Such functional deployment reinforces zirconia ceramic uses in precision systems rather than high-temperature structural frames.

However, consistent microstructure remains essential. Therefore, processing control directly impacts dimensional outcomes.

Surface finish limits and repeatable contact behavior

Zirconia ceramic is widely applied in contact surfaces for precision fixtures, including stop faces, reference pads, and alignment interfaces. These surfaces maintain stable roughness after repeated contact.

Operational data from fixture systems show zirconia ceramic contact pads retain reference accuracy after thousands of cycles. This repeatability further grounds zirconia ceramic uses in real precision tooling rather than theoretical material advantages.

Summary Table: Dimensional Control Zirconia Ceramic Components

| Zirconia Ceramic Component | Precision Role |

|---|---|

| Gauge pins and dowels | Reference positioning |

| Alignment blocks | Geometry definition |

| Sensor mounts | Thermal drift control |

| Reference pads | Repeatable contact surfaces |

| Precision spacers | Fixed-distance control |

High Temperature Structures Based on Zirconium Oxide Ceramic

At elevated temperatures, many ceramics lose structural reliability; therefore, zirconia ceramic uses focus on components that must retain shape and load capacity under heat.

Strength retention at elevated operating temperatures

Zirconium oxide ceramic is shaped into furnace support rods, high-temperature spacers, insulation supports, and structural tubes that operate inside heating systems. These components retain mechanical function where polymeric or metallic parts degrade.

In continuous-operation furnaces, zirconia ceramic supports maintain geometry under sustained heat exposure. This application-driven performance explains zirconia ceramic uses in internal furnace structures rather than external housings.

Resistance to rapid heating and quenching cycles

Zirconia ceramic support pins, fixtures, and holders are commonly used in systems experiencing frequent thermal cycling. These parts survive repeated startup and shutdown events without cracking.

Consequently, zirconia ceramic becomes suitable for components that experience rapid temperature transitions rather than steady-state exposure alone.

Performance boundaries relative to alumina and silicon carbide

Compared with alumina fixtures and silicon carbide supports, zirconia ceramic occupies an intermediate role. It is selected when fracture resistance and insulation matter more than extreme heat dissipation.

Summary Table: High-Temperature Zirconia Ceramic Components

| Zirconia Ceramic Component | High-Temperature Function |

|---|---|

| Structural tubes | Thermal isolation and support |

| Furnace rods | Load-bearing at elevated temperature |

| Support spacers | Dimensional stability under heat |

| Thermal fixtures | Repeated thermal cycling tolerance |

Heat Management and Insulation with Zirconia Ceramic Systems

Heat flow control frequently determines whether an engineering system maintains efficiency or experiences premature degradation; therefore, zirconia ceramic uses increasingly focus on thermal control components that simultaneously restrict heat transfer and preserve mechanical integrity. Moreover, unlike fibrous or polymer-based insulators, zirconium oxide ceramic components remain dimensionally stable under sustained thermal gradients, which enables predictable long-term heat management.

Low thermal conductivity mechanisms in stabilized ZrO₂

Zirconia ceramic is widely fabricated into insulating tubes, thermal spacers, ceramic barriers, and rigid heat shields that function directly within hot zones rather than at peripheral insulation layers. These components are typically positioned between heat sources and load-bearing or sensitive assemblies, where spatial constraints limit the use of thick insulation stacks.

At the microstructural level, stabilized ZrO₂ contains oxygen vacancies that disrupt phonon transport. As a result, bulk thermal conductivity remains low, typically 2.0–2.5 W/m·K at room temperature and below 3.0 W/m·K at 1000 °C, even after prolonged exposure. Consequently, zirconia ceramic insulation components reduce conductive heat flux without sacrificing structural rigidity. This mechanism explains why zirconia ceramic uses appear in compact thermal isolation roles where space efficiency is critical.

In practical equipment layouts, insulating zirconia ceramic tubes and spacers allow designers to localize heat barriers precisely, rather than relying on generalized enclosure insulation. Therefore, thermal control becomes a component-level function rather than a system-level workaround.

Bulk insulation versus layered thermal configurations

Zirconia ceramic supports both monolithic insulation parts and layered thermal barrier architectures, depending on system design priorities. Bulk components such as ceramic blocks, rings, and thick-walled tubes provide uniform thermal resistance across thicknesses of 5–20 mm, eliminating interface losses and delamination risks.

