Engineering-Grade Magnesia Stabilized Zirconia MSZ Ceramic for Extreme Stability by ADCERAX®

Magnesia Stabilized Zirconia (MSZ) Ceramic delivers exceptional thermal-shock durability and long-term dimensional stability under harsh multi-physics conditions.

Its MgO-stabilized lattice structure resists microcracking and maintains strength where conventional ceramics fail.

ADCERAX® supplies precision-engineered MSZ Zirconia components with fast lead time and no MOQ limitations.

withstands repeated 1400°C cycles

inert to acids alkalis solvents

maintains geometry under load

stable strength at high temperatures

What Defines Magnesia Stabilized Zirconia (MSZ) Ceramic as an Engineering Material

Magnesia Stabilized Zirconia (MSZ) Ceramic is a partially stabilized zirconia system engineered for thermal shock endurance, mechanical robustness, and high-temperature stability.

Its MgO-stabilized lattice structure minimizes phase transformation risks that commonly restrict the performance of traditional zirconia materials.

This unique material system supports long-duration operation in demanding industrial environments where both heat and corrosive media coexist.

compressive strength exceeding 1800 MPa in tests

stable to 1400°C thermal cycling

resistivity above 10^9 Ω·cm at 25°C

weight loss below 0.05% in acids

Material Properties and Engineering Performance of ADCERAX® MSZ Zirconia

Magnesia Stabilized Zirconia (MSZ) Ceramic demonstrates a property set optimized for high-temperature, corrosive, and mechanically demanding workloads.

Its stabilized lattice architecture allows consistent performance where conventional zirconia grades suffer from phase instability.

These material characteristics enable MSZ to serve reliably across thermal, mechanical, electrical, and chemical stress environments.

Thermal Properties of MSZ Zirconia Ceramic

| Thermal Property Category | Test Parameter | Typical MSZ Value | Test Method / Note |

|---|---|---|---|

| Thermal Stability | Maximum Working Temperature | 1400–1500°C | High-temperature holding test (4 h) |

| Thermal Stability | Thermal Expansion Coefficient | 9.5–10.5 × 10⁻⁶ K⁻¹ | Dilatometry (RT → 1200°C) |

| Thermal Shock Resistance | Crack-Initiation Threshold | 30–45% higher than YSZ | Quench test (ΔT > 600°C) |

| Thermal Shock Resistance | Thermal Gradient Withstanding Rate | Rapid heating 15–25°C/s | Furnace ramp test |

| High-Temperature Dimensional Stability | Creep Deformation Ratio | <0.12% at 1300°C / 2 h | Static load creep test |

Electrical Properties of MSZ Zirconia Ceramic

| Electrical Property Category | Test Parameter | Typical MSZ Value | Test Method / Note |

|---|---|---|---|

| Insulation | Volume Resistivity | >10⁹ Ω·cm | ASTM D257 |

| Dielectric Strength | Breakdown Voltage | 8–12 kV/mm | ASTM D149 |

| Dielectric Properties | Relative Permittivity (εr) | 25–32 | Impedance spectroscopy |

| Electrical Stability | Leakage Current at 500 V | <0.01 μA | High-voltage leakage test |

| Conductivity | Ionic Conductivity | Low (10⁻⁵–10⁻⁶ S/cm) | AC impedance measurement |

Chemical Properties of MSZ Zirconia Ceramic

| Chemical / Electrical Property Category | Test Parameter | Typical MSZ Value | Test Method / Note |

|---|---|---|---|

| Chemical Stability | Acid Corrosion Mass Loss | <0.05% | 24 h immersion in HCl / H₂SO₄ |

| Chemical Stability | Alkali Corrosion Mass Loss | <0.08% | 24 h immersion in NaOH |

| Corrosion Resistance | Molten Metal Interaction | No reaction / no wetting | Al / Cu molten contact test |

