Silicon Nitride Parts with Precision, Stability and Long Service Life

ADCERAX manufactures high-performance silicon nitride parts for demanding industrial use. We supply both standard and custom Si₃N₄ parts, including precision silicon nitride rods, durable silicon nitride crucibles for molten metal environments, and high-speed silicon nitride cutting tools for difficult-to-machine alloys.

With controlled materials, accurate machining and consistent quality, our parts deliver stability and long service life. Supported by factory-direct pricing, fast sampling and flexible customization, we help OEMs improve performance and reduce downtime.

🤝Send us your drawings or requirements, and our engineers will recommend the best silicon nitride solution for your application.

What is Silicon Nitride Parts?

Silicon nitride parts are engineered Si₃N₄ components designed to withstand extreme speed, temperature and mechanical stress. With high fracture toughness, low thermal expansion and exceptional wear resistance, they maintain dimensional stability where metals and oxide ceramics fail. These qualities make them essential for bearings, pumps, aluminum casting systems and other demanding industrial equipment.

Silicon Nitride Parts Properties

Silicon nitride (Si₃N₄) parts combine high fracture toughness, low thermal expansion, and exceptional resistance to heat, wear and thermal shock. Their lightweight yet strong microstructure keeps components stable under high speed, high load and extreme temperature cycling, making them ideal for demanding industrial equipment.

Silicon Nitride Parts Technical Sheet

| Si3N4 Type | Gas pressure sintering Si3N4 | Hot pressing sintering Si3N4 | High thermal conductivity Si3N4 |

| Density (g/cm3) | 3.2 | 3.3 | 3.25 |

| Flexture strength (MPa) | 700 | 900 | 600~800 |

| Young Modulus (GPa) | 300 | 300 | 300~320 |

| Poisson’s ratio | 0.25 | 0.28 | 0.25 |

| Compressive strength (MPa) | 2500 | 3000 | 2500 |

| Hardness (GPa) | 15 | 16 | 15 |

| Fracture toughness (MPa*m1/2) | 5~7 | 6~8 | 6~7 |

| Maximum working temperature (℃) | 1100 | 1300 | 1100 |

| Thermal conductivity (W/m*K) | 20 | 25 | 80~100 |

| Thermal expansion coefficient (/℃) | 3*10-6 | 3.1*10-6 | 3*10-6 |

| Thermal shock resistance (ΔT ℃) | 550 | 800 | / |

Advantages of Silicon Nitride Parts

Si₃N₄ parts maintain stiffness and precision under load, ensuring reliable performance in demanding assemblies and critical operations.

They stay structurally stable during rapid temperature changes, making them ideal for high-temperature and thermal-cycling environments.

High hardness and inertness allow Si₃N₄ components to resist abrasion and corrosion in pumps, valves and molten metal systems.

At only ~40% the density of steel, they reduce inertia, heat generation and energy loss in high-speed machinery for improved durability.

Types of Silicon Nitride Part We Supply

ADCERAX provides a wide range of silicon nitride mechanical parts, including rods, crucibles, cutting tools, ignitors, nozzles, ball valve components, hooks, welding rollers and other Si₃N₄ products. All items are produced with consistent quality standards and support both standard models and custom-made designs for diverse industrial requirements.

Si3N4 rods are used in structural supports, precision motion assemblies, furnace fixtures, and other high-temperature industrial systems.

- High strength and rigidity

- Strong thermal shock and wear resistance

- Custom sizes and finishes available

Silicon nitride crucibles are used in molten aluminum handling, alloy melting, and high-temperature sampling.

