Ceramic Parts & Components That Outlast Metal in Harsh Service

ADCERAX is a ceramic parts manufacturers in China, supplying alumina, zirconia, and silicon carbide components for wear, heat, and corrosion-critical assemblies. Core products include ceramic wear parts, ceramic insulation parts, precision ceramic parts, and ceramic pump parts, built to address abrasion loss, chemical attack, thermal distortion, and electrical isolation failures that shorten service life in industrial equipment.

With fast engineering-to-drawing support, flexible prototyping to repeat supply, and inspection-backed consistency, ADCERAX helps buyers reduce downtime risk while keeping lead times and total cost predictable.

What is a Ceramic Parts

Ceramic components are functional, engineered parts made from technical ceramics that serve a defined role within an assembly—such as wear control, electrical insulation, sealing interfaces, or dimensional stability under heat and chemicals.

In engineering usage, ceramic parts are specified by system-level function and performance requirements (duty conditions, tolerances, surface finish, and material grade) to ensure reliable, repeatable operation in industrial equipment.

Ceramic Parts & Component Properties

Precision ceramic parts deliver stable performance where metals drift or wear. High hardness and low wear support longer service life, while heat and chemical resistance reduce deformation and corrosion in harsh duty.

Alumina Ceramic Parts

Alumina ceramic parts combine high hardness, strong wear resistance, and reliable electrical insulation. They stay dimensionally stable in hot, corrosive environments, so they work well as general industrial wear and insulation components.

| Property | Unit | 99% Al₂O₃ | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

|---|---|---|---|---|---|---|---|---|

| Alumina content | % | 99 | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.88 | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Flexural strength | MPa | 360 | 379 | 312 | 313 | 314 | 315 | 320 |

| Hardness | GPa | 13.5 | 14.1 | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 30–35 | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | 200 | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1700 | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.2 | 8.4 | – | – | – | – | – |

| Melting point | °C | ≈2050 | ≈2050 | ≈2050 | ≈2050 | ≈2050 | ≈2050 | ≈2050 |

Zirconia Ceramic Parts

Zirconia ceramic parts offer very high strength and fracture toughness compared with most ceramics. They keep smooth, low-wear surfaces under load, making them ideal for precision structural, screw and sealing elements.

| Property | Specification |

| Maximum Working Temperature | 1500 °C continuous use |

| Density | 5.65 g/cm³ |

| Thermal Expansion Coefficient | 10.3 × 10⁻⁶/K (25–1000 °C) |

| Thermal Conductivity | 2.2 W/m·K at 1000 °C |

| Chemical Stability | 0.08% mass loss after 24 h acid/alkali exposure at 1200 °C |

| Flexural Strength | 900 MPa at room temperature |

| Fracture Toughness | 8 MPa·m½ |

| Hardness (Vickers) | 12 GPa |

| Elastic Modulus | 210 GPa |

Silicon Carbide Ceramic Parts

Silicon carbide ceramic parts provide extreme abrasion resistance, high thermal conductivity, and excellent chemical stability at high temperature. They are preferred for nozzles, seal faces, and other parts exposed to hot, fast-moving, or abrasive media.

| Property | Specification |

|---|---|

| Material System | RBSiC (80% SiC, 20% free Si) / SSiC (≥99% SiC) |

| Maximum Operating Temperature | ≤1380°C (RBSiC) / ≤1600°C (SSiC) |

| Bulk Density | 3.02 g/cm³ (RBSiC) / 3.10 g/cm³ (SSiC) |

| Open Porosity | <0.1% |

| Flexural Strength (20°C) | 250 MPa (RBSiC) / 380 MPa (SSiC) |

| Flexural Strength (1200°C) | 280 MPa (RBSiC) / 400 MPa (SSiC) |

| Compressive Strength | 1000–2200 MPa |

| Elastic Modulus | 330 GPa (RBSiC) / 420 GPa (SSiC) |

| Thermal Conductivity | 45 W/m·K (RBSiC) / 74 W/m·K (SSiC) |

| Thermal Expansion Coefficient | 4.1–4.5 ×10⁻⁶/K |

| Hardness | 2600–2800 kg/mm² |

| Chemical Stability Range | pH 2–12 |

| Oxidation Stability | <1% microstructural oxidation after 50 cycles (1000°C → RT) |

Silicon Nitride Ceramic Parts

Silicon nitride ceramic parts offer high strength, low density, and excellent thermal-shock resistance. They suit high-speed, high-temperature equipment where weight reduction and efficient heat dissipation are critical.

| Property | Description | Notes |

|---|---|---|

| Density | ≈ 3.2 g/cm³ | About 60% lighter than bearing steel, reducing centrifugal force at high speed |

| Hardness | ≈ 1,500 – 1,700 HV | High surface hardness limits indentation and slows wear under rolling contact. |

| Elastic Modulus | ≈ 300 – 320 GPa | Maintains stiffness under load, supporting stable geometry at high RPM. |

| Thermal Expansion Coefficient | ≈ 3.0 × 10⁻⁶ /K | Much lower than steel, helping control preload and internal clearance as temperature changes. |

| Thermal Shock Resistance | High | Handles rapid temperature changes with lower cracking risk. |

| Electrical Insulation | Excellent (non-conductive) | Effectively blocks electrical discharge damage (EDM) in VFD-driven motors. |

| Corrosion Resistance | Excellent in most acids, alkalis, and humid environments | Resists rust, pitting, and chemical attack that degrade steel. |

Precision Ceramic Part Products & Types

Explore our main precision ceramic part families by material and use. From alumina and zirconia to SiC and Si₃N₄, these examples show typical screws, bushings, spacers, fixtures, nozzles and other wear or insulating parts that can be adapted to your own designs.

