Industrial-Grade Silicon Carbide Mechanical Components Built for Harsh Processes by ADCERAX®

Silicon Carbide Mechanical Components provide stable mechanical strength, controlled thermal behavior, and corrosion resistance required in aggressive industrial conditions.

Their performance supports consistent operation across demanding fluid, thermal, and structural environments to reduce downtime and maintenance cycles.

Accelerate your material upgrade journey with ADCERAX® and request an engineering-supported quotation today.

±0.02 mm

Precision Tolerance

Introduction to Silicon Carbide Mechanical Components

Silicon Carbide Mechanical Components are engineered for industrial systems exposed to corrosive media, abrasive slurries, heavy mechanical loading, and rapid thermal fluctuations. Their microstructure enables dimensional stability and long-term durability in equipment where metal or oxide ceramics frequently fail.

These components function as abrasion-resistant flow liners in slurry pipelines, precision load-bearing elements in rotating pump assemblies, corrosion-proof sealing interfaces in aggressive chemical circuits, and thermally stable porous structures in high-temperature filtration systems, ensuring predictable service life under harsh industrial operating conditions.

Applications extend across chemical processing, mining, metallurgy, thermal plants, environmental treatment, and other continuous-operation manufacturing environments.

Technical Specification of Silicon Carbide Mechanical Components

Silicon Carbide Mechanical Components are defined by a set of physical, mechanical, and thermal parameters that determine their suitability for corrosive, abrasive, and high-temperature industrial environments.

| Technical Specification Table | ||

|---|---|---|

| Parameter | Technical Values / Conditions | |

| Material System | Reaction-Bonded SiC (RBSiC) / Sintered SiC (SSiC) | |

| Density (g/cm³) | RBSiC: 2.95–3.05 SSiC: 3.10–3.16 | |

| Flexural Strength (MPa) | RBSiC: 250–350 SSiC: 350–450 | |

| Hardness (GPa) | 22–27 GPa | |

| Thermal Conductivity (W/m·K) | RBSiC: 90–140 SSiC: 120–160 | |

| Thermal Expansion (CTE) | 4.0–4.5 ×10⁻⁶ /K (25–1000°C) | |

| Maximum Service Temperature | RBSiC: 1350–1450°C SSiC: 1600–1700°C | |

Key Properties of ADCERAX® Silicon Carbide Mechanical Components

The performance of Silicon Carbide Mechanical Components is defined by their controlled microstructure, engineered porosity, and high-purity SiC matrix stability under chemical, mechanical, and thermal loading.

Chemical Stability & Corrosion Resistance

Silicon carbide maintains chemical inertness and structural integrity across corrosive industrial media due to its dense and minimally absorbent matrix.

- Absorption controlled below 0.02% level

- Porosity stabilized under 0.1% threshold

- Density maintained near 3.16 g/cm³

- Chemical degradation minimized in acid systems

Mechanical Strength & Wear Performance

Mechanical reliability arises from high strength, dimensional stability, and abrasion resistance under continuous mechanical loading.

- Flexural strength reaching 450 MPa

- Compressive strength exceeding 2200 MPa

- Hardness sustained at 27 GPa levels

- Wear rate limited to 1×10⁻⁶ loss

Thermal Shock & High-Temperature Behavior

Thermal stability is governed by low expansion, high conductivity, and resistance to rapid temperature fluctuation.

- Expansion controlled at 4.0×10⁻⁶/K

- Conductivity achieved at 160 W/m·K

- Thermal cycling tolerance near 300°C gradients

- Service temperature reaching 1700°C capability

Controlled Porosity & Functional Microstructures

Functional microstructures offer permeability, filtration accuracy, and thermal stability across porous SiC applications.

- Pore density adjustable to 60 PPI

- Honeycomb structure reaching 400 cpsi

- Gas permeability measured 2.5×10⁻¹² m²

- Filtration temperature sustained at 1500°C

ADCERAX® Silicon Carbide Mechanical Components Showcase

Slurry Transport Protection

Silicon carbide liner structures operate in abrasive slurry, corrosive gas, and particulate-rich pipelines where metallic systems degrade rapidly. Their wear-resistant behavior increases service cycles and reduces unplanned shutdowns in mining, chemical, desulfurization, and metallurgical applications.

