Ceramic Valves & Components for Abrasive and Corrosive Application

ADCERAX is a ceramic valve supplier, offering ceramic ball valves, full lined ceramic lined ball valves, ceramic butterfly valves, ceramic gate/knife gate valves, plus ceramic valve seats and ceramic valve balls for abrasive slurry lines and corrosive chemical service. Material options include zirconia, silicon carbide, silicon nitride, and alumina-based wear ceramics. Stock items and custom-to-drawing machining support critical fit and sealing—helping reduce leakage, erosion wear, and unplanned downtime.

Send your drawing and media data to get a factory-direct solution engineered for longer service life.

What is Ceramic Valve?

A ceramic valve is an industrial valve (or a valve with ceramic wear parts) that uses ceramic components at the key wear and sealing zones—such as the seat, ball, liner, or disc—to handle abrasive, particle-laden, or chemically aggressive media.

It is commonly selected for slurry lines and corrosive chemical service because the ceramic contact surfaces help slow erosion at sealing edges, maintain more stable shutoff, and reduce leakage growth and unplanned downtime compared with conventional all-metal constructions in the same duty.

Features & Benefits of Ceramic Valve

✅Wear Life in Abrasive Slurry Duty

Ceramic-lined flow paths and ceramic trim slow edge erosion, helping extend service intervals in high-solids, high-velocity lines.

✅Leakage Growth Control

Hard sealing interfaces reduce scoring at seat/ball/disc contact zones, helping maintain shutoff stability over repeated cycles.

✅Custom Fit & Tolerance Control

Custom-to-drawing ceramic valve seats, balls, discs, and liners with defined OD/ID/length and sealing-face requirements to match parts.

✅Corrosion-Tolerant Operation

Performs in aggressive media across wide pH conditions where metal trims corrode and sealing performance drops.

✅Low Torque, Stable Actuation

Optimized sealing geometry and surface finish can reduce actuation torque and improve control repeatability.

✅High-Temperature Capability

Suitable for elevated-temperature service where polymers soften and conventional soft seats lose stability.

Ceramic Valve Properties

Ceramic valves help maintain stable shutoff and predictable wear in particle-laden or chemically aggressive flows by protecting key sealing and erosion zones. Use the table below to compare material options and select a valve lining/trim combination that fits your pressure drop, cycling rate, and service environment.

Ceramic Valve Technical Data

Alumina Ceramic Valve

Alumina ceramic valve — cost-effective wear resistance for abrasive media, helping keep shutoff stable and reduce leakage growth.

| Property | Unit | 96% Al₂O₃ | 99% Al₂O₃ | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

|---|---|---|---|---|---|---|---|---|---|

| Alumina content | % | 96 | 99 | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.75 | 3.88 | 3.89 | 3.91 | 3.92 | 3.93 | 3.95 | 3.98 |

| Flexural strength | MPa | 330 | 360 | 379 | 312 | 313 | 314 | 315 | 320 |

| Hardness | GPa | 11.5 | 13.5 | 14.1 | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 20–25 | 30–35 | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance (ΔT) | °C | 150 | 200 | — | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1600 | ≤1700 | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Dielectric strength | kV/mm | 8–10 | 10–12 | 11–13 | 12–14 | 12–15 | 13–16 | 14–17 | 15–18 |

| Volume resistivity (25°C) | Ω·cm | ≥1×10¹³ | ≥1×10¹⁴ | ≥3×10¹⁴ | ≥5×10¹⁴ | ≥1×10¹⁵ | ≥3×10¹⁵ | ≥5×10¹⁵ | ≥1×10¹⁶ |

- Values are typical ranges; they vary with Al2O3 content, firing profile, and final density.

