High-Performance Nitride Bonded Silicon Carbide Ceramic Solutions by ADCERAX®

Designed for extreme thermal cycles and structural loading environments, Nitride Bonded Silicon Carbide Ceramic components maintain dimensional stability where conventional refractories fail.

These ceramics support demanding operations in firing systems, molten metal handling, and advanced material processing under long service durations.

Contact ADCERAX® to configure engineering-grade NBSiC Ceramic solutions for your application.

≤0.3% under load

survives 30+ rapid cycles

reliable up to 1400°C

mass gain <0.1%

What Defines Industrial-Grade Nitride Bonded Silicon Carbide Ceramics

Nitride Bonded Silicon Carbide Ceramic is a reaction-bonded composite material formed through the nitridation of silicon carbide to create a dense, load-bearing microstructure.

This material delivers stable thermal, chemical, and mechanical performance in industrial environments requiring high strength and minimal deformation.

Across kiln systems, metal handling, and thermal processing operations, NBSiC Ceramic provides consistent reliability under extreme temperatures.

retains >80% strength at 1200°C

withstands repeated 1400°C cycles

maintains ~10⁶ Ω·cm resistivity

corrosion mass gain <0.1%

Comprehensive Properties of ADCERAX® Nitride Bonded Silicon Carbide Ceramics

Material behavior of Nitride Bonded Silicon Carbide Ceramic reflects its suitability for high-load and high-temperature industrial applications.

Thermal Properties of NBSiC Ceramic

| Thermal Property | Typical Value / Range | Engineering Notes |

|---|---|---|

| Maximum Service Temperature | 1350–1450°C | Stable under continuous high-temperature firing |

| Thermal Conductivity | 15–20 W/m·K | Enables uniform heat distribution in kilns |

| Thermal Expansion Coefficient | ~4.5 × 10⁻⁶ /K | Prevents thermal distortion and cracking |

| Thermal Shock Resistance | ≥ 30 rapid cycles | Survives fast heating/cooling cycles |

Electrical Properties of NBSiC Ceramic

| Electrical Property | Typical Value / Range | Engineering Notes |

|---|---|---|

| Electrical Resistivity | ~10⁶ Ω·cm | Stable insulating performance at high temperatures |

| Dielectric Stability | Consistent at 1200°C+ | Prevents conductivity drift during firing |

| Surface Resistivity | High resistive behavior | Suitable for furnace insulation components |

| Leakage Current Behavior | Very low under heat | Ensures electrical isolation in thermal systems |

Chemical Properties of NBSiC Ceramic

| Chemical Property | Typical Value / Range | Engineering Notes |

|---|---|---|

| Oxidation Resistance | Mass gain <0.1% | Withstands oxidizing atmospheres in kilns |

| Molten Metal Reaction | Excellent vs. Al alloys | Critical for riser tubes and crucibles |

| Acid/Base Stability | High chemical inertness | Resistant to kiln gases, fluxes, slags |

| Corrosion Rate | Extremely low | Supports long operating cycles without degradation |

Mechanical Properties of NBSiC Ceramic

| Mechanical Property | Typical Value / Range | Engineering Notes |

|---|---|---|

| Flexural Strength (RT) | 120–160 MPa | Supports kiln plates and beams under load |

| High-Temperature Strength Retention | >80% at 1200°C | Maintains structural reliability during service |

| Creep Deformation Rate | ≤0.3% under load | Prevents sagging in long-term firing |