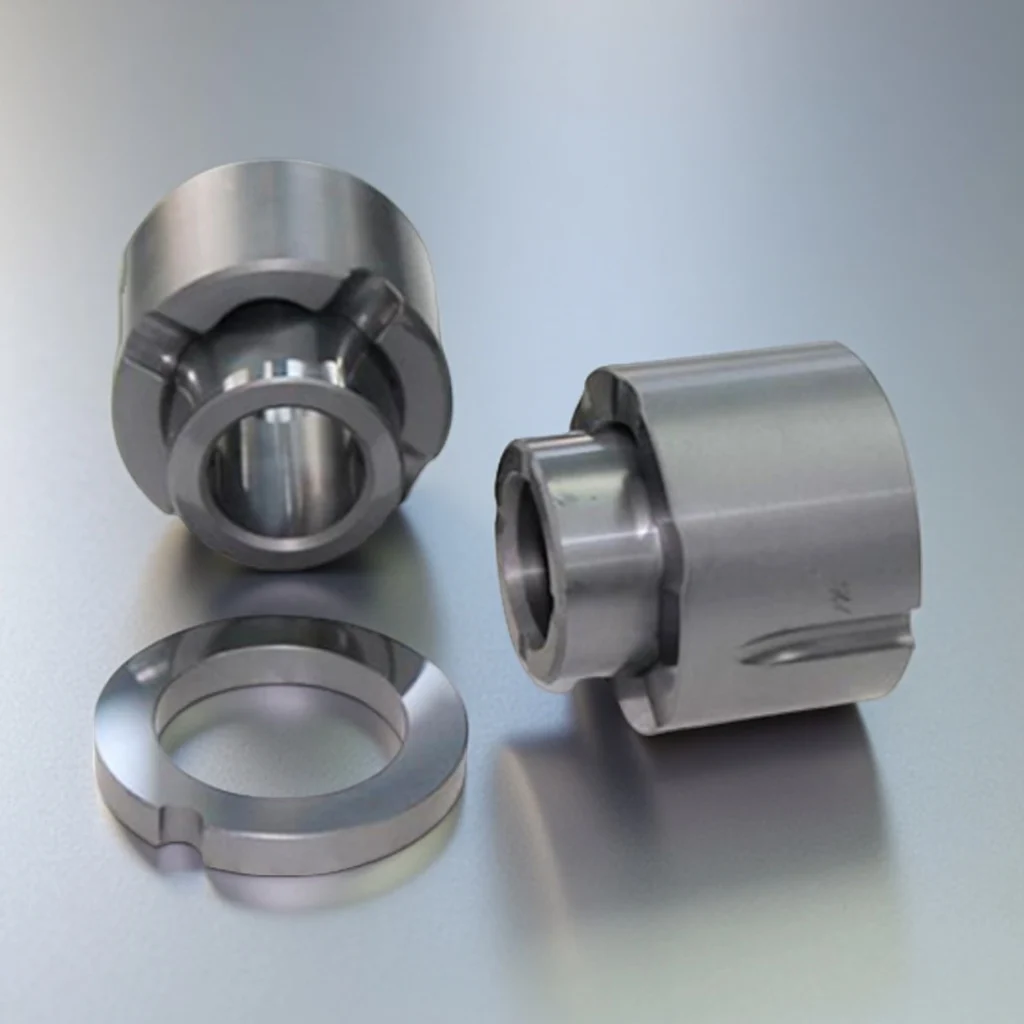

Rotational Load Support

Silicon carbide bearing components sustain rotating loads, maintain lubrication clearance, and ensure geometric stability under corrosive chemical environments. Their precision capability supports shaft systems in chemical pumps, magnetic-drive units, mixers, and reactors requiring ±0.02–0.05 mm dimensional consistency.

Corrosion-Proof Sealing

Silicon carbide sealing structures prevent leakage and maintain operational continuity in aggressive fluid-control environments where metal components fail by pitting or erosion. Their corrosion-resistant surfaces extend sealing life in hydrometallurgy, chemical circuits, and high-load valve assemblies.

High-Temperature Filtration

Silicon carbide porous structures deliver stable performance in molten-metal handling, exhaust treatment, and precious-metal refining processes. Their thermal and chemical robustness minimizes inclusions, ensures catalytic uniformity, and prevents filtration instability that elevates defect rates.

Interested in Partnering with ADCERAX® for Your Next Project?

ADCERAX® provides material guidance, design evaluation, and application-focused support for engineering programs requiring Silicon Carbide Mechanical Components.

Reliable solutions, clear technical communication, and stable delivery performance are offered to help strengthen project execution and ensure dependable system operation.

Key Applications of Silicon Carbide Mechanical Components

Silicon Carbide Mechanical Components are essential in a wide range of industrial applications, offering superior performance in demanding environments. Their exceptional durability and resistance to wear and corrosion make them ideal for high-temperature, high-pressure, and abrasive conditions.

Advanced Solutions for Slurry Transport

Silicon carbide liner components maintain structural performance in high-solids slurry systems where abrasive particles continuously erode metallic surfaces. Their dense microstructure and low porosity reduce material removal even under turbulent flow regimes. Stable wear behavior enables long-duration operation in mining, desulfurization, and mineral-processing pipelines.

- Abrasive particles accelerated above 20 m/s impact surfaces

- Porosity controlled below 0.1% enhances erosion resistance

- Hardness maintained at 27 GPa reduces mechanical removal

Precision Components for Rotating Systems

Silicon carbide bearing and shaft elements withstand continuous rotational loading in environments involving corrosive chemicals and elevated temperatures. Their dimensional accuracy preserves stable lubrication gaps and prevents shaft misalignment. These characteristics support long-term reliability in chemical pumps, magnetic-drive units, and reactor mixers.

- Dimensional precision maintained at ±0.02–0.05 mm tolerance

- Compressive strength exceeding 2200 MPa resists deformation loads

- Thermal conductivity near 160 W/m·K stabilizes temperature rise

Reliable Structures for Chemical Sealing

Silicon carbide sealing structures provide stable operation in systems transporting acidic, alkaline, or oxidizing fluids. Their chemically inert surfaces prevent pitting, erosion, and surface-weakening reactions that occur rapidly in metallic components. Long-term sealing stability supports continuous operation of hydrometallurgy and chemical-regulation systems.

- Absorption minimized below 0.02% ensures sealing reliability

- Density maintained at 3.16 g/cm³ reduces chemical ingress

- Hardness reaching 27 GPa improves surface durability

Enhanced Media for Thermal Filtration

Silicon carbide porous structures maintain filtration accuracy in extreme-temperature environments involving molten metals, exhaust gases, or catalytic reactions. Their thermal and chemical robustness reduces structural deformation during rapid temperature shifts. Consistent pore geometry supports predictable flow performance across demanding industrial processes.

- Filtration stability maintained from 600–1500°C operation range

- Pore density adjustable up to 60 PPI precision

- Honeycomb structure reaching 400 cpsi improves flow uniformity

SiC Mechanical Components One-Stop Custom Supply by ADCERAX®

Integrated Customization Capability for Silicon Carbide Complex Components

A fully integrated workflow for Silicon Carbide Mechanical Components enables stable material selection, tolerance prediction, and manufacturability verification before machining begins. This holistic approach reduces rework risk, improves dimensional repeatability, and aligns each component with long-term operational reliability.

Engineering consultation from ADCERAX® is available for demanding component development.

-

Geometric Feasibility Mapping:

Complex shapes are validated for manufacturability stability. -

Tolerance Stability Planning:

Dimensional limits are aligned with process capability ranges. -

Material Behavior Assessment:

Thermal and mechanical responses are reviewed before machining. -

Sequential Process Control:

Each machining stage follows controlled parameter windows. -

Surface Integrity Review:

Roughness and defect levels are checked against standards. -

Batch Variation Control:

Dimensional consistency is confirmed across repeated production lots.

Manufacturing Strength for Silicon Carbide Mechanical Components

A dedicated production system for Silicon Carbide Mechanical Components supports stable machining accuracy, multi-stage forming capability, and consistent batch performance across complex geometries. Equipment capacity, precision metrics, and controlled process windows ensure repeatable quality for both standard and custom-designed SiC parts.

| Manufacturing Capabilities Overview | |||

|---|---|---|---|

| Manufacturing Process Item | Technical Capability / Data Indicator | ||

| Multi-axis CNC machining centers | 4–5 axis configuration supporting ±0.02 mm accuracy | ||

| Diamond grinding & polishing lines | Ra 0.1–0.4 µm achievable on sealing surfaces | ||

| High-precision drilling systems | Hole concentricity maintained within 0.03 mm | ||

| Large-format sintering furnaces | Max load capacity 800–1200 kg per batch | ||

| RBSiC / SSiC forming equipment | Complex shapes up to 650 mm dimension envelope | ||

| Automated dimensional inspection (CMM) | Measurement repeatability ≤ 0.005 mm | ||

| Profilometer (optical & contact) | Surface profile traceability up to 0.001 mm resolution | ||

| Batch-stability process controls | Dimensional variation maintained below 1.5% across batches | ||

customized Silicon Carbide Mechanical Components supplier

We specialize in custom SiC mechanical components with special sizes, tight tolerances, and complex features. OEM and small-batch support available.

Customization Options

Extra-large / Extra-small diameters, non-standard thicknesses, and ultra-long / ultra-short lengths.

Provide higher - level dimensional accuracy and concentricity control than the standard.

Flanges, steps, threads, drilling holes, grooves, etc.

Adjust the material according to the application requirements.

Polish and grind the surface to achieve a specific surface roughness.

Customization Process

Send us your drawing, CAD file, or physical sample with material grade, dimensions, tolerances, and quantity. Our engineers will evaluate the design and provide a detailed quotation with lead time and pricing.

Once the quote is approved, we proceed with sample prototyping (1–50 pcs) if needed, for testing and validation.

After sample approval or direct confirmation, we begin batch manufacturing using CNC machining, sintering, and polishing. All parts undergo dimensional checks, material purity testing, and surface finish inspection.

Finished products are securely packed and shipped via DHL/FedEx/UPS or your preferred method. We support global delivery with full documentation.

FAQs About Silicon Carbide Mechanical Components by ADCERAX®

Silicon Carbide Mechanical Components exhibit extremely low wear rates under high loading, enabling longer operational windows compared with metallic liners. Their hardness and rigid microstructure prevent early wall thinning in slurry pipes, cyclone liners, and pump chambers. This stability reduces the frequency of shutdowns and helps maintain predictable performance in slurry transport systems.

The rigid lattice structure of silicon carbide minimizes deformation under radial and axial loads, making it suitable for bearings, shaft sleeves, and thrust rings. Dimensional drift remains minimal even when exposed to repeated thermal cycles and continuous rotation. This ensures consistent lubrication gaps and reduces the risk of premature bearing seizure.

Silicon carbide is chemically inert to strong acids, alkalis, and chloride-rich fluids, ensuring long-term integrity in valves, mechanical sealing rings, and reaction-line fittings. Its corrosion resistance remains stable even at elevated temperatures. This durability helps prevent leakage, pitting failure, and unexpected equipment downtime.

The fine grinding capability of silicon carbide delivers extremely flat sealing surfaces, reducing leakage risk under high pressure. ADCERAX® components maintain surface integrity even after thousands of open–close cycles. This results in improved sealing reliability for ball valves, sealing rings, and precision fastening elements.

Silicon carbide preserves strength at elevated temperatures and exhibits low thermal expansion, reducing structural distortion under rapid heating. This makes it ideal for igniters, thermal plates, and hot-zone supports. The material’s thermal shock resistance lowers fracture risk during repeated heating cycles.

The stable multi-porous morphology of SiC foam filters and honeycomb ceramics supports consistent flow distribution and impurity capture. Their structural rigidity prevents pore collapse under high thermal loads. This uniformity contributes to cleaner casts, more effective catalytic reactions, and longer filtration intervals.

The high hardness and abrasion resistance of silicon carbide restrict particle embedding and micro-groove formation. This results in slower dimensional loss in liner tubes, cone liners, and pump chambers. Consequently, equipment maintenance intervals extend significantly in mining and chemical slurry operations.

Precision CNC machining and multi-stage metrology checks maintain strict tolerance windows during production. Dimensional variations are monitored continuously to ensure batch repeatability. Customers receive components with performance uniformity suitable for OEM and long-term maintenance programs.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.

Partner with ADCERAX for Precision SiC Mechanical Components

Looking for a reliable silicon carbide mechanical components supplier? Let us help you with your next project.

info@adcerax.com

Tel.:

+(86) 0731-74427743

WhatsApp:

+(86)19311583352

Within 24 hours