Custom Zirconia Ceramic Components Manufactured to Engineering Drawings by ADCERAX®

ADCERAX® specializes in providing zirconia ceramic custom components engineered for demanding industrial systems. Each part is crafted with precision to meet high expectations in durability, insulation, and corrosion resistance.

A tailored proposal from ADCERAX® can be requested today to meet your zirconia ceramic component needs. Trusted by global engineering firms, our solutions enable consistent performance even in high-stress environments.

Contact ADCERAX® today to receive a tailored proposal for your zirconia ceramic components.

2200°C

Max Operating Temp

What Makes Zirconia Ceramic Components an Engineering-Grade Solution?

Zirconia Ceramic Components are advanced structural materials designed to endure harsh industrial environments while offering high precision, corrosion resistance, and long-term dimensional stability.

With superior mechanical strength and electrical insulation, they are ideal for use in applications where traditional metals or plastics fail. These parts are extensively used in sectors such as fluid systems, optical alignment, filtration, and laboratory equipment.

Tailored variants like Zirconia Pad Printing Ceramic Ring, Zirconia Ceramic Shaft Sleeve, and Zirconia Ceramic Scraper can be fabricated to meet strict geometric and surface criteria.

Technical Specification of ADCERAX® Zirconia Ceramic Components

Zirconia Ceramic Components from ADCERAX® are engineered to meet stringent industrial requirements in strength, stability, and chemical resistance.

| Technical Specification Table | ||

|---|---|---|

| Property | Value Range (Typical) | |

| Material System | Yttria-Stabilized Zirconia (YSZ) / Magnesia-Stabilized Zirconia (MSZ) | |

| Purity | ≥ 94.5% ZrO₂ | |

| Hardness | 12–14 GPa | |

| Fracture Toughness | 7–10 MPa·m¹/² | |

| Flexural Strength | ≥ 950 MPa | |

| Compressive Strength | ≥ 2200 MPa | |

| Maximum Working Temperature | 1000–1400 °C (air); 2200 °C (inert) | |

| Thermal Expansion Coefficient | 10.3 × 10⁻⁶ /K | |

Key Performance Features of ADCERAX® Zirconia Ceramic Components

Zirconia ceramic parts exhibit a unique balance of mechanical integrity and functional versatility across many industries. Their advanced properties allow them to outperform stainless steel and alumina in extreme mechanical, thermal, and chemical conditions.

Mechanical Properties

Zirconia Structural Ceramic Components deliver superior toughness and wear resistance.

- High fracture toughness ensures longer service life

- Hardness up to 14 GPa resists abrasion and deformation

- Dimensional stability under mechanical stress

Chemical Inertness

These components maintain stability even in aggressive chemical media.

- Inert to acids, alkalis, and organic solvents

- Ideal for long-term use in corrosive environments

- No contamination risk during sensitive material processing

Electrical and Thermal Insulation

Zirconia Components For Industrial Equipment offer high insulation and thermal control.

- Volume resistivity >10¹⁴ Ω·cm to ensure electrical safety

- Thermal conductivity <3 W/m·K to minimize heat transfer

- Suitable for precision uses requiring stable insulation performance

Surface and Geometric Precision

Zirconia Ceramic Parts are manufactured to meet strict dimensional and surface finish requirements.