| Electrical Insulation | Volume Resistivity | >10⁹ Ω·cm | ASTM D257 |

| Dielectric Strength | Dielectric Breakdown Voltage | 8–12 kV/mm | ASTM D149 |

Mechanical Properties of MSZ Zirconia Ceramic

| Mechanical Property Category | Test Parameter | Typical MSZ Value | Test Method / Note |

|---|---|---|---|

| Strength | Compressive Strength | 1800–2000 MPa | ISO 14704 compression test |

| Strength | Flexural Strength | 190–220 MPa | 3-point bending test |

| Toughness | Fracture Toughness (KIC) | 2.5–4.0 MPa·m½ | Single-edge notched beam |

| Hardness | Vickers Hardness | 11–12 GPa | HV10 test |

| Wear Resistance | Dry Sliding Wear Rate | 40–60% lower than alumina | Pin-on-disc wear test |

Advanced MSZ Zirconia Components for High-Demand Industrial Systems

ADCERAX® offers Magnesia Stabilized Zirconia (MSZ) Ceramic performing across thermal, mechanical, and corrosive operating environments.

MSZ Tubes

Precision tubular geometry enabling stable thermal flow control.

- Supports high-temp gradient cycling

- Ensures thermal expansion behavior

- Maintains chemical inertness in pipelines

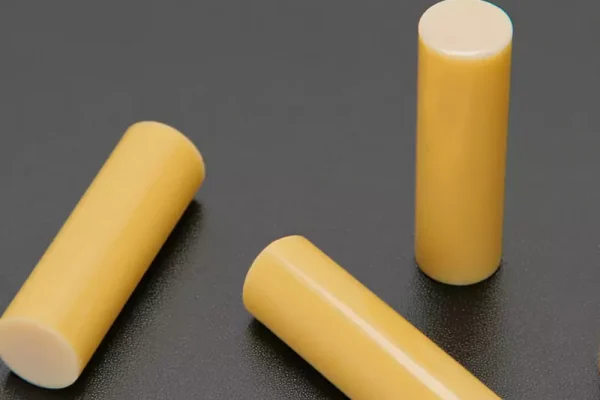

MSZ Rods

Dense structural rod optimized for repeated mechanical loading.

- High compressive strength reliability

- Reduced surface wear progression

- Dimensional stability under heat

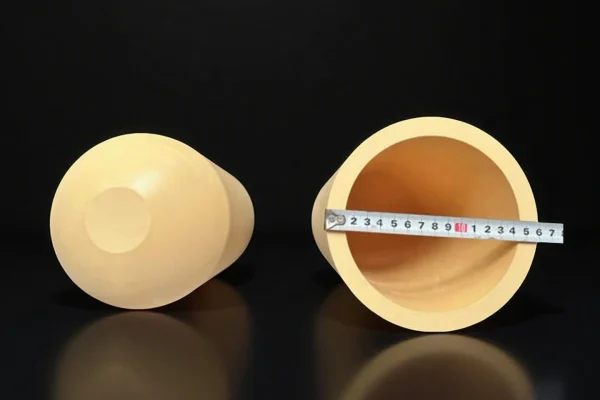

MSZ Crucibles

High-temperature cavity designed for corrosive melt processes.

- Avoids reaction with molten metals

- Withstands aggressive thermal cycling

- Controls contamination in hot zones

MSZ Ball Valves

Durable flow-control assembly for corrosive fluid operations.

- Resists surface abrasion in cycling flow

- Maintains sealing geometry under heat

- Offers extended service life uptime

MSZ Plate

Flat MSZ plate engineered for thermal and structural stability.

- Exhibits low creep at high temperature

- Maintains flatness during thermal loading

- Provides contamination-free surface use

MSZ Valves

Chemical-resistant valve body for aggressive industrial media.

- Preserves integrity in strong alkalis

- Supports long-cycle pressure handling

- Minimizes dimensional drift exposure

MSZ Gauge Blocks

Precision reference block offering stable dimensional accuracy.

- Provides micro-level thermal stability

- Maintains calibration over long cycles

- Resists wear from repeated handling

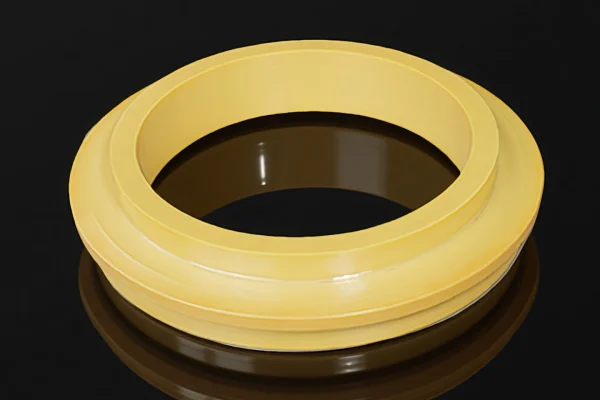

MSZ Rings

Structural ring geometry for load-bearing mechanical interfaces.

- Maintains form under cyclic pressure

- Exhibits consistent expansion behavior

- Provides stable abrasion resistance

MSZ Seal Ring

High-integrity sealing ring for corrosive and heated systems.

- Maintains sealing force under load

- Resists acid and alkali attack

- Controls wear in dynamic contact

MSZ Pin

Precision pin designed for repetitive positioning stability.

- Supports impact-resistant alignment cycles

- Offers strong anti-wear performance

- Retains geometry during heat exposure

MSZ Piston

High-strength piston optimized for high-frequency actuation.

- Provides low friction contact stabilization

- Maintains compression force consistency

- Supports high-temperature fluid systems

MSZ Sleeve

Protective insulating sleeve for thermo-mechanical isolation.

- High electrical insulation stability

- Corrosion in fluid pathways

- Dimensional reliability under heat

We maintain a ready stock of standard zirconia ceramic products, ensuring 24-hour dispatch for urgent requirements, enabling you to minimize downtime and maintain operational continuity.

Industrial Applications of ADCERAX® Magnesia Stabilized Zirconia Ceramic

Advanced Chemical Process Components for Corrosive Fluid Handling

MSZ components maintain dimensional and chemical stability under corrosive fluids and continuous pump cycling.

- Magnesia Stabilized Zirconia Ceramic Valve improving corrosive-media durability

- MSZ Ceramic Ball Valve resisting chloride-rich chemical streams

- Magnesia Stabilized Zirconia Ceramic Sleeve supporting long-cycle pump operation

Precision Metering Assemblies for High-Accuracy Dosing and Dispensing Systems

High-hardness MSZ Zirconia Ceramic surfaces maintain micro-level volumetric accuracy under repetitive reciprocating motion.

- Magnesia Stabilized Zirconia Ceramic Piston ensuring consistent micro-dispensing accuracy

- Magnesia Stabilized Zirconia Ceramic Pin stabilizing high-precision alignment points

- Magnesia Stabilized Zirconia Ceramic Sleeve reducing friction under metering loads

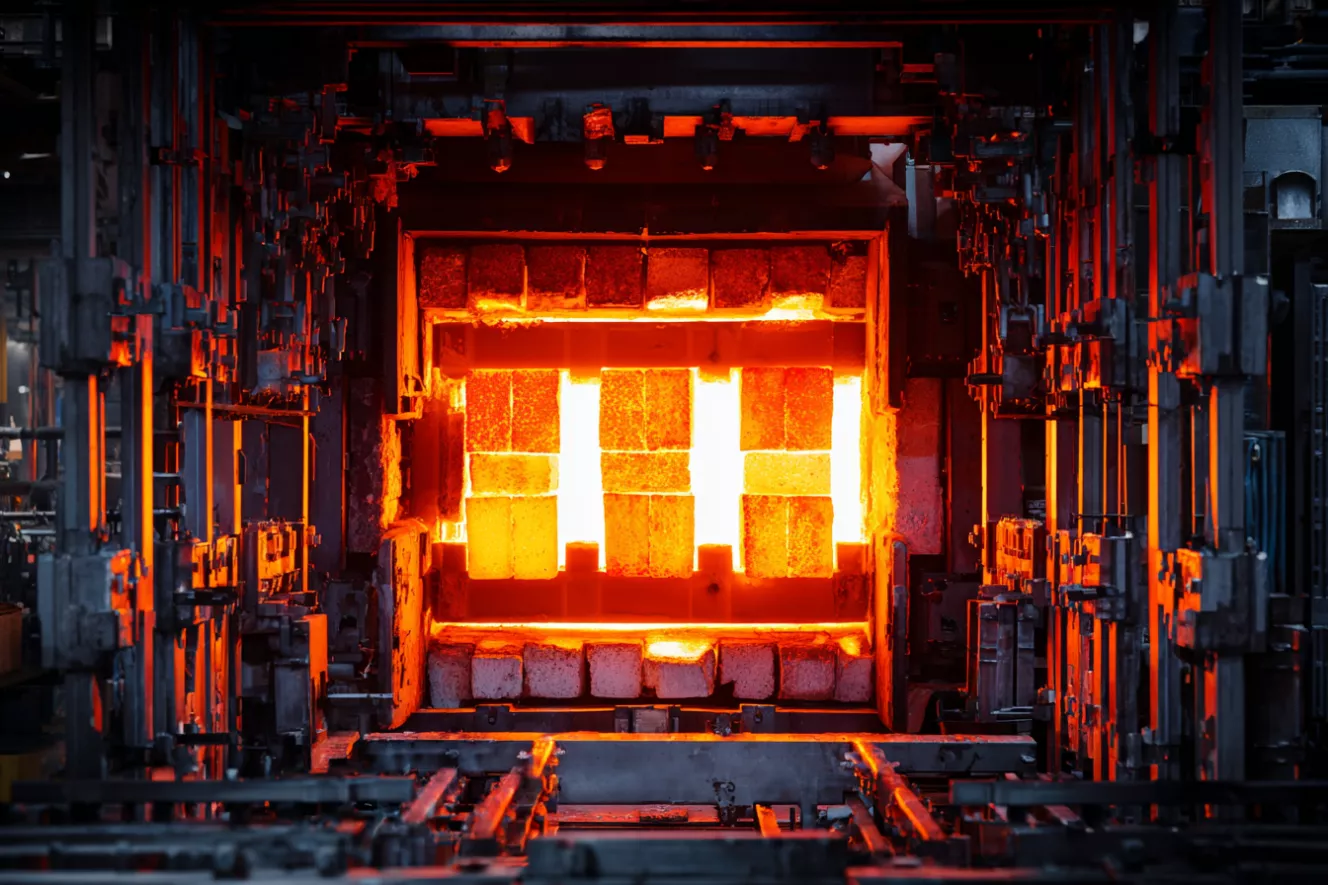

High-Temperature Metallurgical Fixtures for Thermal Cycling and Sintering Operations

MgO-ZrO₂ Ceramic maintains strength, thermal-shock tolerance, and contamination-free performance in elevated-temperature environments.

- Magnesia Stabilized Zirconia Crucible providing clean alloy melting conditions

- MSZ Ceramic Plate stabilizing heat-treatment support fixtures

- Magnesia Stabilized Zirconia Rod sustaining thermal-mechanical loading cycles

Dimensional Calibration Elements for Stable and Corrosion-Free Metrology Environments

The stable, non-corrosive nature of Partially Stabilized Zirconia MSZ supports high-precision dimensional calibration in coolant-rich environments.

- MSZ Ceramic Gauge Block ensuring long-term dimensional constancy

- MSZ Ceramic Plate supporting metrology surface applications

- Magnesia Stabilized Zirconia MSZ Ceramic Ring providing roundness stability references

Mechanical Structural Components for Wear-Resistant and Electrically Insulated Systems

Industrial assemblies benefit from the wear-resistant and electrically insulating properties of Magnesium Oxide Stabilized Zirconia Ceramic.

- Magnesia Stabilized Zirconia Ceramic Tube guiding abrasive or reactive flows

- Magnesia Stabilized Zirconia Ceramic Sleeve improving shaft alignment durability

- MSZ Ceramic Seal Ring maintaining sealing interfaces under cyclic loading

Integrated Manufacturing Solutions for ADCERAX® Magnesia Stabilized Zirconia Ceramic Components

One-Stop MSZ Ceramic Manufacturing Services

ADCERAX® delivers a unified manufacturing workflow for Magnesia Stabilized Zirconia (MSZ) Ceramic components, ensuring precision control from material preparation to final inspection.

High-consistency powder formulation and controlled granulation.

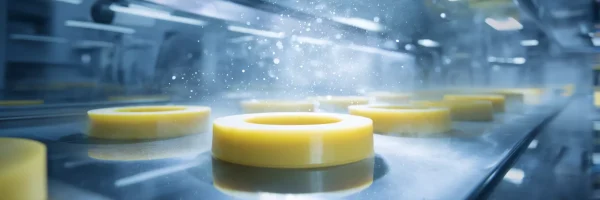

Pre-sinter shaping ensuring uniform geometry retention.

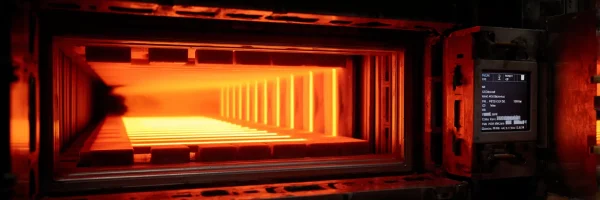

Precision thermal cycles for repeatable mechanical strength.

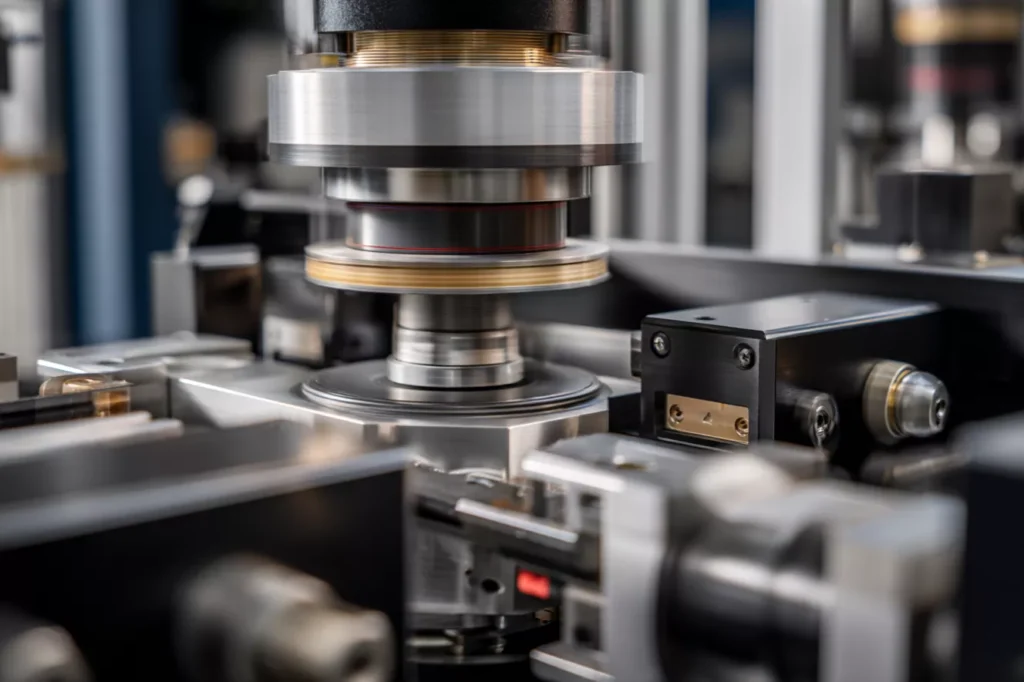

Multi-axis grinding achieving stable precision dimensions.

Mirror-level surfaces enabling reliable sealing performance.

Documentation framework supporting industrial audit needs.

Capabilities for MSZ Ceramic Manufacturing

ADCERAX® combines engineering consultation, drawing optimization, and rapid-response technical communication with a full suite of advanced machining assets dedicated to MSZ Zirconia Ceramic fabrication. This hybrid capability ensures both engineering depth and production reliability for demanding industrial sectors.

| Capability Category | Equipment / Specification | Engineering Value Provided |

|---|---|---|

| Precision CNC Grinding | 5-axis ceramic grinders (±0.01 mm) | Stable tolerances for rods, sleeves, rings |

| Ultra-Fine Polishing | Automated polishing lines (Ra <0.05 µm) | High-seal surfaces for pistons and valves |

| Isostatic Pressing | Cold isostatic press up to 200 MPa | Uniform density for MSZ tubes and plates |

| High-Temp Sintering | 1600–1750°C programmable furnaces | Controlled microstructure and mechanical strength |

| Metrology & Inspection | CMM, roundness testers, profilometers | Batch consistency and dimensional certification |

Industrial-Grade Processing Strength for Magnesia Stabilized Zirconia Components

CNC Grinding Stability & Micron Tolerance

Dimensional accuracy for MSZ Zirconia Ceramic components is achieved through controlled multi-axis grinding under high-precision measurement conditions.

Achieving ±0.01 mm tolerance stability consistently.

Maintaining profile accuracy with minimal wear.

Achieving <2 μm variation across batches.

Sub-Micron Polishing for Functional Surfaces

Surface quality for sealing, metering, and dynamic interfaces is produced through multi-stage slurry polishing optimized for Magnesia Stabilized Zirconia (MSZ) Ceramic components.

Delivering Ra <0.05 µm final roughness.

Improving contact surfaces with reduced friction.

Reducing sealing wear by over 30 percent.

High-Temp Sintering for Microstructure Integrity

Microstructure density and mechanical stability are formed through programmable thermal cycles precisely matched to MgO-ZrO₂ Ceramic sintering profiles.

Operating between 1600–1750°C consistently.

Limiting gradients to below 5°C per minute.

Reaching >96 percent theoretical density.

Let our advanced capabilities bring your ceramic component vision to life.

Customized Magnesia-Stabilized Zirconia MSZ Ceramics

Custom manufacturing for MSZ zirconia components is executed through data-driven engineering workflows and precise geometric adaptation based on application demands. Dimensional, thermal, and structural performance is matched to end-use conditions through controlled processing and material modeling.

Please contact ADCERAX® for a full evaluation of your MSZ zirconia customization requirements.

0.01 mm Tolerance

dimensional stability assurance

Send us your drawing, CAD file, or physical sample with material grade, dimensions, tolerances, and quantity. Our engineers will evaluate the design and provide a detailed quotation with lead time and pricing.

Once the quote is approved, we proceed with sample prototyping (1–50 pcs) if needed, for testing and validation.

After sample approval or direct confirmation, we begin batch manufacturing using CNC machining, sintering, and polishing. All parts undergo dimensional checks, material purity testing, and surface finish inspection.

Finished products are securely packed and shipped via DHL/FedEx/UPS or your preferred method. We support global delivery with full documentation.

Why Choose ADCERAX for Your MSZ Zirconia Ceramic Needs?

Choosing the right advanced ceramic supplier is crucial for the success of your industrial projects. ADCERAX stands out as a reliable and competitive partner.

Direct manufacturer eliminating intermediaries for cost-effective solutions without compromising quality.

20+ years of B2B experience providing unparalleled technical support and collaborative design.

Agile manufacturing for small-batch customization and rapid prototyping capabilities.

Stringent quality measures from raw material inspection to final product testing.

24-hour response guarantee with dedicated support for global clientele.

Trusted by global customers for advanced ceramic materials and precision components.

Engineering Answers for ADCERAX® Magnesia Stabilized Zirconia (MSZ) Ceramic Custom Fabrication

Magnesia Stabilized Zirconia (MSZ) Ceramic has a partially stabilized tetragonal phase that resists thermal shock by suppressing microcrack propagation. Its low thermal conductivity and controlled grain expansion reduce internal stress during rapid temperature changes. In industrial furnaces, this allows components to survive repeated 1200–1600°C cycling without distortion or fracture. This characteristic significantly reduces failure frequency in high-duty thermal systems.

The MgO-stabilized matrix delivers high hardness (HRA 88–90) and exceptional abrasion resistance. Under contact loads, the fine-grain microstructure minimizes surface fatigue and reduces wear rate compared to alumina or steel. In dosing pumps and valves, Magnesia Stabilized Zirconia (MSZ) Ceramic extends service life by withstanding long-term mechanical abrasion. This directly lowers maintenance intervals in continuous manufacturing lines.

- MSZ ceramics allow stable machining to ±0.01 mm due to their high green-body density and predictable shrinkage curves. ADCERAX® utilizes CNC grinding and controlled sintering to maintain dimensional consistency across batches. This precision is critical for sealing interfaces, metering gaps, and alignment-critical assemblies. It ensures long-term repeatability in automated equipment.

Magnesia-stabilized zirconia exhibits compressive strength exceeding 1900 MPa. The uniform tetragonal crystal structure distributes load evenly, preventing local mechanical failure. In pressurized flow systems or heavy mechanical assemblies, Magnesia Stabilized Zirconia (MSZ) Ceramic resists deformation far beyond the limits of metals. This reliability benefits high-pressure pumps and fluid-control hardware.

MSZ zirconia is chemically inert to acids, alkalis, salts, and organic solvents across wide temperature ranges. It forms no ionic exchange products and does not oxidize or leach contaminants. In chemical dosing, pH-adjustment modules, and corrosive pipelines, MSZ eliminates metal-ion contamination. This stability ensures product purity in chemical and pharmaceutical systems.

With multi-stage diamond slurry polishing, MSZ can reach Ra <0.05 μm. This smoothness improves sealing performance, reduces friction coefficients, and enhances wear resistance. For high-frequency mechanical motion or precision metering, ultra-low roughness reduces startup torque and prevents premature seal failure. This refinement improves performance stability in long-duration operations.

Magnesia Stabilized Zirconia (MSZ) Ceramic retains mechanical strength up to ~1600°C and maintains phase stability up to 2200°C. It resists grain growth, creep deformation, and softening that commonly affect alumina. In sintering trays, crucibles, or furnace accessories, MSZ supports heavy loads without warping. This enables long service life even in aggressive thermal environments.

Yes. Controlled sintering protocols deliver >96% theoretical density. Uniform microstructure minimizes internal flaws that otherwise cause cracking under stress. For load-bearing or pressure-sealing applications, this density ensures consistent mechanical behavior. It also provides better machining response and higher dimensional stability.

MSZ offers superior thermal shock resistance and lower thermal conductivity than YSZ. While YSZ excels in ionic conductivity and extreme strength, MSZ provides better stability for fluctuating thermal environments. In applications like furnace supports, crucibles, and high-ramp-rate processing, Magnesia Stabilized Zirconia (MSZ) Ceramic delivers more consistent durability. This makes it ideal for chemical and metallurgical systems.

MSZ ceramics exhibit high volume resistivity (>10¹² Ω·cm). This ensures stable insulation under high voltage, moisture, and temperature variations. In high-frequency sensors or electrically driven actuators, MSZ prevents leakage currents and signal distortion. This enhances equipment reliability in electrically sensitive environments.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.

Contact ADCERAX for Your MSZ Zirconia Ceramic Solutions

Ready to elevate your industrial applications with high-performance Magnesia Stabilized Zirconia (MSZ) Ceramic? Whether you need standard products or custom-engineered solutions, ADCERAX is your trusted partner.

info@adcerax.com

+(86) 0731-74427743 | WhatsApp: +(86) 19311583352

Within 24 hours