Alumina ceramic parts

Go-to option for cost-effective insulating parts in furnaces, kilns and lab equipment—keep fixtures clean, stable and easy to replace.

zirconia ceramic parts

Chosen for compact mechanisms that see high load or impact—precision guides, bushes and wear inserts that must stay tight and run longer.

Silicon Nitride Parts

Preferred in high-speed or thermal-shock service—rotor parts, rollers and tooling where lower mass and long service life cut downtime.

zTA ceramic components

Best suited to abrasive slurries, hot gas and corrosive liquids—nozzles, seal faces and flow components that need stable clearance in harsh media.

silicon carbide ceramic parts

Good choice for slurry pumps, burners and kiln hardware—keep clearances stable in abrasive, high-load process lines.

aluminum nitride ceramic parts

Go-to option for heat-focused electronics and fixtures—support compact layouts where fast heat spreading keeps devices safe.

Boron Nitride Ceramic Parts

Ideal for vacuum, molten metal and inert-gas tooling—make release plates, nozzles and shields that simplify clean changeovers.

Metalized Ceramics Parts

Used for hermetic feedthroughs, sensor housings and power modules—join reliably to metal hardware while keeping circuits protected.

Industrial Ceramic Parts

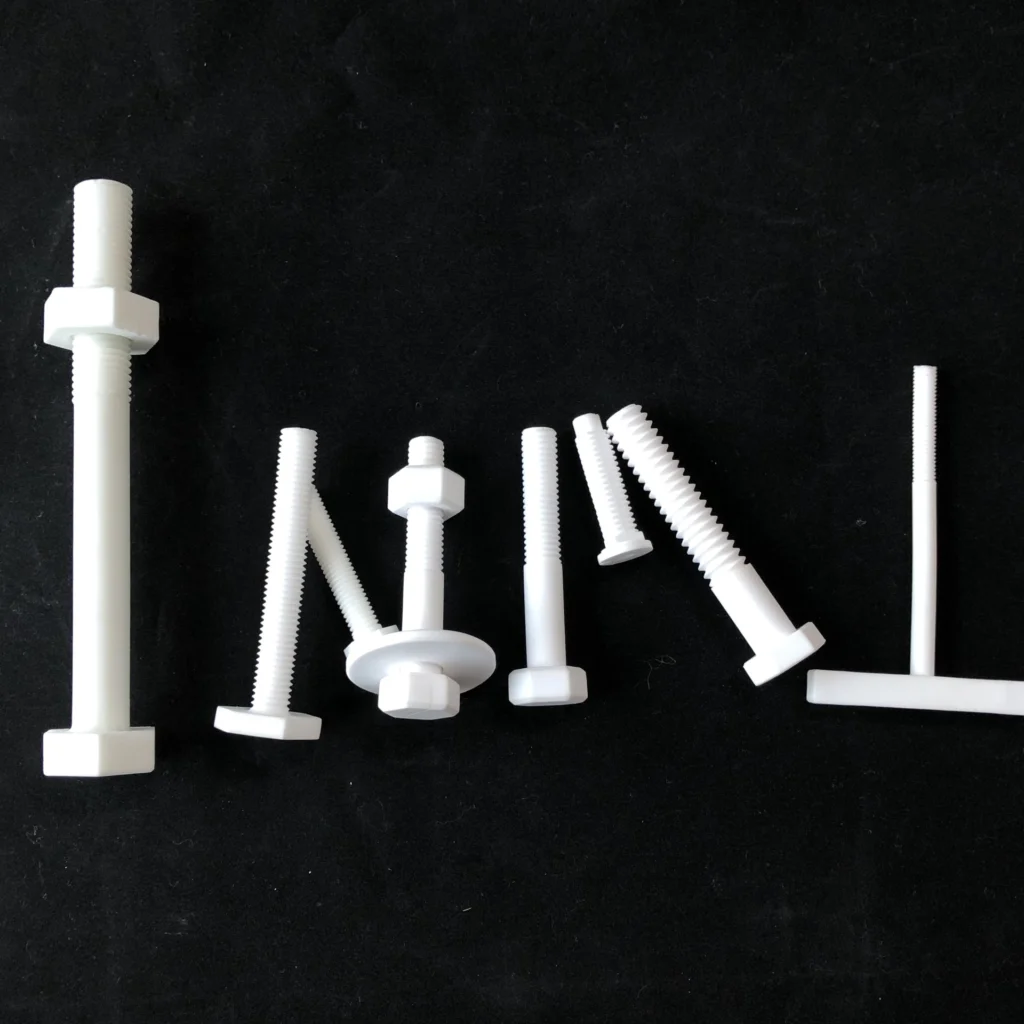

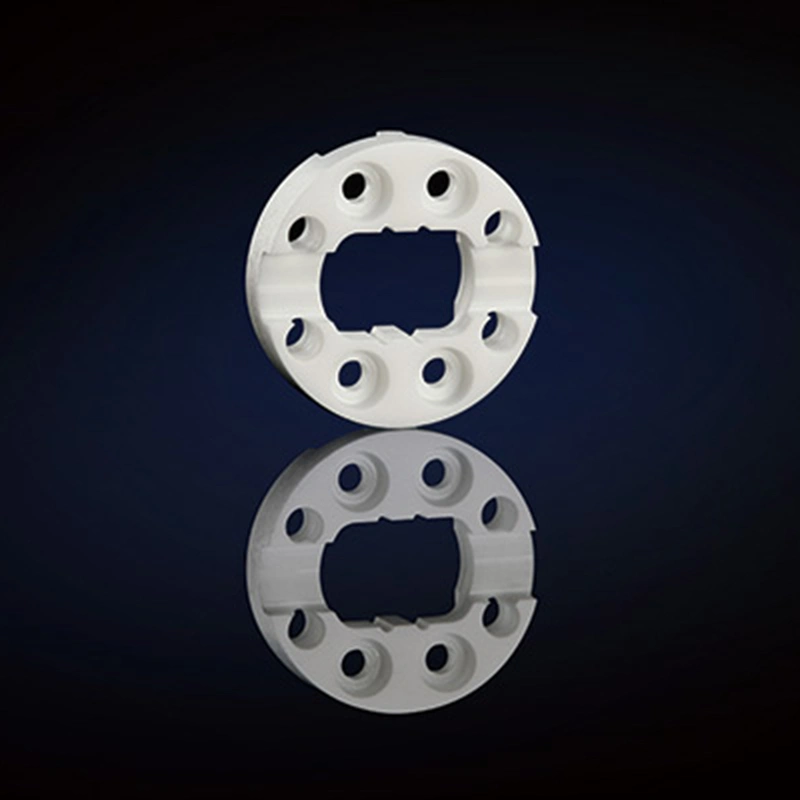

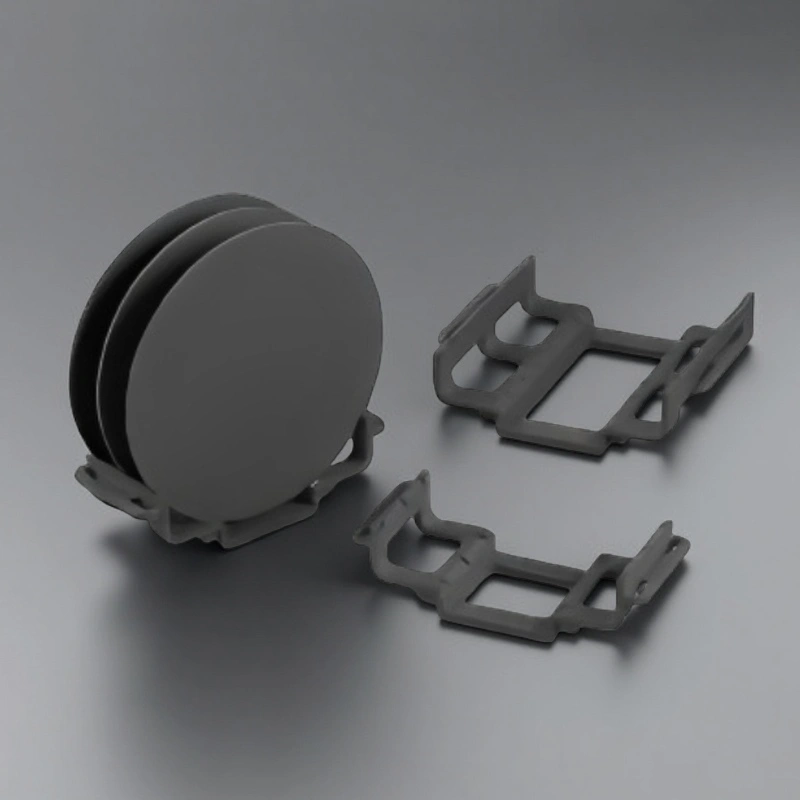

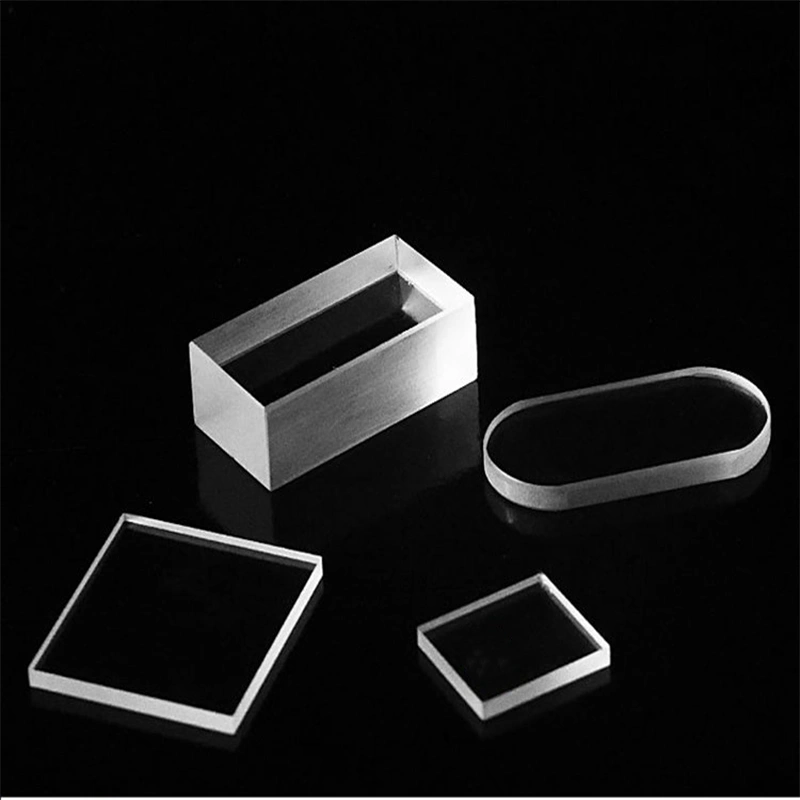

Industrial ceramic components are precision-machined components made from technical ceramics, offering high wear resistance, thermal stability, and electrical insulation. Available in nozzles, kiln plates, screw with nut, beam,hook and custom structures.