- Excellent Thermal Shock Resistance

- Non-Wetting & Corrosion Resistant

- High Strength at Elevated Temperatures

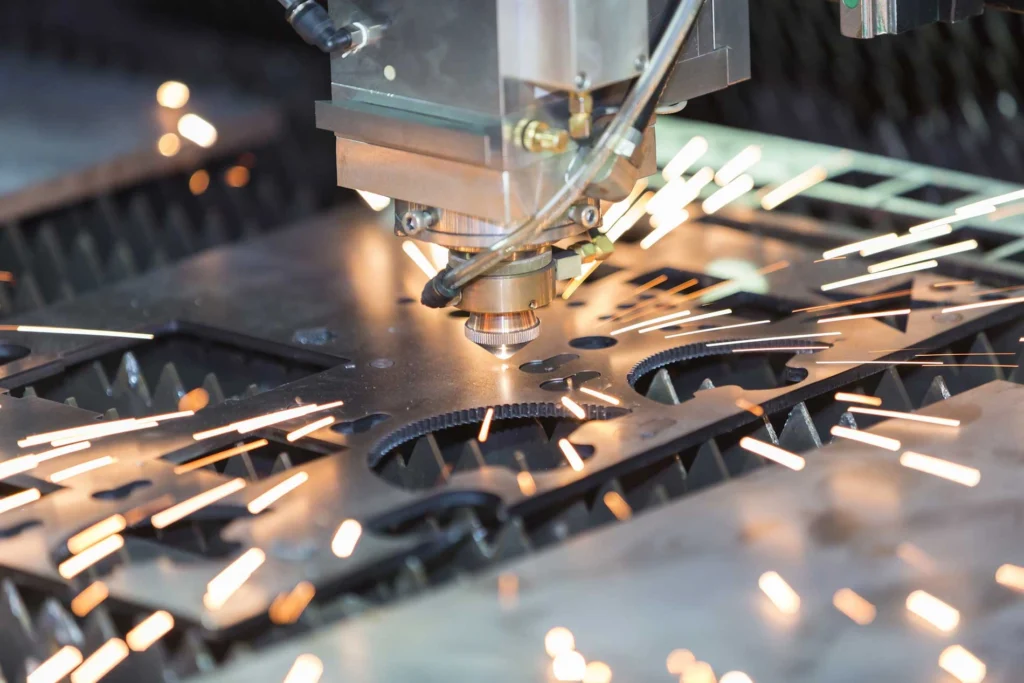

Si3N4 cutting tools are used for high-speed machining of cast iron, nickel alloys, hardened steels and other difficult materials requiring heat resistance.

- High Hot Hardness & Wear Resistance

- Excellent Thermal Shock Resistance

- Longer Tool Life in Difficult Materials

Silicon nitride ignitors are used in gas burners, industrial furnaces, heating systems and combustion units where fast ignition is required.

- Fast & Reliable Ignition

- Excellent Thermal Shock Resistance

- Long Service Life

Silicon nitride nozzles are used in molten metal delivery, die-casting gates, abrasive flow systems and high-temperature spraying.

- Excellent Wear Resistance

- High Thermal Shock Stability

- Non-Wetting & Corrosion Resistant

Silicon nitride ball valves are used in chemical pumps, corrosive fluid systems, high-temperature lines and abrasive media control where low wear,

- High Wear & Impact Resistance

- Excellent Chemical & Temperature Stability

- Long Service Life & Low Maintenance

Silicon nitride ceramic plates are used in high-temperature fixtures, furnace supports, wear panels and precision insulating components.

- High Strength & Thermal Stability

- Excellent Wear & Corrosion Resistance

- Reliable Electrical Insulation

Silicon nitride ceramic hooks are used in high-temperature handling, furnace fixtures, material support systems and corrosive processing lines.

- High Strength Under Heat

- Excellent Wear & Corrosion Resistance

- Stable Performance Under Thermal Cycling

Silicon nitride welding rollers are used in high-temperature welding lines, metal forming systems and material guiding stations.

- Excellent Wear & Heat Resistance

- Low Adhesion to Molten Metal

- High Strength Under Thermal Cycling

🚀Silicon Nitride Parts That Boost Output, Reduce Downtime and Cut Operating Costs.

Engineered for tough environments, our Si₃N₄ components deliver stable performance and extended service life across critical equipment. With precision manufacturing and rapid customization, ADCERAX helps you upgrade equipment efficiency and secure long-term productivity.

Silicon Nitride Parts Applications

Silicon nitride parts are used across mechanical engineering, manufacturing lines, industrial processing equipment, and laboratory systems. They serve in components such as spindles, pumps, bearings, fixtures, furnace tooling, measurement devices, and precision assemblies across a wide range of high-demand industries.

Mechanical Engineering

🧩ADCERAX Solution:

ADCERAX solves these issues with HIP-densified, precision-ground silicon nitride rods, rollers, balls, and wear parts. Tolerances of ±0.01–0.02 mm and Ra ≤ 0.2 μm surfaces ensure stable performance under load, heat, and long operating cycles. Our engineering team supports prototypes, reports, and consistent batch quality for continuous production.