| Density | 2.60–2.75 g/cm³ | Balanced strength-to-weight ratio |

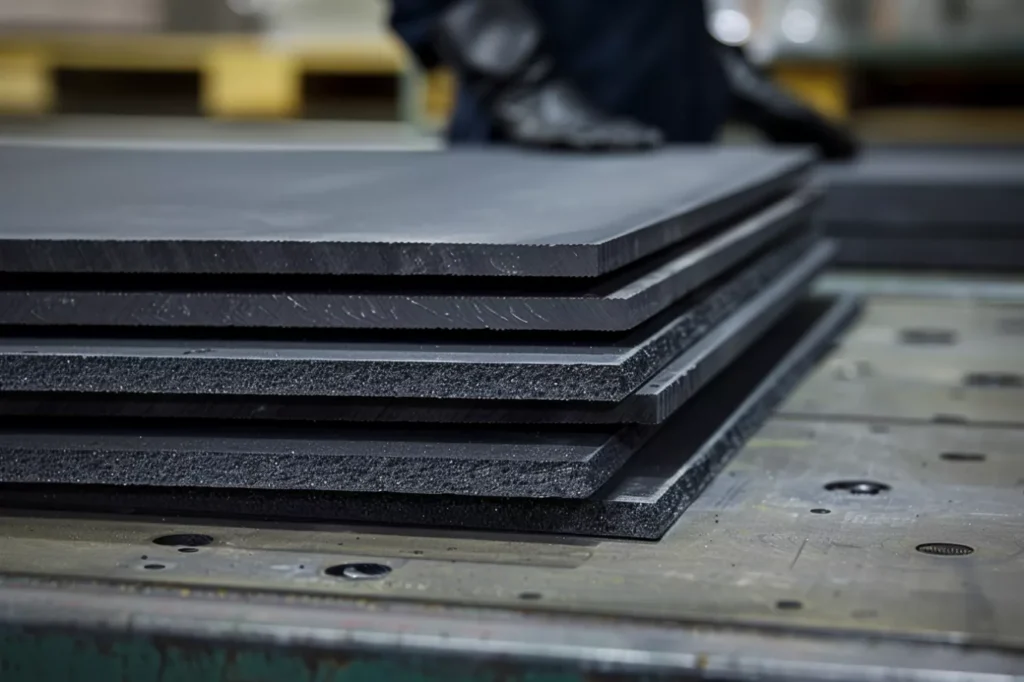

ADCERAX® Product Range of Nitride Bonded Silicon Carbide Ceramics

The following product configurations highlight how Nitride Bonded Silicon Carbide Ceramic components operate reliably across diverse thermal and structural industrial environments.

NBSiC Kiln Plate

Engineered kiln plates supporting stable firing performance.

- Resists deformation during 1400°C cycles

- Maintains flatness within 0.5 mm

- Ensures uniform heat spreading efficiency

NBSiC Riser Tube

Designed for molten aluminum handling in casting operations.

- Withstands corrosion from Al alloys

- Supports casting cycles exceeding 2000h

- Maintains wall cleanliness under 5% buildup

NBSiC Beam

High-strength support beams for multi-layer kiln structures.

- Carries spans exceeding 800 mm

- Limits creep deformation below 0.3%

- Stabilizes loads during thermal cycles

Cylindrical NBSiC Crucibles

Cylindrical crucibles for controlled high-temperature reactions.

- Endures over 30 thermal shocks

- Maintains wall uniformity within 0.3 mm

- Resists chemical attack during reactions

Square NBSiC Crucible

Square crucibles offering increased capacity and stability.

- Handles temperature gradients up to 1400°C

- Controls corner stress below 0.2%

- Maintains flat heating distribution consistency

High-Performance NBSiC Parts for Demanding Industrial Systems

View Full RangeWe maintain a ready stock of standard NBSiC ceramic products, ensuring 24-hour dispatch for urgent requirements, enabling you to minimize downtime and maintain operational continuity.

Application Fields of ADCERAX® Nitride Bonded Silicon Carbide Ceramics

High-Temperature Processing Systems

Nitride Bonded Silicon Carbide Ceramic have been utilized for stable operation under intense thermal environments.

- NBSiC Kiln Plate maintains dimensional stability

- NBSiC Beam supports multi-layer firing loads

- Cylindrical Crucible withstands repeated thermal shocks

Molten Metal Handling Systems

This category depends on Nitride Bonded Silicon Carbide Ceramic components for corrosion resistance and operational consistency.

- NBSiC Riser Tube prevents molten aluminum corrosion

- Cylindrical Crucible maintains wall uniformity during melting

- NBSiC Kiln Plate resists slag-induced thermal gradients

Materials Characterization Facilities

Testing environments rely on NBSiC Ceramic components for controlled heating profiles and structural rigidity.