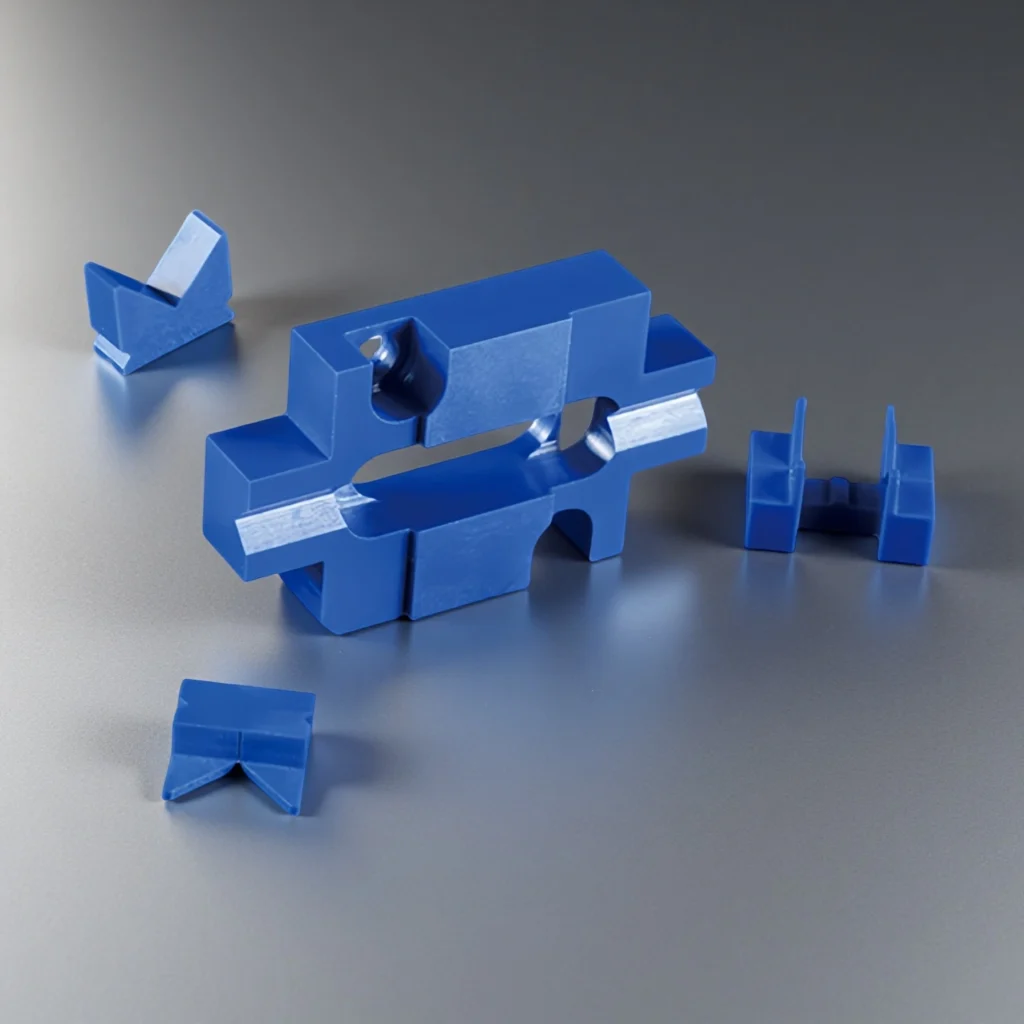

Ceramic Machine Parts

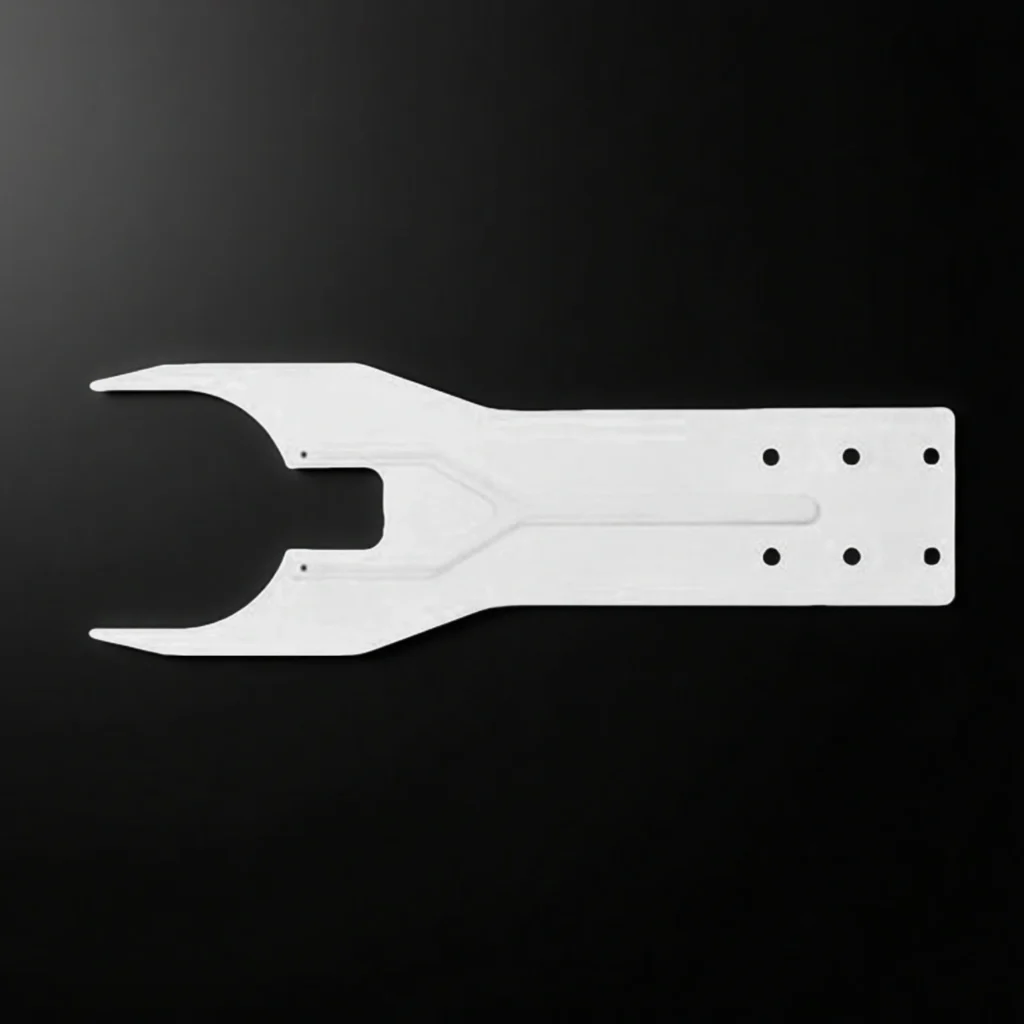

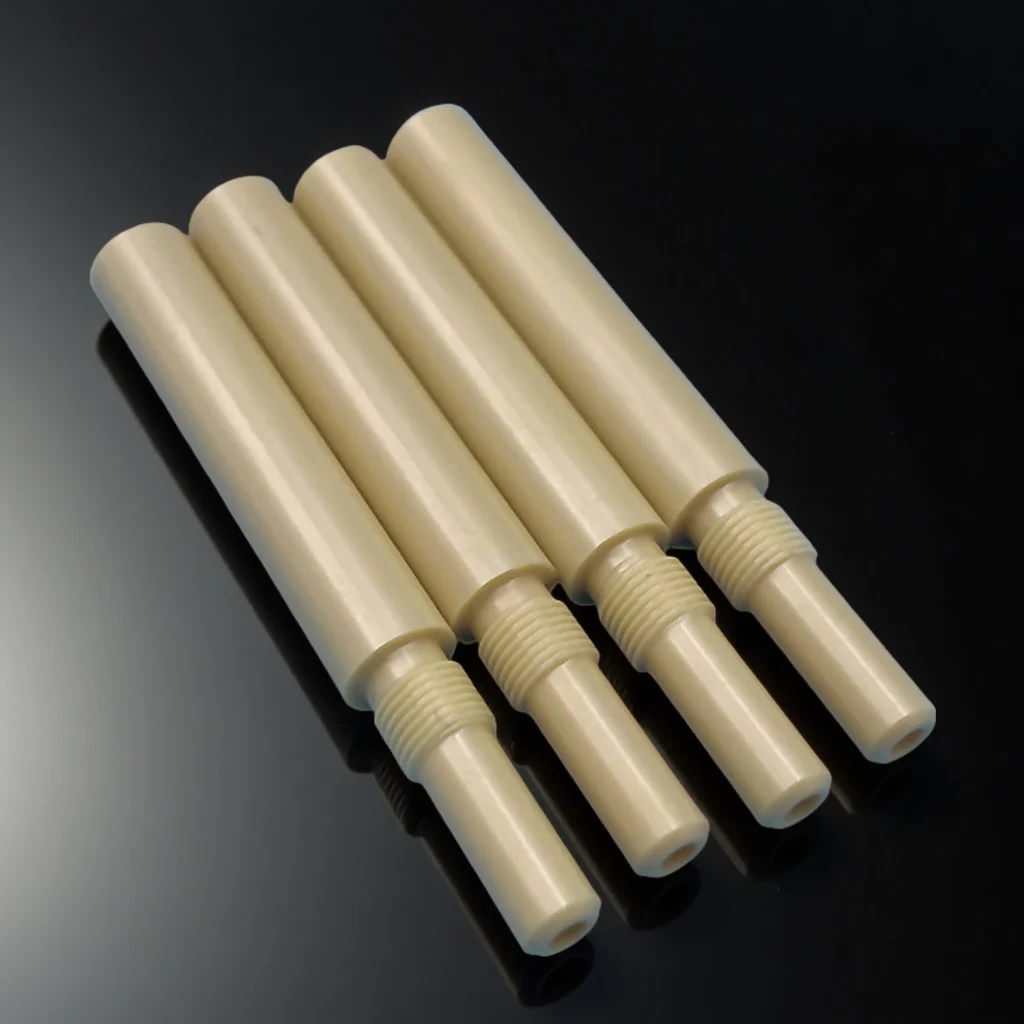

Ceramic Machine Parts are precision ceramic components used to hold alignment and fit in demanding mechanical assemblies. Pins, sleeves, bushings, and custom locators are made to tight tolerances for stable geometry and repeatable positioning.

Semiconductor Ceramic Parts

Semiconductor ceramic parts are high-purity, tight-tolerance components built for