Manufacturing & Production Equipment

🧩ADCERAX Solution:

ADCERAX supplies HIP-densified silicon nitride cutting tools, fixtures, rollers, pins, and wear components with tight tolerances and high fracture toughness. Their thermal stability and low wear rate maintain accuracy in long production runs, reducing tool changes and scrap.

Industrial Machinery & Process Systems

🧩ADCERAX Solution:

ADCERAX provides silicon nitride nozzles, valves, plungers, sleeves, and insulation components engineered for severe conditions. HIP densification, high hardness, and chemical inertness ensure long-term stability against corrosive fluids, abrasive particles, and rapid temperature swings.

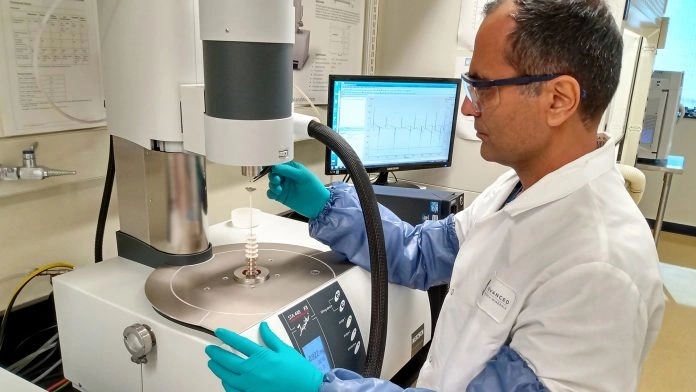

Laboratory & Research Equipment

🧩ADCERAX Solution:

ADCERAX offers high-purity silicon nitride crucibles, plates, pins, probes, and small precision components with excellent chemical stability and minimal thermal expansion. They ensure clean, repeatable results under rapid heating, cooling, or aggressive chemical environments.

Custom Si3N4 Ceramic Parts Manufacturer

ADCERAX specializes in custom silicon nitride parts (Si₃N₄) manufactured according to your drawings, dimensions and structural requirements. We support non-standard shapes, tight tolerances and special machining features for a wide range of industrial components.

Customization Options

Extra-large / Extra-small diameters, non-standard thicknesses, and ultra-long / ultra-short lengths.

Provide higher - level dimensional accuracy and concentricity control than the standard.

Flanges, steps, threads, drilling holes, grooves, etc.

Adjust the material according to the application requirements.

Polish and grind the surface to achieve a specific surface roughness.

Customization Process

Send us your drawing, CAD file, or physical sample with material grade, dimensions, tolerances, and quantity. Our engineers will evaluate the design and provide a detailed quotation with lead time and pricing.

Once the quote is approved, we proceed with sample prototyping (1–50 pcs) if needed, for testing and validation.

After sample approval or direct confirmation, we begin batch manufacturing using CNC machining, sintering, and polishing. All parts undergo dimensional checks, material purity testing, and surface finish inspection.

Finished products are securely packed and shipped via DHL/FedEx/UPS or your preferred method. We support global delivery with full documentation.

High-Performance Silicon Nitride Parts Supplier-ADCERAX

ADCERAX is a silicon nitride ceramic components manufacturer and supplier from China, offering factory-direct pricing, precise machining and fast global delivery. With advanced forming, HIP and grinding capabilities, we ensure consistent quality and reliable performance across a full range of Si₃N₄ components.

Competitive pricing with strict quality control from raw material sourcing to final delivery

Professional team providing comprehensive technical support and collaborative design

Small batch orders to large-scale production with complex geometries and tight tolerances

24-hour response and 24-hour dispatch for standard items, 3-7 weeks for custom orders.

ADCERAX integrates Si3N4 precision parts production, precision machining, HIP sintering and quality inspection into a unified workflow. We supply both standard and custom silicon nitride parts for structural, wear-resistant, and high-temperature applications — from prototypes to mass production.

-

Precision Machining & Dimensional Control

Each silicon nitride component is CNC-machined and ground to meet strict tolerances and surface standards. This ensures stable fit, smooth motion, and reliable performance in demanding mechanical assemblies. -

Batch Consistency & Quality Verification

Every batch is inspected for density, hardness and microstructure uniformity. Controlled HIP and polishing processes maintain consistent part performance and reduce failure rates across diverse applications. -

Customization & Engineering Support

We provide custom Si₃N₄ part solutions based on drawings or samples, supporting non-standard shapes, tight tolerances and special surface finishes. ADCERAX’s engineering team assists with design refinement, material selection and packaging, ensuring fast delivery and dependable global supply.

ADCERAX produces silicon nitride parts (Si₃N₄) using advanced forming, HIP sintering and precision CNC grinding. Each component is built for high strength, tight tolerances and stable performance under load, speed and temperature. We ensure consistent batch quality, smooth surfaces and long service life—making our Si₃N₄ parts reliable for structural, wear-resistant and high-temperature applications.

| Manufacturing Capabilities Overview | |||

|---|---|---|---|

| Capability Item | Typical Value / Description | ||

| Material Grades | Pressureless- or HIP-sintered Si₃N₄ with dense, uniform microstructure. Hardness ≥1500 HV, fracture toughness > 6 MPa·m¹ᐟ², and density ≈ 3.2 g/cm³ — delivering high strength, thermal stability, and wear resistance for demanding ceramic parts. | ||

| Precision Machining | CNC grinding and lapping achieve tight tolerances within ±0.01 mm and flatness ≤0.005 mm. Mirror finishing to Ra ≤0.2 μm ensures smooth contact surfaces, low friction, and stable assembly performance for precision Si₃N₄ components. | ||

| Forming & Shaping | Advanced isostatic pressing and pre-sinter shaping support complex geometries, holes, slots, thin walls, and non-standard features. Suitable for both standard and custom silicon nitride part configurations used across industrial applications. | ||

| Flatness & Dimensional Control | Controlled sintering minimizes porosity and warpage, maintaining consistent dimensions and roundness under mechanical or thermal stress. Ideal for precision-fit structural, sealing, and bearing interfaces. | ||

| Surface Finishing | Precision polishing and ultrasonic cleaning yield defect-free surfaces with uniform roughness and stable contact. Each Si₃N₄ part batch is inspected for density, flatness, and dimensional uniformity to ensure consistent performance. | ||

FAQ

Our silicon nitride parts are made from pressureless-sintered or HIP-sintered Si₃N₄ with dense microstructure, high hardness, excellent thermal stability, and consistent mechanical properties across batches.

Yes. Silicon nitride structural parts are lighter, harder, and more thermally shock-resistant than metals or zirconia, making them ideal for high-speed, high-temperature, and wear-critical applications.

Most Si₃N₄ ceramic parts can be machined to ±0.01 mm, while precision interfaces can reach ±0.005 mm, depending on geometry and thickness.

Yes. We support custom silicon nitride parts, including non-standard dimensions, tight tolerances, complex shapes, blind holes, thin walls, and special surface finishes.

All Si₃N₄ parts undergo density, hardness, dimensional, surface roughness, and microstructure inspections. Additional NDT or customized testing is available upon request.

Most silicon nitride components operate reliably up to 1000°C, depending on design, load, and thermal cycling requirements.

Yes. Many Si₃N₄ components—such as crucibles, nozzles, and riser tubes—offer excellent non-wetting behavior, thermal shock resistance, and chemical stability in molten aluminum or corrosive environments.

Yes. We offer grinding, lapping, and mirror polishing for silicon nitride parts, achieving surface roughness as low as Ra ≤ 0.2 μm for sealing and precision-fit applications.

Standard parts ship within 3–5 days, while custom silicon nitride parts typically require 2–6 weeks, depending on complexity and surface finishing requirements.

Pricing for silicon nitride parts depends on dimensions, tolerances, complexity, and surface finishing. Small parts may cost a few dollars, while precision-machined components can range higher. Send your drawing for an accurate quote within 12 hours.

Absolutely. We provide sample units of silicon nitride parts for sale to support testing, assembly validation, and performance evaluation.

You can purchase silicon nitride parts and silicon nitride wear components directly from ADCERAX, a dedicated manufacturer and supplier in China. We produce custom and standard Si₃N₄ parts—including rods, crucibles, cutting tools, nozzles, plates, valves, and precision wear components—using advanced forming, HIP sintering, and CNC machining.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.

info@adcerax.com

+(86) 0731-74427743 | WhatsApp: +(86) 19311583352

Within 24 hours