- Capable of sub-millimeter tolerance control

- Surface roughness optimized for high-precision assemblies

- Stable geometry maintained across thermal cycling

Industrial Zirconia Ceramic Parts Lineup from ADCERAX®

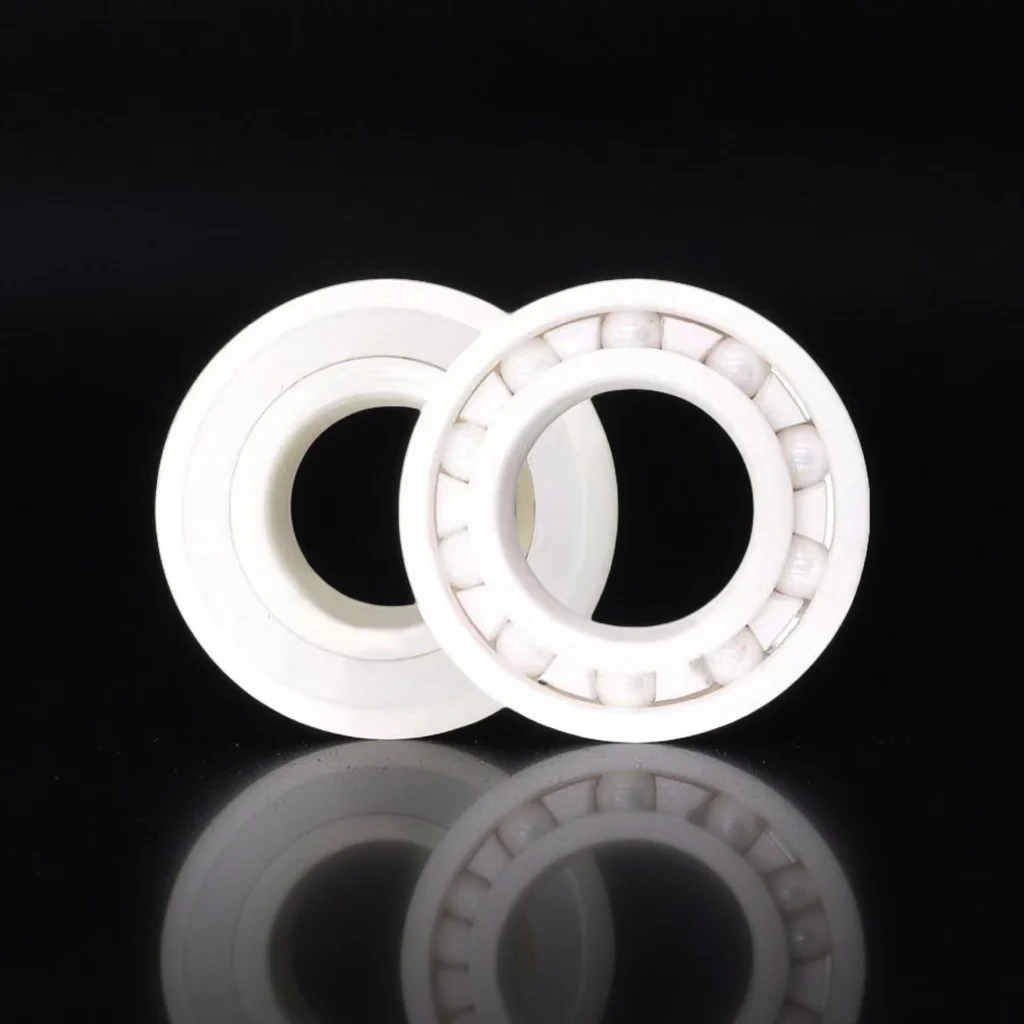

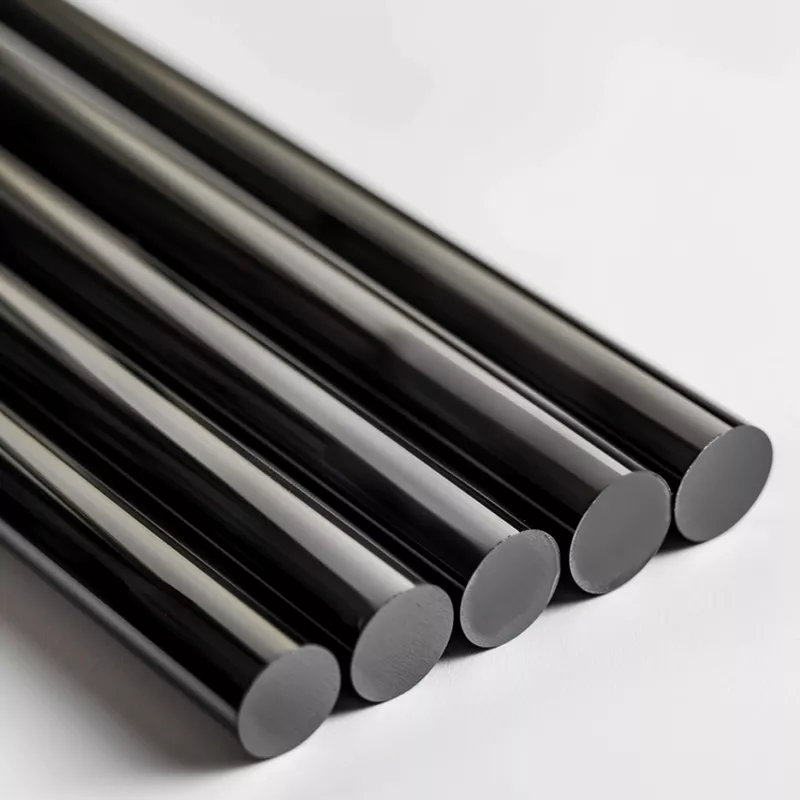

Structural & Bearing Components

Zirconia Structural & Bearing Components are engineered for high-load, high-precision applications where mechanical stability, wear resistance, and non-magnetic insulation are essential. This group