Conversely, zirconium oxide ceramic coatings applied at 200–500 µm thickness act as thermal barrier layers on metallic substrates, reducing surface temperatures by 120–180 °C under steady heat flux. These layered configurations allow metals to retain mechanical strength while zirconia ceramic limits heat penetration. Accordingly, zirconia ceramic uses extend across both standalone insulation components and composite heat management systems.

However, layered systems introduce thermal expansion mismatch concerns. Therefore, bulk zirconia ceramic insulation components are often preferred where long-term thermal cycling reliability outweighs weight or thickness constraints.

Stability under prolonged thermal cycling

Thermal insulation performance deteriorates when materials sinter, crack, or densify under repeated heating. Zirconia ceramic insulation components resist such degradation due to phase stability below 1200 °C and robust grain boundary cohesion.

Long-duration cycling tests show that zirconia ceramic spacers and barriers exhibit less than 5% increase in thermal conductivity after 1000 cycles between ambient temperature and 900 °C. Consequently, insulation performance remains consistent throughout service life. This resistance to thermal fatigue further anchors zirconia ceramic uses in systems dominated by frequent startup–shutdown cycles rather than steady-state heating.

Nevertheless, exposure beyond stabilization limits may induce grain growth. Therefore, composition and service envelope definition remain essential during design.

Summary Table: Thermal Management Zirconia Ceramic Components

| Zirconia Ceramic Component | Thermal Role |

|---|---|

| Insulating tubes | Localized heat flow restriction |

| Thermal spacers | Temperature zone separation |

| Barrier coatings | Surface heat reduction |

| Insulation rings | Compact thermal isolation |

Electrical Insulation Functions of Zirconia Ceramic Materials

Electrical insulation failure often coincides with elevated temperature and mechanical stress; therefore, zirconia ceramic uses increasingly target insulation components that remain electrically stable under combined thermal and structural loads. Moreover, zirconium oxide ceramic provides predictable dielectric behavior where polymers degrade and metallic conductors compromise isolation.

Electrical resistivity under elevated temperature

Zirconia ceramic is commonly manufactured into electrical insulation tubes, standoffs, spacers, and isolating sleeves integrated directly into high-temperature electrical assemblies. These components isolate conductive elements while simultaneously supporting mechanical loads.

At ambient temperature, volume resistivity typically exceeds 10¹² Ω·cm, while at 800 °C resistivity remains within 10⁶–10⁷ Ω·cm. Consequently, insulation performance degrades gradually rather than collapsing abruptly. This predictable resistivity decay supports zirconia ceramic uses in electrical systems where controlled failure modes are essential for safety.

In operational environments where polymer insulators carbonize or soften, zirconia ceramic insulation components maintain electrical separation without deformation. Therefore, electrical reliability becomes independent of thermal exposure.

Dielectric behavior and signal integrity considerations

Beyond basic isolation, zirconium oxide ceramic is shaped into sensor housings, insulating substrates, and signal-support components that influence electromagnetic behavior. Typical relative dielectric constants of 20–30 enable stable capacitive characteristics across a wide temperature range.

Dielectric loss tangents remain below 0.01 at 1 MHz, even at elevated temperatures approaching 600 °C. As a result, signal distortion remains limited under thermal stress. Such dielectric consistency reinforces zirconia ceramic uses in sensing and monitoring systems operating near heat sources.

However, dielectric behavior depends on microstructural uniformity. Therefore, grain size control and impurity minimization remain critical during component fabrication.

Combined electrical and mechanical stress environments

Electrical insulation components often experience mechanical loading from assembly constraints or vibration. Zirconia ceramic load-bearing insulators and standoffs tolerate compressive stresses exceeding 1000 MPa without measurable loss of dielectric strength.

In combined-stress testing, zirconium oxide ceramic maintains dielectric breakdown strength above 8–10 kV/mm under sustained mechanical load. Consequently, insulation integrity remains intact even when components function structurally. This dual capability explains zirconia ceramic uses in electrically active systems where mechanical and electrical roles cannot be separated.

Thus, zirconia ceramic enables integrated designs that reduce part count and interface complexity.