clean, stable handling in process equipment. Typical parts include wafer boats, slotted plates, insulating rings, electrostatic chuck ceramics, and polishing plates with controlled surface finish and consistent geometry.

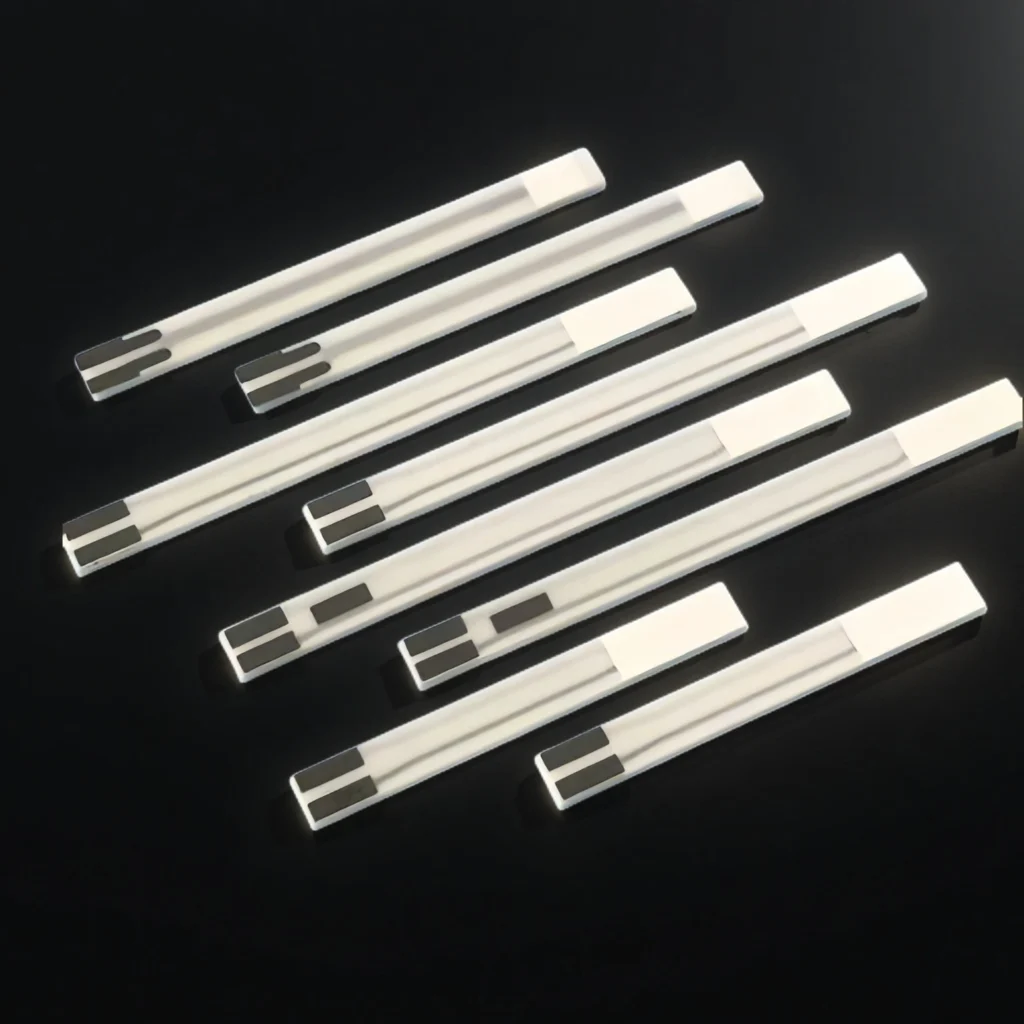

Electronic Ceramic Components

Electronic Ceramic Components are precision technical-ceramic parts used to control insulation, alignment, and thermal stability in electronic assemblies. Typical items include laser cutting heads, sensor chips, V-grooves, ferrules, and relay housings for consistent fit and repeatable performance.

Other Ceramic Components

Other Ceramic Components cover specialized and non-standard ceramic parts made for unique geometries, materials, or surface requirements. This category includes custom labware, optical ceramic parts, grinding and milling components, and application-specific pieces produced to drawing or sample.

Industrial Ceramic Components — Reduce Wear, Leakage, and Drift in Critical Assemblies.