includes shaft sleeves, ceramic bearings, structural rods, and alignment fixtures used across demanding fluid systems and motion assemblies.

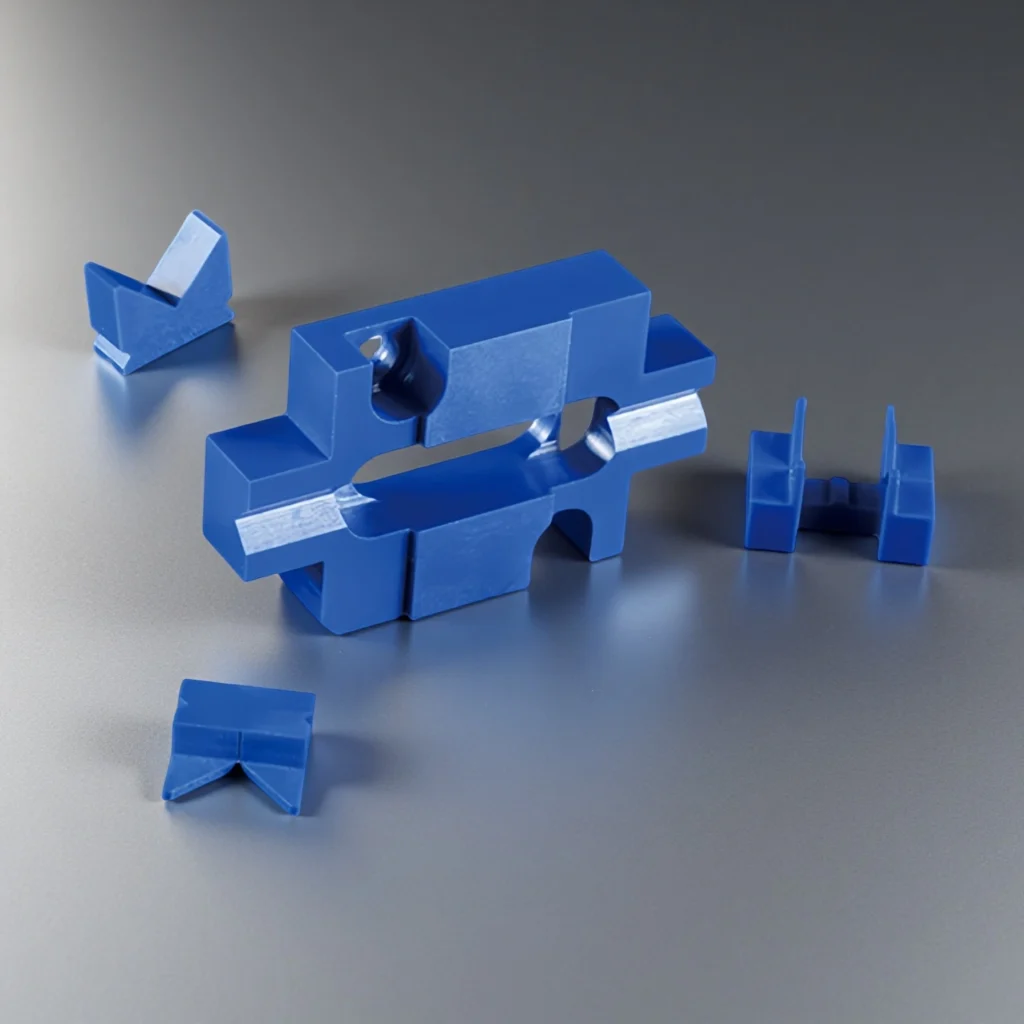

Positioning & Alignment Components

Zirconia Positioning & Alignment Components ensure repeatable precision and geometric stability in high-accuracy optical, electronic, and mechanical assemblies. These include alignment pins, V-grooves, substrates, and positioning fixtures designed for cleanroom integration and multi-axis alignment systems.

Pump & Fluid System Interfaces

Zirconia Pump & Fluid System Interfaces are built for corrosive, high-pressure environments requiring chemical stability, thermal resistance, and sealing precision. Core products such as sealing rings, pistons, spray nozzles, and flanges support long-term reliability in pumps, valves, and chemical delivery systems.

Dispersion & Grinding Components

Zirconia Dispersion & Grinding Components are optimized for high-energy milling, slurry mixing, and fine particle dispersion in chemically aggressive environments. With high density, abrasion resistance, and surface stability, these components—such as grinding jars, dispersion rotors, and mortar sets—ensure low-contamination processing and extended service life.

Looking for High-Precision Zirconia Ceramic Components?

ADCERAX® is committed to delivering precise, reliable, and customized solutions for your engineering needs. Whether for small-batch prototyping or batch-scale sourcing, our team provides full technical support across design, production, and logistics.

Ready to upgrade your components?

Let ADCERAX® help you meet your performance and delivery targets with industrial-grade zirconia ceramic components.

Zirconia Ceramic Components Applications Across Industrial Sectors

Zirconia Ceramic Components are widely adopted across sectors where mechanical reliability, chemical stability, and long-term dimensional control are essential. The following industries represent key application areas that benefit from our engineered ceramic parts.

Precision Mechanical & Fluid Equipment

Zirconia Components For Industrial Equipment are ideal for high-wear positions in pumps, valves, mixers, and bearing systems.

- In chemical dosing pumps, zirconia pistons and sealing rings deliver stable performance up to 2200 °C and under 2.2 GPa pressure.

- Ceramic shaft sleeves and cylinder sleeves are used in rotary fluid control, extending maintenance cycles by 3× compared to stainless steel.

- Bearings made from Industrial Zirconia Ceramic Components offer noise-free, lubricant-free operation in aggressive liquids and vacuum.

Electronics & Optical Alignment

Zirconia Ceramic Parts with high surface precision and electrical insulation are essential in alignment-critical optical systems.

- V-grooves and ferrules are used in fiber optic connectors, achieving sub-micron alignment tolerances and low insertion loss.

- Positioning pins and jigs ensure consistent fixture repeatability in semiconductor inspection systems.

- Non-conductive and anti-magnetic zirconia substrates help isolate sensitive components in power modules.

Energy & Electrochemical Systems

Zirconia Structural Ceramic Components provide thermal and electrochemical stability in demanding energy systems.

- Oxygen sensor chips made from YSZ deliver stable ionic conductivity from 600–1000 °C in exhaust monitoring.

- Zirconia parts in SOFC stacks withstand redox cycling, maintaining mechanical integrity for 2000+ hours.

- Spray nozzles and sealing rings in battery slurry mixing reduce contamination risk and maintain fluid consistency.

Laboratory Equipment & Material R&D

Zirconia Ceramic Components support contamination-free processing in lab-scale and pilot production environments.

- Milling jars and mortars offer ultra-low contamination for rare-earth, pigment, and catalyst grinding.

- Dispersion discs and rotors enable uniform nanoparticle deagglomeration in colloidal suspensions.

- Anti-stick scrapers and chemical-resistant trays facilitate processing of reactive samples and materials under test.

One-Stop Supplier for Zirconia Ceramic Components – Powered by ADCERAX®

Comprehensive Support Across the Entire Lifecycle

ADCERAX® provides end-to-end capabilities in the supply of zirconia ceramic components, encompassing technical evaluation, precision forming, and quality-controlled delivery. As a one-stop supplier, complete ceramic solutions are enabled from initial design through final machining, with no compromise on geometric complexity, delivery timelines, or batch flexibility.