Summary Table: Electrical Zirconia Ceramic Components

| Zirconia Ceramic Component | Electrical Function |

|---|---|

| Insulation tubes | High-temperature electrical isolation |

| Standoffs and spacers | Mechanical and dielectric separation |

| Sensor housings | Signal stability near heat |

| Insulating sleeves | Load-bearing dielectric support |

Chemical Durability of Zirconium Oxide Ceramic in Reactive Media

Chemical attack often proceeds invisibly until component failure occurs; therefore, zirconia ceramic uses emphasize parts directly exposed to corrosive or reactive environments. Moreover, zirconium oxide ceramic maintains structural and surface stability where metals corrode and polymers swell or dissolve.

Performance in acidic and alkaline exposure

Zirconium oxide ceramic is routinely formed into valve seats, pump liners, flow channels, nozzles, and reaction tubes operating in acidic or alkaline media. These components function across a broad pH range from 1 to 13 without measurable chemical degradation.

Mass loss during immersion testing typically remains below 0.01% after 1000 hours, even at elevated temperature. Consequently, zirconia ceramic components retain geometry and sealing performance under continuous exposure. This durability directly explains zirconia ceramic uses in chemically aggressive process equipment.

In such systems, chemical resistance serves not only to prevent failure but also to preserve dimensional tolerance. Therefore, zirconia ceramic enables longer service intervals and predictable maintenance schedules.

Material purity and contamination control

Chemical durability also includes resistance to contamination and leaching. High-purity zirconia ceramic components generally contain impurity levels below 0.1 wt%, limiting ion release into surrounding media.

Measured leaching rates typically remain below 1 ppm in neutral and mildly acidic solutions. As a result, process fluids maintain chemical integrity. This low contamination behavior reinforces zirconia ceramic uses in systems where product purity or downstream reactions are sensitive to trace impurities.

However, impurity segregation at grain boundaries may accelerate localized attack. Therefore, consistent processing remains critical.

Long-term immersion and surface stability

Surface stability determines whether chemically exposed components retain function over time. Zirconia ceramic liners, sleeves, and contact surfaces resist hydrochemical attack, maintaining surface roughness variation within ±0.02 µm after extended immersion.

Accelerated aging tests at 80–90 °C for 2000 hours reveal no grain pull-out or microcracking. Consequently, sealing and flow characteristics remain unchanged. This sustained surface integrity further grounds zirconia ceramic uses in long-term chemical service rather than short-term resistance scenarios.

Summary Table: Chemically Exposed Zirconia Ceramic Components

| Zirconia Ceramic Component | Chemical Role |

|---|---|

| Valve seats | Corrosion-resistant sealing |

| Pump liners | Media isolation |

| Reaction tubes | Chemical containment |

| Contact surfaces | Long-term surface stability |

Biomedical Applications Involving Zirconia Ceramic Components

Biomedical systems impose strict biological and mechanical constraints; therefore, zirconia ceramic uses concentrate on implantable and human-contact components where inertness, strength, and long-term stability must coexist. Moreover, zirconium oxide ceramic maintains predictable behavior in physiological environments that degrade many metallic materials.

Biocompatibility and biological inertness

Zirconia ceramic is extensively manufactured into dental crowns, implant abutments, surgical spacers, and medical positioning components. These parts remain chemically inert in contact with bodily fluids and tissues.

In standardized biological evaluations, cell viability exceeds 95% after 72 hours, indicating negligible cytotoxicity. Furthermore, surface chemistry remains stable after 1000 hours in simulated body fluid. Such biological neutrality underpins zirconia ceramic uses in permanent or semi-permanent medical components.

Consequently, zirconia ceramic becomes suitable for long-term implantation rather than temporary tooling.

Load-bearing roles in medical systems

Beyond biocompatibility, medical components often experience repetitive physiological loading. Zirconium oxide ceramic dental structures and orthopedic components sustain cyclic stresses without crack initiation over 10 million cycles at representative load levels.

This fatigue endurance enables zirconia ceramic components to function reliably in load-bearing anatomical roles. Therefore, zirconia ceramic uses in biomedical systems extend beyond cosmetic restoration into structural load transfer.

Nevertheless, design must minimize tensile stress concentrations. Hence, geometric optimization remains critical.

Aging behavior in moist physiological environments

Hydrothermal aging presents a known challenge for zirconia ceramic. Stabilized formulations limit low-temperature degradation, restricting tetragonal-to-monoclinic transformation to below 2% volume fraction after 5000 hours at 37 °C.