Zirconia Ceramic Valve

Zirconia ceramic valve — higher toughness for cycling duty, improving chip resistance and maintaining sealing stability in harsh service.

| Property | Unit | Typical Range | Why Buyers Specify It |

|---|---|---|---|

| Density | g/cm³ | 4.00 – 4.30 | Indicates densification and batch consistency |

| Flexural Strength | MPa | 700 – 1,200 | Impacts handling breakage risk and safety margin |

| Fracture Toughness | MPa·√m | 6 – 10 | Key ZTA advantage for edge-chipping and crack resistance |

| Hardness (Vickers) | GPa | 14 – 17 | Affects wear/scratch resistance and machinability |

| Thermal Conductivity | W/m·K | 18 – 30 | Drives heat spreading performance (typically below AlN) |

| CTE (20–300°C) | ×10⁻⁶ /K | 8.0 – 9.5 | Influences thermal-cycling stress and material matching |

| Dielectric Strength | kV/mm | 10 – 15 | Determines insulation margin (depends on thickness/surface) |

| Volume Resistivity (25°C) | Ω·cm | 10¹² – 10¹⁴ | Indicates insulation stability and leakage risk |

- Values are typical ranges; they vary with ZrO₂ content, firing profile, and final density.

Silicon Carbide Valve

SIC ceramic valve — strong erosion and corrosion resistance for severe slurry and aggressive chemicals, extending service life in wear-critical zones.

| Property | Specification |

|---|---|

| Material System | RBSiC (80% SiC, 20% free Si) / SSiC (≥99% SiC) |

| Maximum Operating Temperature | ≤1380°C (RBSiC) / ≤1600°C (SSiC) |

| Bulk Density | 3.02 g/cm³ (RBSiC) / 3.10 g/cm³ (SSiC) |

| Open Porosity | <0.1% |

| Flexural Strength (20°C) | 250 MPa (RBSiC) / 380 MPa (SSiC) |

| Flexural Strength (1200°C) | 280 MPa (RBSiC) / 400 MPa (SSiC) |

| Compressive Strength | 1000–2200 MPa |

| Elastic Modulus | 330 GPa (RBSiC) / 420 GPa (SSiC) |

| Thermal Conductivity | 45 W/m·K (RBSiC) / 74 W/m·K (SSiC) |

| Thermal Expansion Coefficient | 4.1–4.5 ×10⁻⁶/K |

| Hardness | 2600–2800 kg/mm² |

| Chemical Stability Range | pH 2–12 |

| Oxidation Stability | <1% microstructural oxidation after 50 cycles (1000°C → RT) |

- Values are typical ranges; they vary with SiC content, firing profile, and final density.

Silicon Nitride Valve

Si₃N₄ ceramic Valve — High strength with good thermal stability, supporting reliable performance in demanding mechanical duty and repeated cycling.

| SiN4 Type | Gas pressure sintering Si3N4 | Hot pressing sintering Si3N4 | High thermal conductivity Si3N4 |

|---|---|---|---|

| Density (g/cm³) | 3.2 | 3.4 | 3.5 |

| Texture strength (MPa) | 300 | 300-320 | 300-320 |

| Young Modulus | 300 | 300 | 300 |

| Poisson’s ratio | 0.25 | 0.25 | 0.25 |

| Hardness (GPa) | 15 | 15 | 15 |

| Maximum working temperature (°C) | 1100 | 1200 | 1200 |

| Thermal expansion coefficient (Mm/m·K) | 3 | 3 | 3 |

| Thermal conductivity (W/m·K) | 15 | 15 | 15 |

| Thermal shock resistance (ΔT °C) | 550 | 580 | 600 |

- Values are typical ranges; they vary with silicon nitride ceramic content, firing profile, and final density.

High Quality Ceramic Valve Products

Choose a ceramic valve by duty—on/off isolation, throttling control, slurry handling, or corrosive service—then match alumina, zirconia, silicon carbide, or silicon nitride to your media, solids loading, temperature, and wear risk. ADCERAX supplies ceramic valve products and trim sets for industrial service.

alumina ceramic valve

Alumina ceramic valves suit many wear and corrosion duties where cost-effective protection and stable shutoff are required over long service intervals.

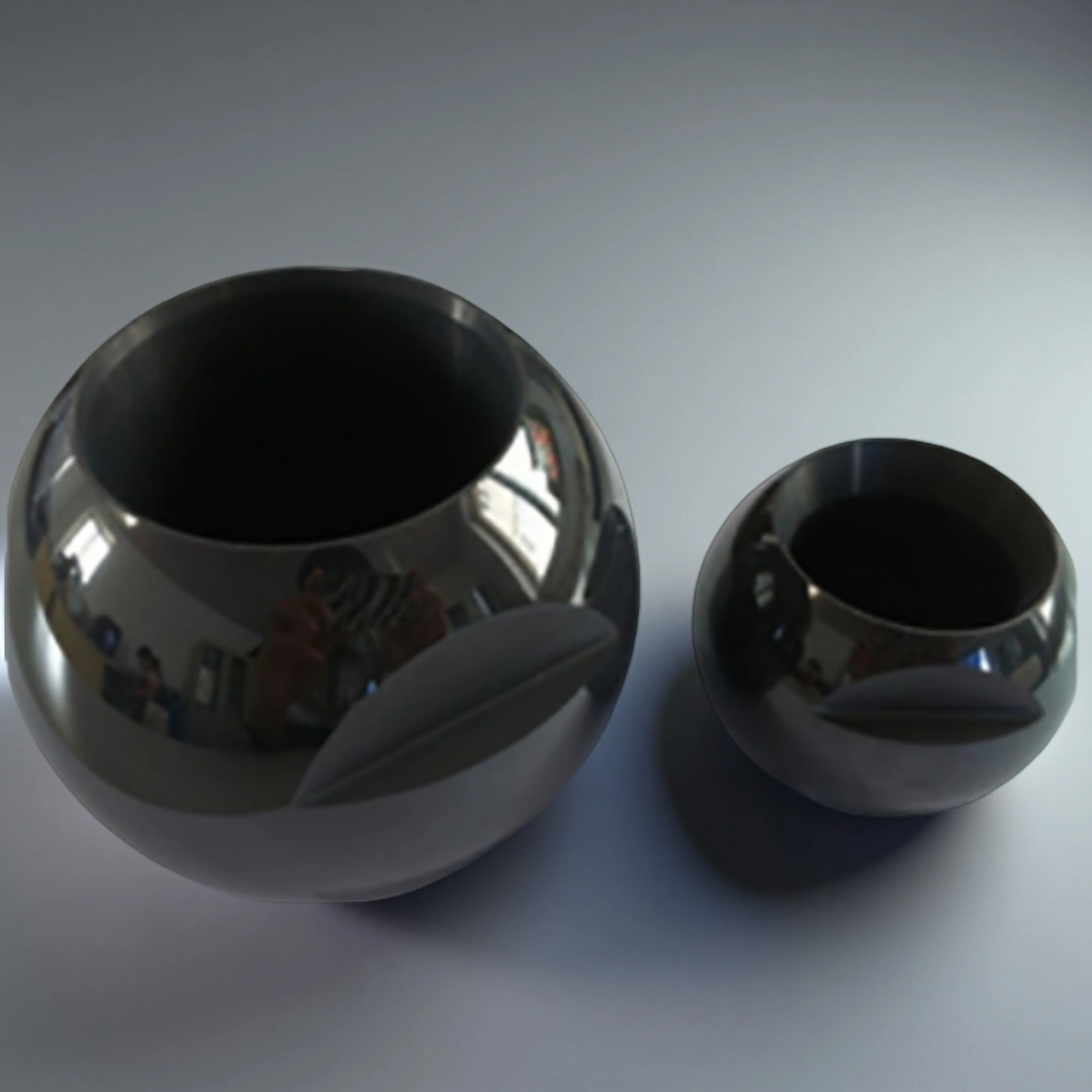

zirconia ceramic valve

Zirconia ceramic valves are chosen when higher toughness and impact tolerance are needed, helping maintain reliable sealing under repeated cycling.

silicon carbide Ceramic Valve

Silicon carbide ceramic valves are ideal for corrosive, high-wear service, especially where erosion and chemical attack occur together at sealing edges.

Silicon nitride Ceramic valve

Silicon nitride valves support demanding mechanical duty with high strength and stable cycling performance, reducing wear-driven drift in shutoff behavior.

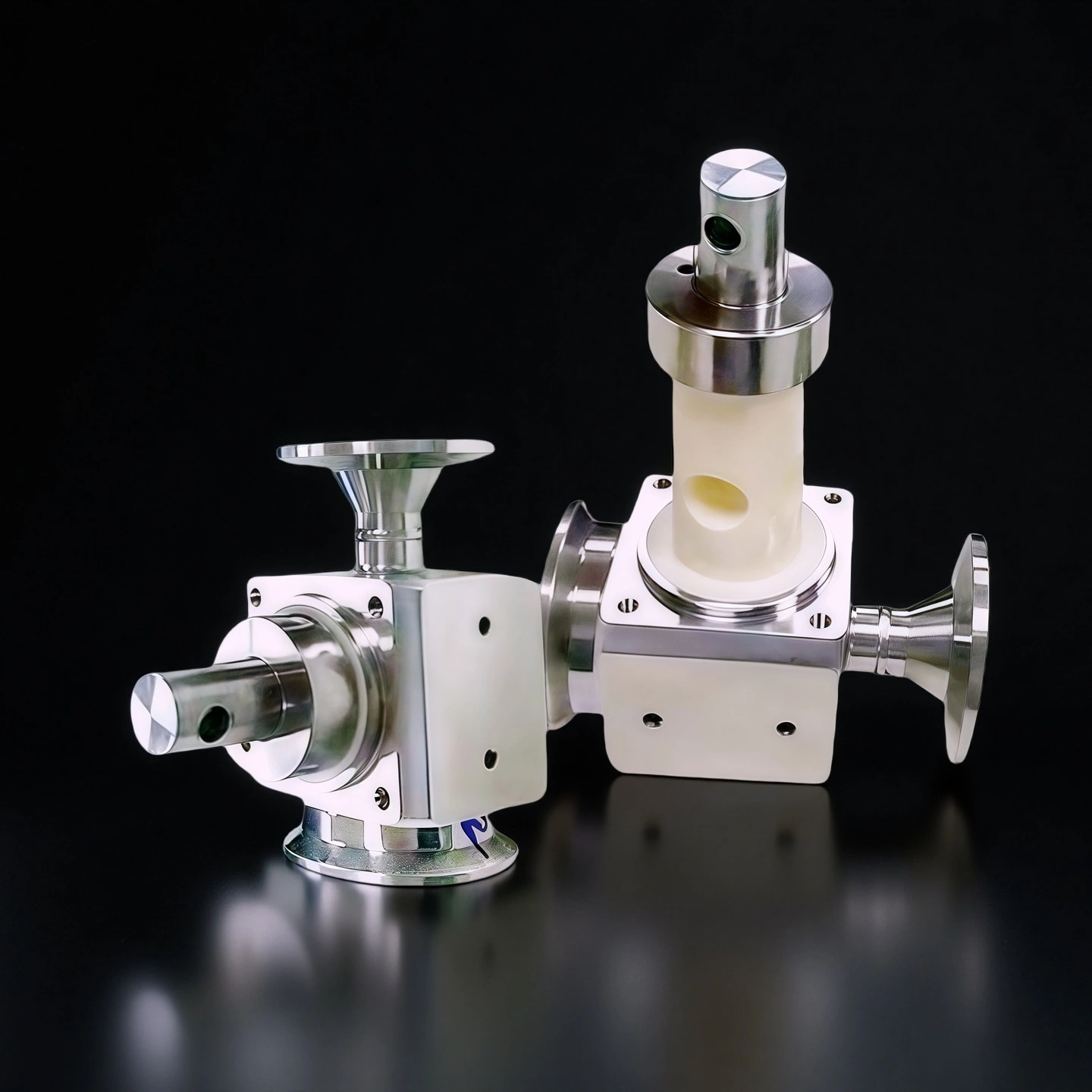

Ceramic Ball Valve

Delivers tight shutoff and smooth switching in abrasive or corrosive media, with wear-resistant sealing surfaces that help slow leakage growth over long cycles.

ceramic butterfly valves

Offer a compact, low-torque design for larger lines, using protected sealing zones to reduce erosion and keep performance stable in particle-laden flow.

ceramic gate valves

Provide dependable isolation for slurry and solids-handling duty, with robust flow-path protection that resists scoring and sticking during frequent open/close operation.

Ceramic Filling Valve

Supports repeatable filling accuracy by maintaining consistent sealing and wear control at critical interfaces, helping reduce drift and unplanned stoppages in harsh fluids.

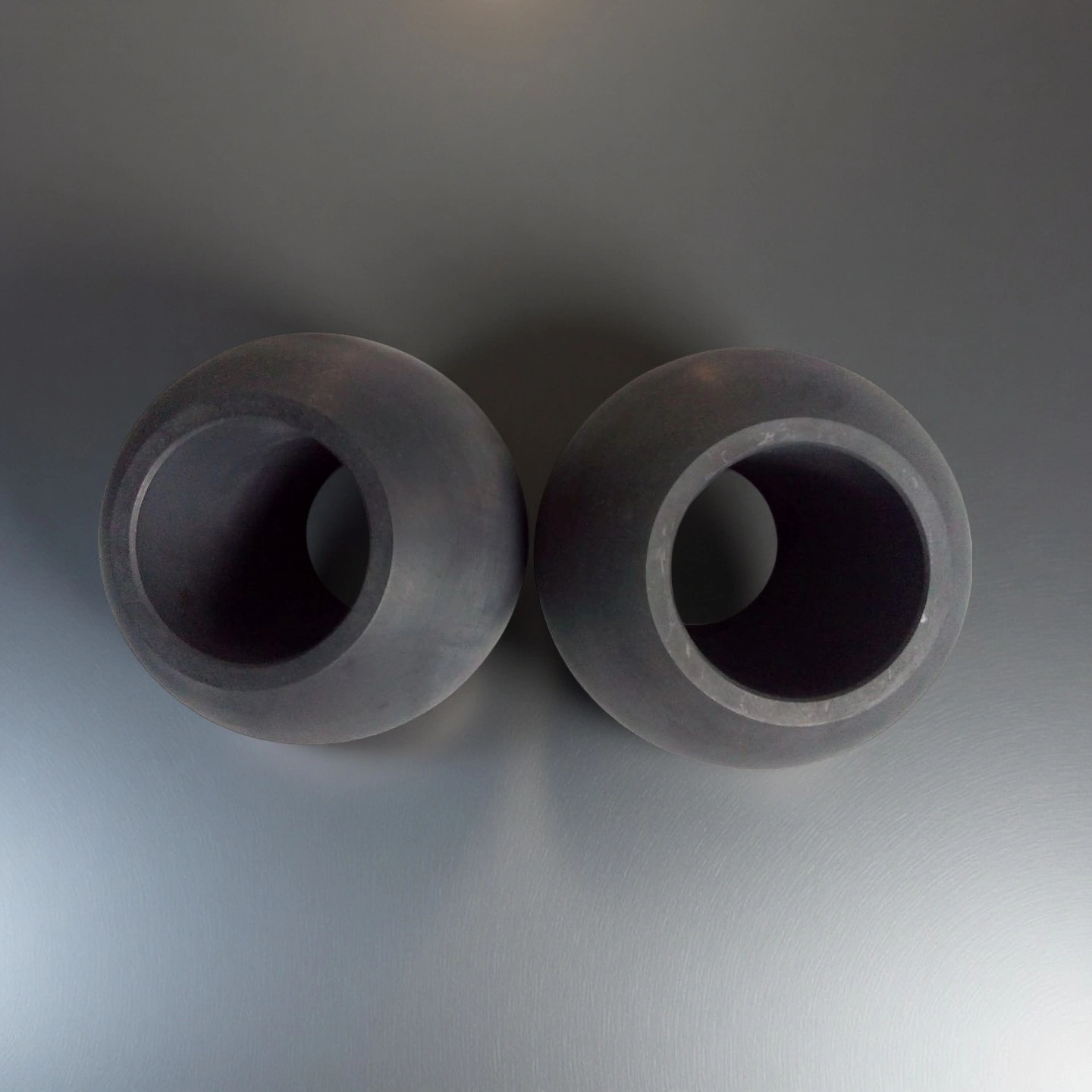

Ceramic Valve Ball

Wear-resistant valve balls help maintain stable shutoff and smooth switching in abrasive or corrosive media, reducing leakage growth as cycles accumulate.

Pneumatic Knife Gate Valve

Pneumatic actuation delivers fast, consistent isolation in slurry duty, helping prevent sticking and keeping operation reliable under frequent open/close cycles.

Electric Actuated Knife Gate Valve

Electric actuation supports steady, repeatable positioning for slurry isolation, improving control consistency where remote operation and stable torque matter.

ceramic valve discs

Ceramic valve discs protect critical sealing and flow edges against erosion, helping maintain performance and reduce wear-driven drift in demanding service.

Engineering-first ceramic valve supply—built around your failure mode, not a catalog.

Send your drawing or specs for a fast quote on ceramic valves and ceramic valve components. Standard options support quick replacement, and custom-to-drawing machining is available for critical trim such as ceramic valve seats, ceramic valve balls, liners, and sealing interfaces—restoring shutoff stability and wear life without redesigning the whole line.

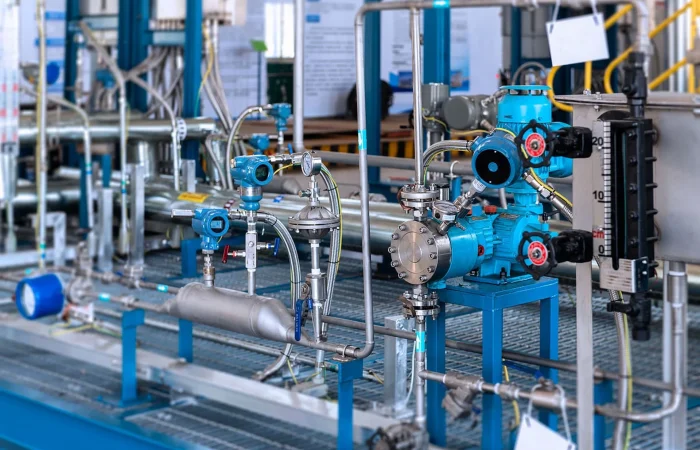

Ceramic Valve Applications

Ceramic valves are most valuable in abrasive slurry lines and corrosive chemical service, where sealing edges and flow paths wear quickly in conventional designs. Use the scenarios below to match valve type and ceramic system to your media, duty cycle, and maintenance target.

Abrasive Slurry Transfer (Mining / Mineral Processing)

✍🏻Best-fit ceramic valves: Ceramic lined ball valve, ceramic knife gate valve, ceramic ball valve

📍Why it matters: Particles erode sealing edges and create leakage growth after repeated cycles.

🧩What ADCERAX high quality ceramic valves improve: Consistent fit and sealing stability with wear-controlled contact zones—helping slow leakage growth and extend maintenance intervals.

Corrosive Chemical Transfer (Acids / Alkalis / Salts)

✍🏻Best-fit ceramic valves: Ceramic lined ball valve, ceramic ball valve, ceramic valve seats & balls (trim)

📍Why it matters: Chemical attack plus wear accelerates seat damage and shortens service life.

🧩What ADCERAX high quality ceramic valves improve: Controlled sealing interfaces and repeatable production—supporting stable shutoff and predictable service intervals.

High-Solid Process Lines (Crystals / Pigments / Catalysts / Slurries)

✍🏻Best-fit ceramic valves: Ceramic V-ball (by project), ceramic lined ball valve

📍Why it matters: High-solid media can cause scoring, sticking, and unstable control in throttling duty.

🧩What ADCERAX high quality ceramic valves improve: Media-matched wear surfaces and defined fit control—delivering steadier operation and less wear-driven drift.

Pulp & Paper Stock and Coating Slurries

✍🏻Best-fit ceramic valves: Ceramic ball valve, ceramic lined ball valve, knife gate valve

📍Why it matters: Fibers and fillers can lodge in sealing zones and drive frequent maintenance.

🧩What ADCERAX high quality ceramic valves improve: Batch-consistent fit and protected sealing zones—helping keep shutoff stable and reduce wear-triggered interventions.

Custom Ceramic Valve Wholesaler

ADCERAX custom ceramic valves and ceramic valve components are made to your drawing or sample, including key interfaces, seat/ball or disc fit, lining coverage, flow-path geometry, and sealing details for stable shutoff. Typical customization lead time is 2–9 weeks, depending on material choice, tolerances, and complexity.

Customization Options

Define the valve duty first—on/off isolation, throttling control, slurry service, or corrosive transfer—then confirm pressure, temperature, solids loading, and cycle frequency. Clear duty matching prevents wrong trim selection, reduces leakage growth, and avoids premature wear.

Share your drawing or sample for critical interfaces: face-to-face length, flange/connection standard, bore size, seat pocket, ball/disc fit, stem/shaft interface, and sealing land geometry. Controlled fit is the key to stable shutoff, repeatable operation, and predictable wear life.

Set the flow path around your media behavior—abrasive particles, crystallizing fluids, fibers, or high solids—and specify lining coverage and edge protection on erosion zones. Details like port shape, liner thickness, purge/flush options, and seat protection help reduce clogging, scoring, and pressure-loss drift.

Choose the ceramic system based on corrosion and wear severity, then define surface requirements on sealing and sliding areas. Specifying sealing face finish, matching of ball/seat pairs, and critical tolerance zones improves shutoff stability, reduces scoring, and extends maintenance intervals.

Customization Process

Send valve type, media details, pressure/temperature, solids loading, and duty cycle, plus your drawing or sample. Add quantity, target lead time, and destination.

We confirm critical valve interfaces and sealing zones: face-to-face, connection standard, bore, seat/ball fit, lining coverage, and tolerances.

We machine ceramic valve components to spec and inspect critical dimensions per batch for consistent fit and shutoff. Inspection records are available.

Parts are protected, labeled, and packed for transit to prevent chipping. Export-ready shipment is arranged with standard documents and clear carton marking.

Why Choose ADCERAX as Your Ceramic Valve Supplier?

ADCERAX supports export supply with controlled production and batch inspection for consistent fit and shutoff. Parts are transit-protected, labeled, and shipped with export-ready documents. Fast response to drawings and operating conditions confirms interfaces, tolerances, and lead time.

Competitive pricing with strict quality control from raw material sourcing to final delivery

Professional team providing comprehensive technical support and collaborative design

Small batch orders to large-scale production with complex geometries and tight tolerances

24-hour response and 24-hour dispatch for standard items, 3-7 weeks for custom orders.

High Quality China Ceramic Valve Factory-ADCERAX

ADCERAX has worked in advanced ceramics for over 20 years and supports ceramic valves and valve components for abrasive slurry and corrosive service.

We supply standard parts and custom-to-drawing components worldwide, enabling fast quoting, engineering review, and repeatable production control. With documented inspection and protective packing, we help buyers reduce leakage growth, extend maintenance intervals, and maintain stable replacement cycles.

End-to-End Manufacturing for Ceramic Valves

ADCERAX runs an end-to-end workflow for ceramic valves and valve components—from drawing review to forming, sintering, precision machining, finishing, and inspection. The goal is simple: hold sealing fits, protect wear zones, and keep repeat orders consistent.

We confirm media, solids loading, pressure/temperature, cycle rate, and key interfaces to avoid mismatch.

We control face-to-face features, seat pockets, ball/disc fit, and sealing lands for stable shutoff.

Parts are cleaned and protected to prevent edge damage and mix-ups on sealing interfaces.

We produce dense blanks with controlled firing for stable structure and consistent dimensions before machining.

We set finish on sealing zones to reduce scoring and slow leakage growth over long cycles.

We inspect critical dimensions per batch, with records for incoming QC and repeat orders.

FAQs About Ceramic Valve

A Ceramic Ball Valve uses a spherical ceramic ball for on/off control and is ideal for rapid operation.

A Ceramic Disc Valve employs a rotating ceramic disc for fine flow regulation and frequent adjustments.

Choose ceramic when failure is driven by erosion at sealing edges, scoring, leakage growth, or chemical attack that repeatedly damages metal trims and forces frequent maintenance.

If your main problem is isolation under slurry, knife gate or gate styles are common; if you need tight shutoff and switching, ball-valve configurations are typical; for larger line sizes with compact geometry, butterfly styles are frequently used. The correct choice depends on solids loading, particle size, and cycle frequency.

Common modes include edge chipping at sealing zones, scoring from hard particles, loss of shutoff due to seat wear, and sticking when solids pack into clearances. Correct fit, sealing geometry, and media-aware flow-path design reduce these risks.

Focus on the sealing interface: specify seat/ball or seat/disc fit, define sealing land geometry, and align surface finish requirements to reduce scoring. Also consider whether purge/flush features or protected edges are needed at the highest-velocity zones.

Send the valve type and size, media description, solids %, particle size range, temperature, pressure/ΔP, cycle rate, connection standard, and your drawing or sample. If you have a failure photo or wear pattern, it helps confirm where erosion is concentrated.

High-frequency customization targets include valve seats, valve balls, valve discs, liners, sealing lands, and interface features that control fit and repeatable shutoff. Many customers customize trim first to improve performance without redesigning the whole system.

Ceramic valves usually cost more upfront than regular metal or elastomer-seated valves because they target erosion and corrosion at sealing zones. In abrasive slurry or corrosive duty, they often lower total cost by extending service intervals and reducing downtime; in clean, low-wear fluids, regular valves are typically the better value.

You can buy a high quality ceramic ball valve from ADCERAX, a factory-direct supplier offering standard options and custom-to-drawing solutions with engineering support and export-ready delivery.

Ceramic valve pricing depends on your failure mode and how you control it—solids loading, particle hardness, ΔP, and cycle frequency set the wear intensity, while sealing-fit targets set the manufacturing complexity. Share your media and interfaces, and ADCERAX can recommend the right wear-focused solution instead of over-specifying cost.

Yes—ADCERAX supplies U.S. buyers with export-ready packaging, batch inspection control, and repeat-order consistency. If you want a fast quote, send your specs and we’ll confirm interfaces and sealing zones first.

Ceramic solutions are chosen when erosion and corrosion drive unpredictable maintenance—especially when sealing edges wear and leakage grows over time. If you’re replacing valves too often or fighting shutoff instability, send your wear photos or symptoms and ADCERAX will match a ceramic valve/trim approach to your duty.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

info@adcerax.com

Telephone: +(86) 0731-74427743

WhatsApp: +(86) 19311583352

Within 24 hours

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.