Precision Ceramic Components Applications

Precision ceramic components are commonly used in mechanical equipment, industrial processing systems, semiconductor tools, electronic assemblies, and aerospace hardware. Typical use cases include guiding, sealing, insulating, positioning, and wear interfaces in fit-critical builds.

Mechanical & Automation Equipment

Precision ceramics are widely used in motion systems and automated equipment where repeatable alignment, low wear, and dimensional stability are required.

Typical applications :

💠heat Positioning pins, guide sleeves, spacers

💠Ceramic bushings and wear pads

💠Structural and alignment fixtures for robotic systems

🧩Why need ceramic parts

- Maintain geometry under continuous motion

- Reduce abrasion and particle generation

- Non-magnetic and electrically insulating

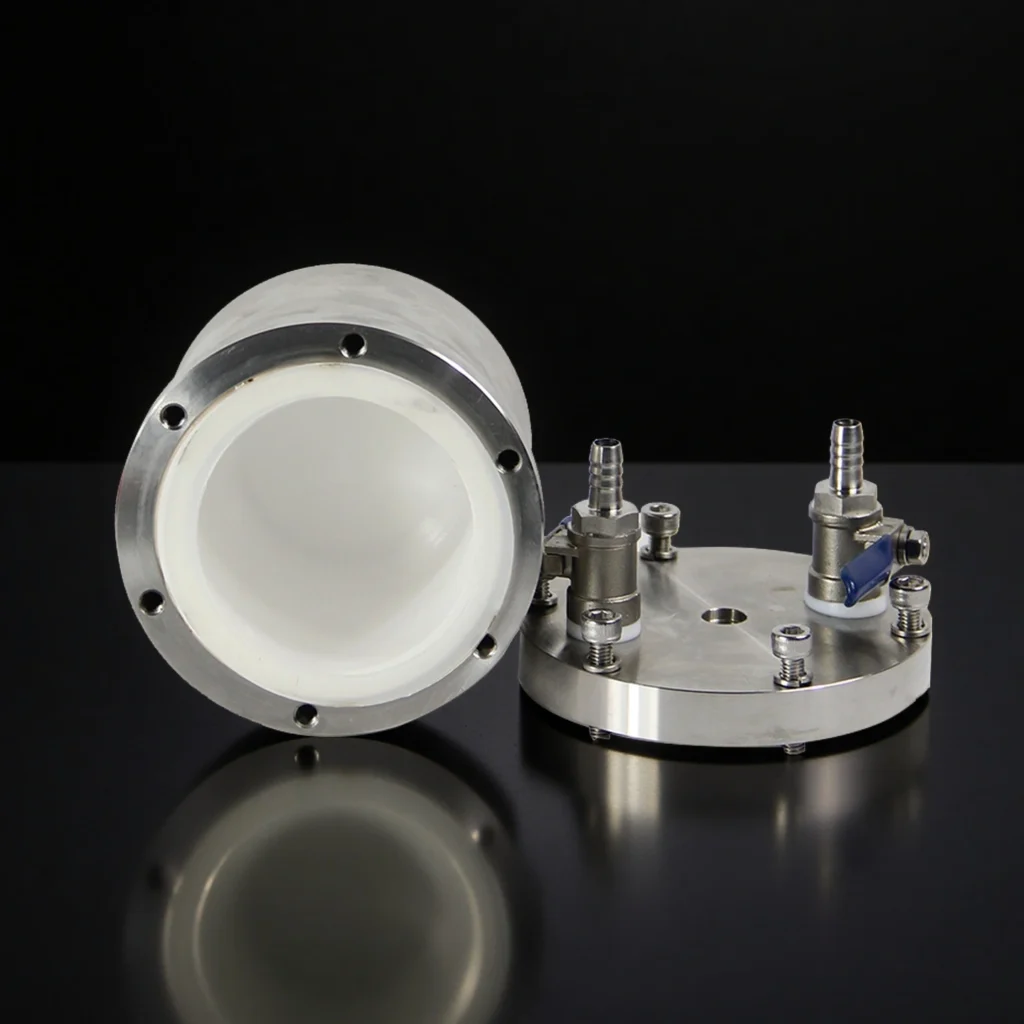

Industrial Processing & Heavy Equipment

In harsh industrial environments, ceramic components extend service life by resisting abrasion, corrosion, and thermal cycling.

Typical applications :

💠Pump and valve components (seats, sleeves, plungers)

💠Kiln fixtures, furnace supports, insulation parts

💠Wear plates, nozzles, and sealing elements

🧩Why need ceramic components:

- Stable performance in corrosive and high-temperature service

- Lower maintenance frequency than metal alternatives

- Improved uptime in continuous-duty systems

Semiconductor Equipment

Precision ceramic components support clean handling, thermal control, and electrical isolation in semiconductor manufacturing equipment.

Typical applications :

💠Wafer boats and carriers

💠Slotted plates and insulating rings

💠Electrostatic chuck ceramics and polishing plates

🧩Why need to ceramic parts:

- High purity and low contamination risk

- Tight tolerances for process repeatability

- Stable behavior under heat and plasma exposure

Electronic & Electrical Systems

Ceramic components are used where electrical insulation, thermal stability, and precise positioning are critical to device reliability.