Even under accelerated steam aging at 134 °C, transformation depth remains below 20 µm, preserving bulk properties. This controlled aging behavior supports zirconia ceramic uses in moist physiological environments requiring predictable long-term performance.

Summary Table: Biomedical Zirconia Ceramic Components

| Zirconia Ceramic Component | Medical Function |

|---|---|

| Dental crowns | Structural restoration |

| Implant abutments | Load transfer |

| Medical spacers | Positional stability |

| Surgical fixtures | Biocompatible support |

Energy and Electrochemical Systems Using ZrO₂ Ceramic

Energy conversion systems impose coupled thermal, chemical, and electrical stresses; therefore, zirconia ceramic uses emphasize functional components enabling electrochemical operation at elevated temperature. Moreover, ZrO₂ ceramic uniquely combines ionic conductivity with mechanical stability.

Oxygen ion conductivity and electrolyte behavior

Stabilized zirconia ceramic functions as solid oxide electrolyte plates, tubes, and membranes, enabling oxygen ion conductivity2. Ionic conductivity typically reaches 0.05–0.15 S/cm between 700–1000 °C.

These electrolyte components facilitate oxygen ion transport while maintaining gas separation. Such functional deployment anchors zirconia ceramic uses in electrochemical systems rather than purely structural roles.

Stability in high-temperature electrochemical operation

Zirconia ceramic electrolyte components remain phase-stable under continuous redox cycling. Testing demonstrates stable performance over 2000 thermal–electrochemical cycles without microcracking.

This durability enables reliable startup–shutdown operation. Therefore, zirconia ceramic supports energy systems where cycling dominates service conditions.

Structural versus functional deployment strategies

Zirconium oxide ceramic also serves as mechanical supports, spacers, and housings within energy assemblies. In integrated designs, electrolyte and support roles coexist within a single ceramic architecture.

This dual structural–functional capability expands zirconia ceramic uses across energy systems requiring material compatibility and reduced interface complexity.

Summary Table: Energy-System Zirconia Ceramic Components

| Zirconia Ceramic Component | Energy Function |

|---|---|

| Electrolyte plates | Oxygen ion transport |

| Electrolyte tubes | Electrochemical separation |

| Structural supports | Mechanical stability |

| Hybrid assemblies | Integrated functionality |

Optical and Functional Surfaces Derived from Zirconia Ceramic

Surface behavior increasingly defines component usability; therefore, zirconia ceramic uses also include surface-critical components where optical appearance and functional durability intersect.

For instance, zirconia ceramic is formed into polished plates, wear-resistant contact faces, and visually exposed structural parts requiring consistent surface quality. Controlled grain size below 0.5 µm enables partial translucency, supporting applications where glare reduction matters more than transparency.

Polished zirconium oxide ceramic surfaces achieve gloss values above 80 GU while retaining hardness exceeding 1200 HV. Consequently, wear does not rapidly degrade appearance. This convergence of surface durability and optical stability broadens zirconia ceramic uses into surface-sensitive engineering environments.

Summary Table: Surface-Oriented Zirconia Ceramic Components

| Zirconia Ceramic Component | Surface Function |

|---|---|

| Polished plates | Optical stability |

| Wear surfaces | Functional durability |

| Decorative–structural parts | Visual consistency |

Integrated View of Zirconia Ceramic Applications Across Industries

Zirconia ceramic uses converge on functional ceramic components, not abstract material superiority. Its adoption reflects compatibility with real operating constraints rather than isolated property optimization.

Conclusion

Zirconia ceramic enables specific functional ceramic components that operate reliably where structural, thermal, chemical, and electrical demands intersect.

For systems requiring durable ceramic components rather than material substitution alone, zirconia ceramic offers a mature and versatile solution.

FAQ

What types of components are commonly made from zirconia ceramic?

Zirconia ceramic is commonly manufactured into shafts, bearings, spacers, insulation tubes, valve seats, electrolytes, and biomedical components.

Why is zirconia ceramic chosen over metals in some applications?

Zirconia ceramic components maintain geometry, resist wear, and remain stable under heat and corrosion where metals degrade.

Can zirconia ceramic serve both structural and functional roles?

Yes. Zirconium oxide ceramic functions as both load-bearing parts and electrochemical components depending on design.

Where does zirconia ceramic offer the greatest advantage?

Zirconia ceramic excels in applications requiring toughness, insulation, and stability under combined stresses.

References: