Electrical Ceramics in Industrial Systems

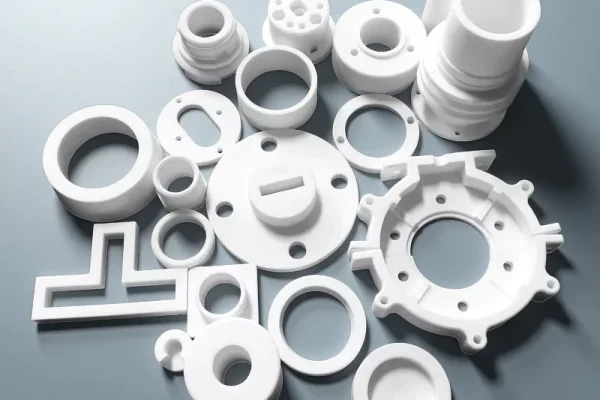

Electrical ceramics refer to a class of industrial ceramics specifically used as electrical ceramic components where insulation stability, heat resistance, and structural reliability are required under real operating conditions.

In industrial systems, electrical ceramic parts replace metals and polymers when voltage stress, temperature exposure, or chemical environments exceed conventional material limits.

As a result, electrical ceramics for industrial applications are widely adopted in power equipment, industrial electronics, and high-voltage assemblies where long-term performance consistency is critical.

Accordingly, electrical ceramics for insulation and high voltage are selected not for appearance or form, but for predictable electrical behavior and controlled material properties over time.

maintains structure under sustained heat

tolerates corrosive industrial atmospheres

resists leakage under high voltage

supports loads without deformation

Material Properties Behind ADCERAX® Electrical Ceramics Performance

Electrical ceramics used in industrial systems are evaluated through measurable thermal, electrical, chemical, and mechanical properties rather than general material descriptions.

Thermal Properties of Electrical Ceramics

| Material | Thermal Conductivity (W/m·K) | Max Service Temperature (°C) | Thermal Expansion (×10⁻⁶/K) | Test Conditions |

|---|---|---|---|---|

| Alumina (96–99%) | 20–30 | 1500–1700 | 7.5–8.5 | Air atmosphere, steady-state |

| ZTA (Zirconia Toughened Alumina) | 18–25 | 1400–1600 | 8.0–9.0 | Air atmosphere, steady-state |

| Zirconia (YSZ) | 2–3 | 1000–1200 | 10.0–11.0 | Air atmosphere, steady-state |

| Aluminum Nitride (AlN) | 140–200 | 900–1000 | 4.5–5.5 | Inert atmosphere |

| Silicon Nitride (Si₃N₄) | 20–35 | 1200–1400 | 3.0–3.5 | Air atmosphere |

| Boron Nitride (h-BN) | 30–60 | 900–1000 | 1.0–2.0 | Inert atmosphere |

| Silicon Carbide (SiC) | 120–180 | 1400–1600 | 4.0–4.5 | Air atmosphere |

| Magnesia (MgO) | 45–60 | 1600–1800 | 12.0–13.5 | Air atmosphere |

| Glass-Ceramic | 1.5–3.0 | 700–900 | 0.0–2.0 | Air atmosphere |

Electrical Properties of Electrical Ceramics

| Material | Volume Resistivity (Ω·cm) | Dielectric Strength (kV/mm) | Dielectric Constant (1 MHz) | Test Conditions |

|---|---|---|---|---|

| Alumina (96–99%) | ≥10¹⁴ | 12–20 | 9.0–9.8 | Room temperature, dry |

| ZTA | ≥10¹³ | 10–18 | 9.5–10.5 | Room temperature, dry |

| Zirconia | ≥10¹¹ | 8–12 | 20–30 | Room temperature, dry |

| Aluminum Nitride | ≥10¹³ | 15–18 | 8.5–9.0 | Room temperature, dry |

| Silicon Nitride | ≥10¹² | 12–15 | 7.5–8.5 | Room temperature, dry |

| Boron Nitride | ≥10¹⁵ | 25–35 | 3.5–4.0 | Room temperature, dry |

| Silicon Carbide | 10²–10⁵ | 2–5 | 9.5–10.0 | Room temperature |

| Magnesia | ≥10¹³ | 8–12 | 9.5–10.5 | Room temperature |

| Glass-Ceramic | ≥10¹⁴ | 15–25 | 4.5–6.5 | Room temperature |

Chemical Stability of Electrical Ceramics

| Material | Acid Resistance | Alkali Resistance | Oxidation Stability | Test Conditions |

|---|---|---|---|---|

| Alumina | Stable to HCl, H₂SO₄ | Limited NaOH resistance | Stable ≤1000 °C | 24 h immersion |

| ZTA | Similar to alumina | Slightly reduced vs Al₂O₃ | Stable ≤1000 °C | 24 h immersion |

| Zirconia | Stable to most acids | Stable to alkalis | Stable ≤800 °C | 24 h immersion |

| Aluminum Nitride | Reacts with water | Poor alkali resistance | Stable ≤700 °C | Controlled humidity |

| Silicon Nitride | Stable to acids | Moderate alkali resistance | Stable ≤900 °C | 24 h immersion |

| Boron Nitride | Chemically inert | Chemically inert | Stable ≤900 °C | 24 h immersion |

| Silicon Carbide | Highly inert | Highly inert | Stable ≤1000 °C | 24 h immersion |

| Magnesia | Poor acid resistance | Stable to alkalis | Stable ≤1200 °C | 24 h immersion |

| Glass-Ceramic | Stable to weak acids | Limited alkali resistance | Stable ≤700 °C | 24 h immersion |

Mechanical Properties of Electrical Ceramics

| Material | Flexural Strength (MPa) | Hardness (HV) | Fracture Toughness (MPa·m¹ᐟ²) | Test Conditions |

|---|---|---|---|---|

| Alumina (96–99%) | 300–400 | 1200–1600 | 3.0–4.0 | 3-point bend |

| ZTA | 450–650 | 1100–1400 | 5.0–7.0 | 3-point bend |

| Zirconia | 800–1200 | 1100–1300 | 6.0–10.0 | 3-point bend |

| Aluminum Nitride | 300–350 | 1100–1300 | 2.5–3.5 | 3-point bend |

| Silicon Nitride | 700–1000 | 1400–1600 | 5.0–7.0 | 3-point bend |

| Boron Nitride | 50–100 | 200–400 | 1.0–1.5 | 3-point bend |

| Silicon Carbide | 350–450 | 2200–2600 | 3.0–4.5 | 3-point bend |

| Magnesia | 150–250 | 600–800 | 1.5–2.5 | 3-point bend |

| Glass-Ceramic | 100–200 | 500–700 | 1.5–2.0 | 3-point bend |

ADCERAX® Electrical Ceramics Application Domains

Electrical ceramics are applied across industrial electrical systems based on functional roles such as insulation continuity, thermal control, mechanical stability, and packaging integration.

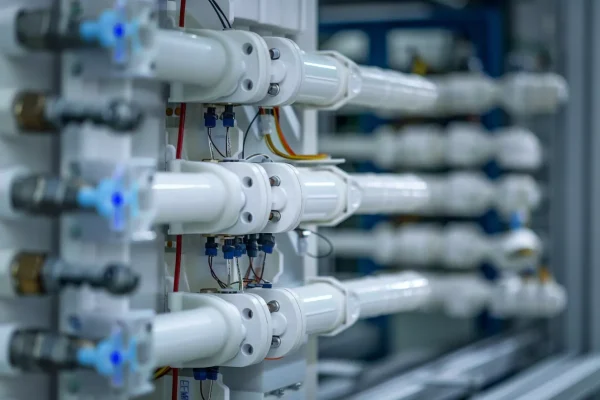

High Voltage Electrical Insulation Assemblies

Electrical ceramics are essential in high-voltage systems where insulation failure leads to electrical leakage, thermal degradation, and safety risks.

- Electrical ceramics for high voltage maintain dielectric stability under sustained electric fields and temperature gradients.

- Electrical ceramic components prevent partial discharge and surface tracking in compact insulation assemblies.

- Electrical ceramics for industrial applications support long-term insulation reliability beyond polymer limits.

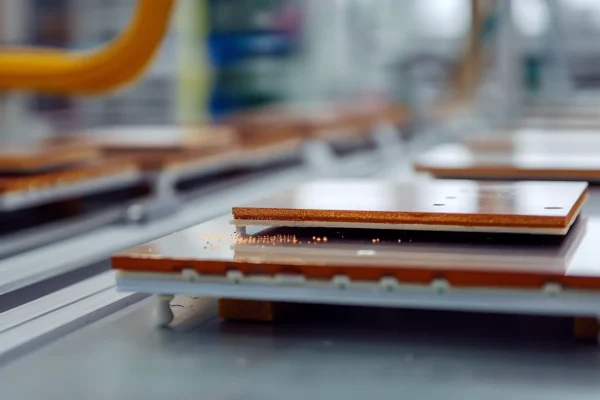

Power Electronics Substrate Integration Systems

Power electronic systems rely on ceramic substrates to balance insulation, heat dissipation, and dimensional stability within compact assemblies.

- Electrical ceramics for power equipment isolate conductive layers while enabling controlled thermal transfer.

- Electrical ceramics for industrial electronics support stable circuit performance under repeated thermal cycling.

- Electrical ceramic parts reduce failure risks caused by CTE mismatch and localized overheating.

Thermal Control and Heating Systems

Electrical ceramics enable precise thermal generation and dissipation while maintaining electrical insulation in heated environments.

- Electrical ceramics ensure uniform heat distribution without electrical leakage in heating assemblies.

- Electrical ceramic components remain dimensionally stable under continuous thermal cycling.

- Electrical ceramics for industrial applications support controlled heating where metal elements degrade.

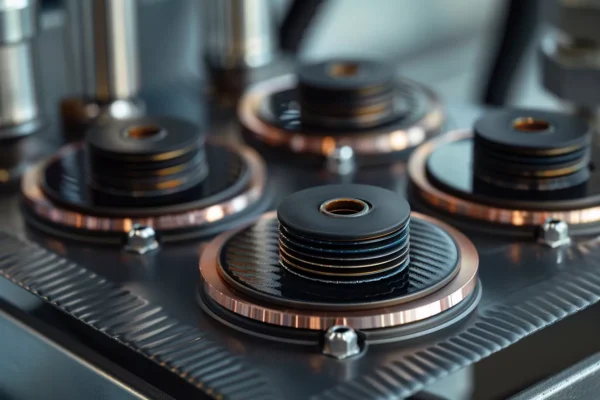

Mechanical Load Bearing Electrical Structures

Certain electrical systems require ceramics to carry mechanical loads while maintaining insulation and geometric accuracy.

- Electrical ceramic parts resist deformation under mechanical stress and electrical exposure.

- Electrical ceramics maintain dimensional accuracy where vibration and wear coexist.

- Electrical ceramics for industrial applications reduce maintenance caused by material fatigue.

Electrical Packaging and Interface Integration

Packaging systems depend on electrical ceramics to integrate insulation, conductive interfaces, and structural alignment.

- Electrical ceramics provide hermetic insulation in compact electrical housings.

- Electrical ceramic components support metal-ceramic interfaces without signal degradation.

- Electrical ceramics for industrial electronics ensure long-term package integrity under thermal stress.

Electrical Ceramics Integrated at System Level

Electrical ceramics perform best when material properties align with system-level electrical and thermal behavior.

ADCERAX® works from application context backward to ensure ceramic components fit the complete electrical assembly.

ADCERAX® Electrical Ceramics Portfolio Overview

ADCERAX® organizes its electrical ceramics portfolio by material systems to help engineers and procurement teams quickly align performance requirements with suitable electrical ceramic components.

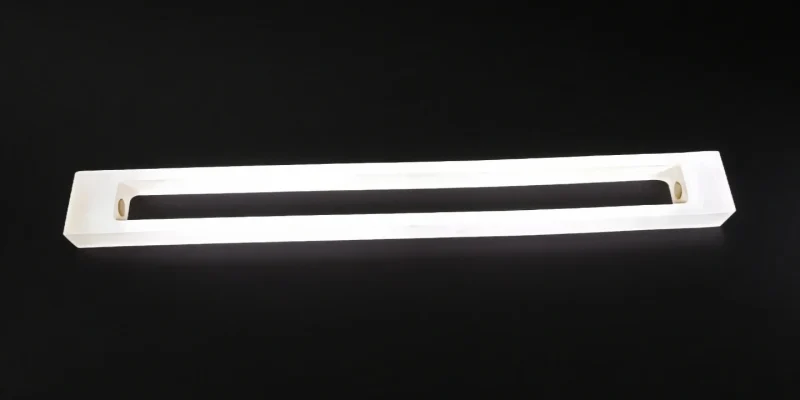

Alumina Ceramics

Alumina-based electrical ceramic parts form the core solution for insulation and structural stability in industrial electrical systems.