Typical applications :

💠Ceramic substrates and V-grooves

💠Ferrules, sensor housings, relay and connector components

💠Laser and optical alignment parts

🧩Why need ceramic parts:

- Excellent dielectric strength

- Controlled thermal expansion

- Consistent performance in compact assemblies

Aerospace & High-Reliability Systems

In aerospace and advanced engineering systems, ceramic parts are chosen for strength-to-weight efficiency and resistance to extreme conditions.

Typical applications :

💠Structural and positioning components

💠Insulating and wear-resistant elements

💠Precision fixtures for testing and assembly

🧩Why need ceramic parts

- High temperature capability without creep

- Resistance to oxidation and fatigue

- Dimensional reliability in demanding environments

ADCERAX: A Trusted China Ceramic Parts & Components Supplier

ADCERAX is a ceramic parts manufacturer in china, supplying precision ceramic parts with controlled production and batch inspection for consistent dimensions, surface finish, and fit. Fast engineering support helps confirm drawings, tolerances, material grade (alumina/zirconia), and lead time for reliable assembly and repeatable replacements.

Competitive pricing with strict quality control from raw material sourcing to final delivery

Professional team providing comprehensive technical support and collaborative design

Small batch orders to large-scale production with complex geometries and tight tolerances

24-hour response and 24-hour dispatch for standard items, 3-7 weeks for custom orders.

ADCERAX Ceramic Component Manufacturer

ADCERAX is a factory-direct ceramic parts and ceramic components factory with 20+ years of advanced ceramics experience, delivering precision ceramic parts in alumina and zirconia for harsh-duty service where wear, heat, corrosion, and dimensional drift drive early failure.

Standard ceramic parts are available for fast replacement, and custom ceramic parts built to drawing cover fit-critical features such as tolerances, surface finish, holes/slots, threads, sealing faces, and mating geometry. With batch inspection, traceable records, and export-ready packing, ADCERAX helps buyers keep assemblies stable, reduce scrap and rework, and maintain predictable maintenance cycles.

Ceramic Parts Quality & Certifications

Custom Ceramic Parts & Components

ADCERAX supplies custom ceramic parts and ceramic components in alumina and zirconia for fit-critical industrial assemblies.

Each build is engineered to control wear, heat drift, corrosion attack, and electrical isolation at the interface—so parts seat correctly, run longer, and stay consistent across batches.

Contact ADCERAX to share your drawing/specs and get a fast material + tolerance recommendation with a factory-direct quote.

FAQs About Ceramic Components & Parts

Choose by dominant failure mode:

Alumina (Al₂O₃): best cost/performance for insulation, wear, and chemical stability in many industrial duties; great for general precision ceramic parts.

Zirconia (ZrO₂): higher toughness and impact tolerance; strong for fit-critical components where chipping risk is high.

Silicon Carbide (SiC): excels in abrasive wear and many corrosive/thermal environments; good where stiffness and thermal stability matter.

Silicon Nitride (Si₃N₄): high strength and fatigue resistance; preferred for dynamic mechanical components and high reliability motion parts.

If you share media/temperature/pressure/particle size and mechanical loading, the choice becomes straightforward and defensible.

You can buy wholesale complicated shaped ceramic components from ADCERAX, a ceramic component manufacturer in China. They handle complex 3D parts in alumina, zirconia, silicon carbide, silicon nitride and other technical ceramics.

Send your 2D/3D drawings, material and quantity, and ADCERAX can quote wholesale pricing and lead time for your custom shapes.

Most engineering ceramic parts are made by four main steps: the ceramic powder is blended with binders, formed into a “green” shape (by pressing, injection molding, extrusion, or casting), then debinded and sintered at high temperature so it becomes hard and dense, and finally finished by diamond grinding or lapping to reach the required tolerances and surface finish.

For buyers, the key takeaway is that shape complexity, tolerance level, and order quantity directly affect which process is used, and this is what drives the final price and lead time.

Most alumina ceramic parts we supply are custom-made, so we do not have a fixed public pricelist. Pricing depends on geometry, tolerances, alumina grade, surface finish, and order quantity.

If you send your drawing (2D/3D), material requirement, and expected quantity, ADCERAX can quickly prepare a clear quotation sheet or sample price range for the alumina ceramic parts you need.

Yes. ADCERAX can custom-produce ceramic screw parts to your 2D/3D drawings or samples in alumina, zirconia and other engineering ceramics.

Send us your drawing (with thread standard and tolerances), material requirement, and quantities, and we will confirm manufacturability and provide a clear quote with lead time.

Ceramic parts are first made as a “green body” by shaping ceramic powder with binders, then densified by debinding and high-temperature sintering. The green body can be formed by dry or isostatic pressing (simple blocks, rings, discs), extrusion (tubes, rods, profiles), injection molding (small, complex parts), or casting / 3D printing (special geometries). In practice, the choice of forming method is driven by part geometry, tolerances, and production volume, because these factors control tooling cost, unit price, and achievable precision.

Yes. ADCERAX can machine ceramic parts in the green state and after sintering using diamond tools. We work with alumina, zirconia, silicon nitride, silicon carbide and other technical ceramics, and can grind, drill, slot, lap and polish to tight tolerances.

Send your drawing with key dimensions, tolerances and surface finish, and we will confirm machinability and quote fully finished ceramic parts.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

info@adcerax.com

Telephone: +(86) 0731-74427743

WhatsApp: +(86) 19311583352

Within 24 hours

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.