- Square Crucible improves batch heating uniformity

- Cylindrical Crucible ensures reactive material containment

- NBSiC Beam resists deformation during heating cycles

Kiln Structural Support Systems

These structures integrate Nitride Bonded Silicon Carbide Ceramic elements to enhance furnace stability and load endurance.

- NBSiC Beam supports extended-span kiln frameworks

- Kiln Plate distributes heavy firing loads uniformly

- Square Crucible withstands repeated batch temperatures

Thermal Chemical Processing Units

Chemical and thermal reaction systems benefit from Nitride Bonded Silicon Carbide Ceramic for high inertness and heat resistance.

- Cylindrical Crucible tolerates corrosive reaction atmospheres

- Square Crucible maintains structural strength during reactions

- NBSiC Riser Tube avoids buildup in reactive environments

Factory Strength of ADCERAX® Nitride Bonded Silicon Carbide Ceramics

One-Stop Processing Services for NBSiC Ceramic Components

ADCERAX® offers a unified workflow for processing Nitride Bonded Silicon Carbide Ceramic components across multiple forming and finishing stages. Each procedure is coordinated to support stable performance in demanding thermal and structural applications.

enabling stable shaping across production stages

producing dense microstructure under controlled firing

ensuring complete traceability throughout production

achieving consistent dimensional tolerance stability

optimizing thermal interaction during repeated cycles

supporting varied geometries for industrial applications

Core Strengths Behind NBSiC Ceramic Manufacturing Excellence

Fabrication of Nitride Bonded Silicon Carbide Ceramic products is supported by a combination of technical expertise and controlled equipment capabilities. These strengths maintain structural stability and material reliability across demanding industrial conditions.

| Capability Type | Key Specification / Description |

|---|---|

| Forming Equipment | ISO-press systems shaping multi-size green bodies |

| High-Temperature Furnaces | Reaction-bonding chambers operating up to 1450°C |

| Machining Systems | CNC platforms maintaining ±0.2 mm tolerance |

| Inspection Instruments | Flexural testing verifying 120 MPa+ strength |

| Dimensional Measurement | Digital metrology ensuring geometric consistency |

| Thermal Testing Setup | Shock simulation exceeding 30 cycles |

Advanced Processing Workflows for ADCERAX® Nitride Bonded Silicon Carbide Ceramics

High-Temperature Reaction Bonding Processing

This workflow establishes the final structure of Nitride Bonded Silicon Carbide Ceramic through controlled high-temperature reaction bonding.

reaching controlled 1450°C firing

producing dense microstructural bonding

ensuring <0.3% dimensional deviation

CNC Dimensional Finishing for Structural Accuracy

This finishing stage stabilizes the geometric precision of Nitride Bonded Silicon Carbide Ceramic components under strict tolerance control.

achieving ±0.2 mm tolerance stability

ensuring low-chipping surface formation

maintaining repeatability within 0.1 mm

Thermal Shock and Load Reliability Conditioning

This conditioning process confirms the reliability of Nitride Bonded Silicon Carbide Ceramic components under repeated thermal and mechanical stresses.

exceeding 30 rapid thermal cycles

validating 120 MPa strength retention

reproducing 80°C/min temperature transitions

Let our advanced capabilities bring your ceramic component vision to life.

Engineering Services for ADCERAX® NBSiC Components

Custom fabrication of Nitride Bonded Silicon Carbide Ceramic components enables precise adaptation to diverse industrial thermal and structural environments. Each configuration is engineered to align with demanding operational conditions including cycling temperatures, corrosive media, and mechanical loading.

For detailed customization parameters, please contact ADCERAX® for technical consultation.

30 Cycle Shock

rapid heat change resistance

Send us your drawing, CAD file, or physical sample with material grade, dimensions, tolerances, and quantity. Our engineers will evaluate the design and provide a detailed quotation with lead time and pricing.

Once the quote is approved, we proceed with sample prototyping (1–50 pcs) if needed, for testing and validation.

After sample approval or direct confirmation, we begin batch manufacturing using CNC machining, sintering, and polishing. All parts undergo dimensional checks, material purity testing, and surface finish inspection.

Finished products are securely packed and shipped via DHL/FedEx/UPS or your preferred method. We support global delivery with full documentation.

Why Choose ADCERAX for Your NBSiC Ceramic Needs?

Choosing the right advanced ceramic supplier is crucial for the success of your industrial projects. ADCERAX stands out as a reliable and competitive partner.

Direct manufacturer eliminating intermediaries for cost-effective solutions without compromising quality.

20+ years of B2B experience providing unparalleled technical support and collaborative design.

Agile manufacturing for small-batch customization and rapid prototyping capabilities.

Stringent quality measures from raw material inspection to final product testing.

24-hour response guarantee with dedicated support for global clientele.

Trusted by global customers for advanced ceramic materials and precision components.

Technical FAQs on ADCERAX® Nitride Bonded Silicon Carbide Ceramic Components

The stability originates from the SiC–Si₃N₄ composite matrix, which resists structural softening even near 1450°C. The nitride-bonded phase reduces creep deformation under constant load. This enables kiln plates and beams to maintain geometry during long-duration firing cycles. Such stability minimizes product warpage in continuous industrial furnaces.

The material exhibits a low creep rate and high modulus retention at elevated temperature. This combination prevents sagging in plates exceeding 800–1200 mm in length. As a result, fired products maintain consistent flatness across the full span. Reduced deformation directly improves firing yield and furnace throughput.

The NBSiC matrix is chemically inert to molten Al and suppresses interfacial reactions. Its dense microstructure limits aluminum infiltration and oxide adhesion. This reduces clogging and stabilizes metal flow in low-pressure casting systems. Enhanced corrosion resistance also lengthens cycle life and lowers replacement frequency.

High flexural strength and exceptionally low creep under load prevent progressive deflection. The bonded nitride phase improves grain boundary stability at temperature. This ensures beams sustain multi-layer kiln loads without dimensional drift. Stable beam geometry protects products from uneven stress distribution during firing.

The composite structure accommodates thermal gradients without internal cracking. Controlled porosity and uniform wall thickness reduce stress concentration during rapid heating and cooling. This design supports 20–30 rapid thermal cycles commonly used in analytical labs. Consistent durability ensures reliable reaction and melting experiments.

Square crucibles use reinforced corner geometry combined with high fracture toughness. The bonded nitride network distributes stress more evenly during thermal expansion. This mitigates crack initiation in the most strain-sensitive zone. The design enables stable performance during large-volume batch reactions.

Its low thermal expansion coefficient limits geometry changes even under steep gradients. High-temperature rigidity maintains wall thickness and flatness in plates and crucibles. Stable dimensions improve process predictability in kilns and reactors. Dimensional control reduces the risk of fixture misalignment and sample contamination.

NBSiC offers greater resistance to oxidation and creep due to its nitride bonding phase. This results in slower degradation during prolonged firing cycles. Higher load-bearing capacity allows thinner and lighter kiln components. These advantages improve furnace energy efficiency and operational stability.

The Si₃N₄ bonding phase forms a protective silica layer when exposed to oxygen. This layer slows further oxidation and prevents structural weakening. Stable oxidation behavior is essential for riser tubes and kiln plates exposed to prolonged airflow. Oxidation resistance contributes directly to extended service life.

Its microstructure provides high flexural strength that remains stable across temperature cycles. Low creep deformation keeps beams from sagging over multi-meter spans. Strong grain bonding enhances resistance to impact and shock loads. These characteristics support dense and heavy firing assemblies.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.

Contact ADCERAX for Your NBSiC Ceramic Solutions

Ready to elevate your industrial applications with high-performance Nitride Bonded Silicon Carbide Ceramic?

Whether you need standard products or custom-engineered solutions, ADCERAX is your trusted partner.

info@adcerax.com

+(86) 0731-74427743 | WhatsApp: +(86) 19311583352

Within 24 hours