- Engineering Design Assistance 2D/3D file integration, tolerance feasibility, bonding surface review

- Material Matching & Selection YSZ/MSZ/PSZ systems based on wear, insulation, or thermal load

- Non-Standard Geometry Development Chamfers, grooves, threads, multi-axis profiles

- Prototype-to-Production Scaling From one-off testing pieces to batch-ready configurations

- Global Logistics Integration Export packaging, shipping consolidation, customs documents ready

Full-Scale Manufacturing Capabilities for Zirconia Ceramic Components

Extensive in-house facilities support the production of zirconia ceramic components across complex geometries, critical tolerances, and rapid response timelines. All core processes—from green body forming to precision finishing—are managed under strict process control to ensure industrial-grade consistency and reliability.

| Manufacturing Capabilities Overview | |||

|---|---|---|---|

| Engineering & Process Control | Factory Equipment & Output Capability | ||

| 2D/3D CAD-CAM integrated toolpath programming | 5-axis CNC grinders (±0.01 mm repeatability) | ||

| ISO 9001-based process traceability documentation | High-pressure isostatic pressing systems (≥200 MPa) | ||

| CPK process capability analysis for critical steps | Vacuum sintering furnaces (up to 1700 °C, 0.5 m³ chamber volume) | ||

| Customized geometry review (chamfers, threads, slots) | Precision diamond polishing lines (Ra ≤ 0.2 µm for sealing surfaces) | ||

| Raw material lot control and performance validation | Multi-cavity batch forming (≥1,200 pcs/day for standard parts) | ||

customized zirconia Ceramic Components supplier

We specialize in custom zirconia ceramic components with special sizes, tight tolerances, and complex features. OEM and small-batch support available.

Customization Options

Extra-large / Extra-small diameters, non-standard thicknesses, and ultra-long / ultra-short lengths.

Provide higher - level dimensional accuracy and concentricity control than the standard.

Flanges, steps, threads, drilling holes, grooves, etc.

Adjust the material according to the application requirements.

Polish and grind the surface to achieve a specific surface roughness.

Customization Process

Send us your drawing, CAD file, or physical sample with material grade, dimensions, tolerances, and quantity. Our engineers will evaluate the design and provide a detailed quotation with lead time and pricing.

Once the quote is approved, we proceed with sample prototyping (1–50 pcs) if needed, for testing and validation.

After sample approval or direct confirmation, we begin batch manufacturing using CNC machining, sintering, and polishing. All parts undergo dimensional checks, material purity testing, and surface finish inspection.

Finished products are securely packed and shipped via DHL/FedEx/UPS or your preferred method. We support global delivery with full documentation.

Technical FAQs About ADCERAX® Zirconia Ceramic Components

Yes, all parts are produced using fully stabilized zirconia, including YSZ and MSZ grades, ensuring long-term phase stability, high hardness, and superior chemical resistance.

Polishing lines at ADCERAX® routinely achieve surface roughness of Ra ≤ 0.2 μm, especially for sealing rings, bearing races, and flow control interfaces.

Features such as blind bores, keyways, radial holes, multi-axis chamfers, internal threads, and complex cross-sections can be supported with 5-axis CNC machining.

All components are manufactured under contamination-controlled protocols, suitable for use in aggressive media and ultra-pure environments including battery slurry and catalyst applications.

Zirconia parts made from Yttria-Stabilized Zirconia can typically operate up to 1000 °C in air and up to 2200 °C under inert atmosphere, depending on part geometry.

ADCERAX® supplies components with typical dimensional tolerances of ±0.01 mm for precision shafts, sleeves, and alignment parts. For complex geometries, tighter limits may be achieved subject to review.

Applications span precision mechanical systems, filtration assemblies, fiber optics, energy conversion, and laboratory processing, with repeat orders from fluid handling and optical alignment OEMs.

Yes, all zirconia ceramic components are RoHS and REACH compliant and free from hazardous substances such as lead, cadmium, or PBB/PBDEs.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.

Partner with ADCERAX for Precision Zirconia Ceramic Components

Looking for a reliable zirconia ceramic components supplier? Let us help you with your next project.

info@adcerax.com

Tel.:

+(86) 0731-74427743

WhatsApp:

+(86)19311583352

Within 24 hours