Labware Ceramics in Laboratory Applications

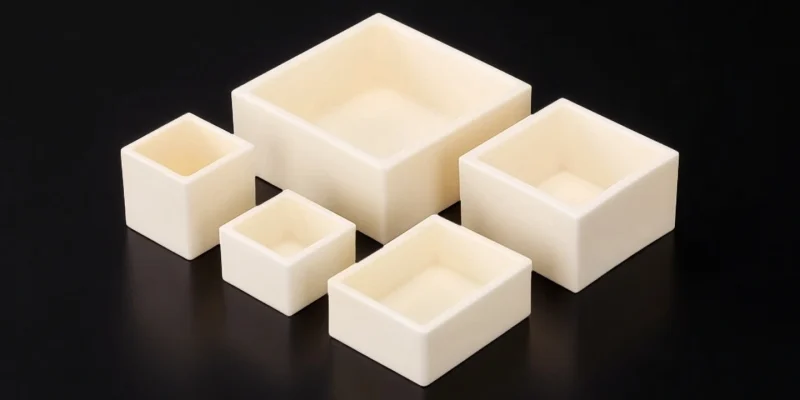

Labware Ceramics are high-temperature and chemically inert components within the broader category of industrial ceramics, designed for crucibles, boats, trays, and grinding tools used in routine and repeated laboratory workflows. In thermal analysis and chemical testing, they minimize contamination and keep the test baseline stable because they release very little volatile residue and remain dimensionally steady.

Compared with metals and glass, ceramic labware stays solid and neutral at elevated temperatures, allowing experiments to remain repeatable across batches. For many laboratories, this industrial-grade stability directly reduces failed runs, instrument downtime, and data deviation.

remains stable across wide laboratory temperature ranges

resists reactions with most laboratory chemicals

maintains reliable insulation under testing conditions

retains strength during repeated laboratory use

Key Properties of ADCERAX® Labware Ceramics

Labware Ceramics used in laboratory environments must perform consistently across thermal electrical chemical and mechanical stress conditions.

Thermal Performance of Laboratory Ceramic Materials

| Thermal Property | Alumina Ceramic (99.7–99.8%) | Zirconia Ceramic (3Y-TZP) | Silicon Carbide Ceramic | Test Conditions |

|---|---|---|---|---|

| Maximum Service Temperature | 1550–1600 °C | 1350–1400 °C | 1600–1650 °C | Air atmosphere, continuous exposure |

| Thermal Conductivity | 20–30 W/m·K | 2–3 W/m·K | 120–200 W/m·K | Measured at 25 °C |

| Thermal Expansion Coefficient | (7.5–8.5)×10⁻⁶ /K | (10–11)×10⁻⁶ /K | (3.8–4.5)×10⁻⁶ /K | 25–1000 °C heating range |

| Thermal Shock Parameter ΔT | 200–250 °C | 250–300 °C | 450–600 °C | Water quench from hot state |

Electrical Performance of Laboratory Ceramic Materials

| Electrical Property | Alumina Ceramic (99.7–99.8%) | Zirconia Ceramic (3Y-TZP) | Silicon Carbide Ceramic | Test Conditions |

|---|---|---|---|---|

| Volume Resistivity | ≥1×10¹² Ω·cm | ≥1×10¹¹ Ω·cm | 10⁻²–10² Ω·cm | DC measurement at 25 °C |

| Dielectric Strength | 15–20 kV/mm | 10–12 kV/mm | — | Oil immersion test |

| Relative Permittivity | 9.5–10.0 | 25–30 | — | 1 MHz, room temperature |

| Electrical Conductivity | ≤1×10⁻¹² S/cm | ≤1×10⁻¹¹ S/cm | 10⁻²–10² S/cm | Room temperature baseline |

Chemical Performance of Laboratory Ceramic Materials

| Chemical Property | Alumina Ceramic (99.7–99.8%) | Zirconia Ceramic (3Y-TZP) | Silicon Carbide Ceramic | Test Conditions |

|---|---|---|---|---|

| Acid Resistance | Stable up to boiling | Stable up to boiling | Stable up to boiling | HCl / H₂SO₄ aqueous solution |

| Alkali Resistance | Stable ≤50 wt% | Stable ≤40 wt% | Stable ≤60 wt% | NaOH / KOH aqueous solution |

| Molten Salt Resistance | ≤900 °C | ≤850 °C | ≤1100 °C | Continuous molten salt exposure |

| Chemical Solubility | <0.01 wt% | <0.02 wt% | <0.005 wt% | 25 °C immersion test |

Mechanical Performance of Laboratory Ceramic Materials

| Mechanical Property | Alumina Ceramic (99.7–99.8%) | Zirconia Ceramic (3Y-TZP) | Silicon Carbide Ceramic | Test Conditions |

|---|---|---|---|---|

| Flexural Strength | 300–400 MPa | 900–1200 MPa | 350–450 MPa | Three-point bending |

| Vickers Hardness | 1500–1800 HV | 1200–1300 HV | 2500–2800 HV | Load 9.8 N |

| Fracture Toughness KIC | 3.5–4.5 MPa·m¹ᐟ² | 7–10 MPa·m¹ᐟ² | 3–4 MPa·m¹ᐟ² | Indentation method |

| Elastic Modulus | 370–390 GPa | 200–210 GPa | 410–450 GPa | Resonance frequency method |

Application Scenarios of ADCERAX® Labware Ceramics

Laboratory ceramics are selected not by shape alone but by how they behave under specific testing and preparation conditions. The following application scenarios reflect how Labware Ceramics are practically used across analytical workflows in industrial and research laboratories.

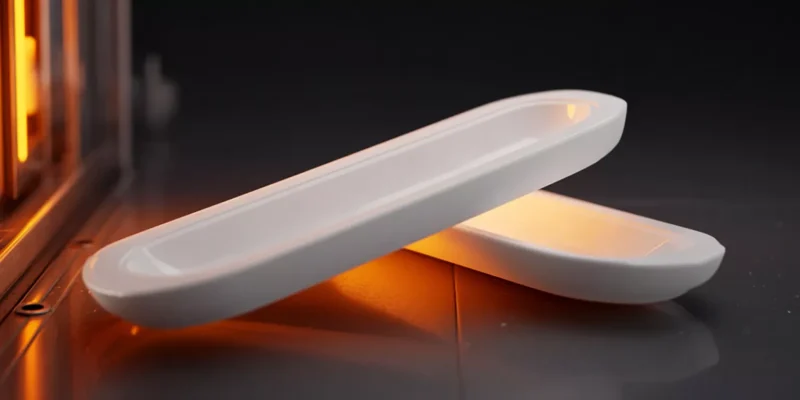

High Temperature Sintering and Material Firing

Sintering and firing processes rely on ceramic supports that maintain geometry and load stability at elevated temperatures.

- Alumina rectangular trays for high temperature use provide flat and stable support surfaces during prolonged firing cycles.

- Alumina round trays for laboratory firing promote even heat exposure and reduce localized thermal stress on samples.

- Alumina and zirconia saggars protect materials from direct furnace exposure while preserving dimensional accuracy.

Ash Content and Elemental AnalysisAsh Content and Elemental Analysis

Combustion and ash testing require ceramic ware that introduces no contaminants and withstands repeated high-temperature oxidation cycles.

- Alumina combustion boats for ash tests allow clean sample combustion without contributing foreign residues to ash results.

- High purity alumina crucibles reduce trace element interference and improve reliability in elemental composition analysis.

- Laboratory Ceramic Ware for elemental analysis maintains chemical neutrality during repeated oxidation and cooling stages.

Chemical Reaction and Corrosive Testing

Aggressive chemical environments require ceramics with strong corrosion resistance and high thermal shock tolerance.

- Silicon carbide crucibles for laboratory use withstand corrosive media while maintaining structural integrity at high temperatures.

- Thermal shock resistant SiC crucibles support rapid heating and cooling cycles without cracking or deformation.

- Ceramic lab equipment for chemical analysis provides long-term stability in reactive or oxidizing test environments.

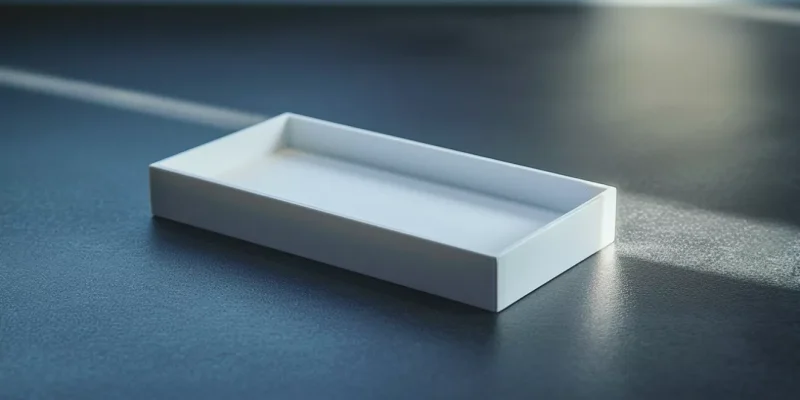

Thermal Analysis and Heat Flow Measurement

In thermal analysis systems, ceramic components must remain inert and dimensionally stable to avoid baseline distortion and signal drift.

- Alumina crucibles for TGA analysis provide stable thermal behavior and prevent container-induced signal interference during heating cycles.

- Alumina sample pans for DSC analysis ensure uniform heat transfer while minimizing background noise in sensitive heat flow measurements.

- Low background ceramic labware components help isolate true sample responses by avoiding parasitic reactions at elevated temperatures.

Sample Preparation and Mechanical Grinding

Sample preparation demands wear-resistant ceramics that minimize particle contamination during crushing and milling.

- Alumina mortar and pestle sets enable controlled manual grinding without introducing metallic impurities into samples.

- Zirconia mortar and pestle sets offer enhanced wear resistance for hard or abrasive materials during repeated use.

- Alumina grinding jars for laboratory milling support consistent particle size reduction with low material shedding.

Choose Labware Ceramics That Fit Your Test Conditions

Different laboratory processes demand different ceramic shapes and material behaviors. ADCERAX® Labware Ceramics are selected based on temperature exposure chemical environment and handling frequency.

Standard Types of ADCERAX® Labware Ceramics

In laboratory systems different ceramic form factors are selected based on temperature range chemical exposure and mechanical stress requirements across testing workflows.

Alumina Crucibles

Alumina crucibles are the most widely used Laboratory Ceramic Ware for thermal analysis and routine high-temperature testing.

- Stable baseline for thermal analysis

- High purity minimizes sample contamination

- Wide size compatibility with instruments

Zirconia Crucibles

Zirconia crucibles are selected when mechanical strength and wear resistance are critical in ceramic labware applications.

- High fracture toughness for repeated handling

- Excellent wear resistance in sample preparation

- Suitable for aggressive grinding environments

Silicon Carbide Crucibles

Silicon carbide crucibles are preferred ceramic lab equipment for extreme thermal shock and corrosive laboratory conditions.

- Exceptional thermal shock resistance

- High thermal conductivity for rapid heating

- Reliable performance in corrosive conditions

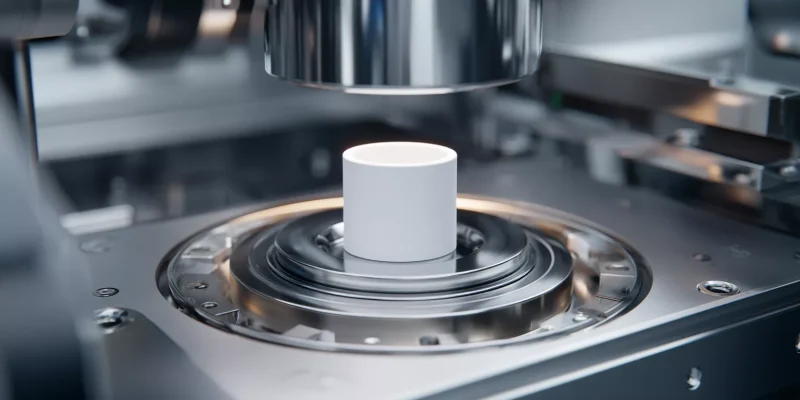

One Stop Processing Services for Labware Ceramics

ADCERAX® provides a single, integrated workflow for metallurgical ceramic components, covering every stage from material selection to final delivery.

This one-stop approach reduces coordination risk and ensures metallurgical ceramics remain consistent with real operating conditions rather than isolated specifications.

Alumina, Zirconia and SiC Ceramics

controlled pressing within ±0.5%

shape accuracy before sintering stage

stable sintering up to 1600 °C

dimensional tolerance within ±0.05 mm

batch checks with traceable records

Advanced Manufacturing Processes for ADCERAX® Labware Ceramics

Precision Powder Forming

Uniform powder forming defines density distribution and directly influences shrinkage behavior during firing.

pressure control within ±0.5 percent

density variation below 1%

repeat geometry across production batches

High Temperature Sintering Control

Sintering stability determines grain structure and long term thermal reliability of ceramic labware.

stable firing up to 1600 °C

furnace gradient below ±5 °C

repeatable shrinkage across multiple batches

Precision CNC Finishing

Final machining ensures dimensional compatibility with analytical instruments and fixtures.

dimensional tolerance within ±0.05 mm

Ra values down to 0.8 μm

reduced chipping during laboratory handling

Custom Labware Ceramics Built for Your Experiments

ADCERAX® provides laboratory ceramic customization that aligns geometry material behavior and process stability with real testing conditions.

Each custom solution is engineered to reduce experimental deviation and improve long term repeatability across laboratory workflows.

Contact ADCERAX® to align your labware ceramics with your instrument and test protocol.

Engineering Answers to Real Labware Ceramics Challenges from ADCERAX®

Baseline drift is often caused by impurity release or unstable heat capacity during heating cycles. High-purity Labware Ceramics from ADCERAX® minimize volatile residues and maintain predictable thermal behavior. This stability ensures the instrument records only the sample response, not interference from the container.

Lower-purity alumina can introduce trace oxides that alter heat flow signals at elevated temperatures. ADCERAX® Labware Ceramics use controlled purity ranges up to 99.8%, reducing parasitic reactions. This improves repeatability in DSC and TGA measurements over long test sequences.

Cracking typically results from uneven density or uncontrolled thermal gradients. ADCERAX® Labware Ceramics are formed with uniform green density and fired under controlled kiln profiles. This reduces internal stress and improves resistance to rapid temperature changes.

Dimensional mismatch is often due to inconsistent shrinkage during sintering. ADCERAX® controls forming pressure and firing cycles to keep shrinkage predictable. As a result, Labware Ceramics fit instrument holders reliably without secondary adjustment.

Rough ceramic surfaces trap residues that are difficult to remove between tests. ADCERAX® Labware Ceramics are precision-finished to low Ra values, improving cleanability. This reduces cross-contamination and shortens preparation time between experiments.

Metals can oxidize or react with samples at elevated temperatures. Labware Ceramics remain chemically inert and structurally stable well above 1000 °C. This prevents sample contamination and extends usable service life.

Zirconia offers higher fracture toughness and wear resistance than alumina. ADCERAX® zirconia Labware Ceramics maintain smooth surfaces even after repeated grinding cycles. This reduces particle contamination in sensitive material analysis.

Silicon carbide combines high thermal conductivity with strong corrosion resistance. ADCERAX® SiC Labware Ceramics withstand rapid heating and chemically aggressive atmospheres. This makes them ideal for harsh chemical reaction validation.

Deformation is usually caused by insufficient high-temperature mechanical strength. ADCERAX® Labware Ceramics maintain shape stability through optimized firing and controlled grain structure. This preserves consistent sample geometry during ash analysis.

Inconsistent wall thickness leads to uneven heat distribution. ADCERAX® controls forming and machining to maintain uniform section thickness. This results in predictable thermal response during heating and cooling cycles.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.