- Broad insulation voltage coverage

- Stable thermal electrical balance

- High repeatability supply

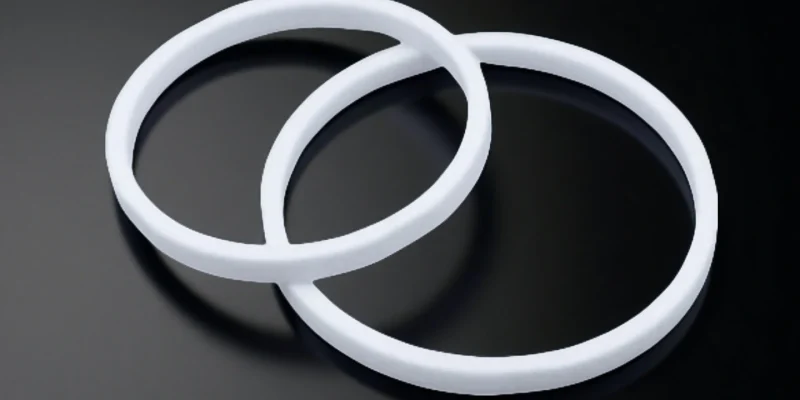

Zirconia Ceramics

Zirconia electrical ceramic components are applied where high mechanical strength and precision geometry are required alongside insulation.

- High strength compact structures

- Precision finishing capability

- Wear resistant ceramic parts

Aluminum Nitride Ceramics

Aluminum nitride electrical ceramics address heat dissipation challenges in power electronics and industrial electronics.

- Improved crack resistance performance

- Higher mechanical safety margin

- Suitable vibration exposed assemblies

Silicon Nitride Ceramics

Silicon nitride electrical ceramic parts combine structural reliability with thermal endurance in electrically stressed environments.

- High strength insulation structures

- Thermal cycling tolerance

- Long service reliability

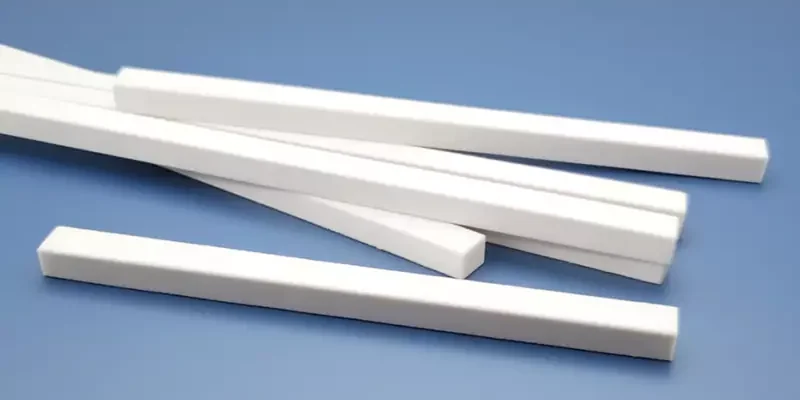

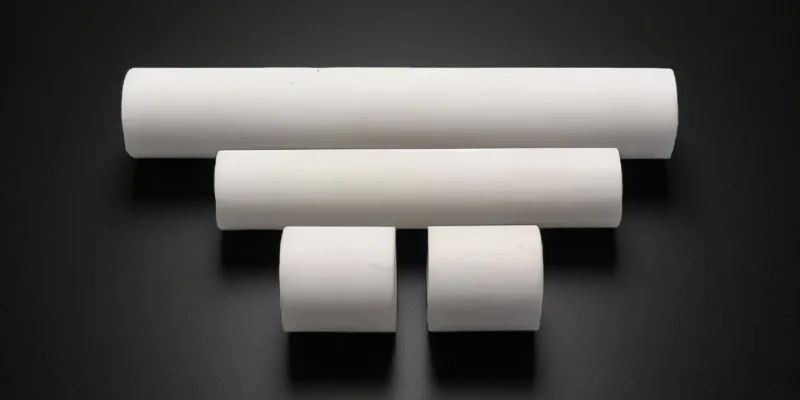

Boron Nitride Ceramics

Boron nitride electrical ceramics provide insulation performance under high temperature with non-wetting characteristics.

- High temperature electrical insulation

- Chemical inert processing behavior

- Easy machining flexibility

Silicon Carbide Ceramics

Silicon carbide ceramic parts are selectively used for electrically adjacent high-temperature or wear-intensive applications.

- Extreme temperature stability

- High wear resistance

- Long operational lifespan

Magnesia Ceramics

Magnesia electrical ceramics are applied where electrical insulation must remain stable at elevated temperatures.

- High temperature dielectric stability

- Simple geometry components

- Cost controlled insulation parts

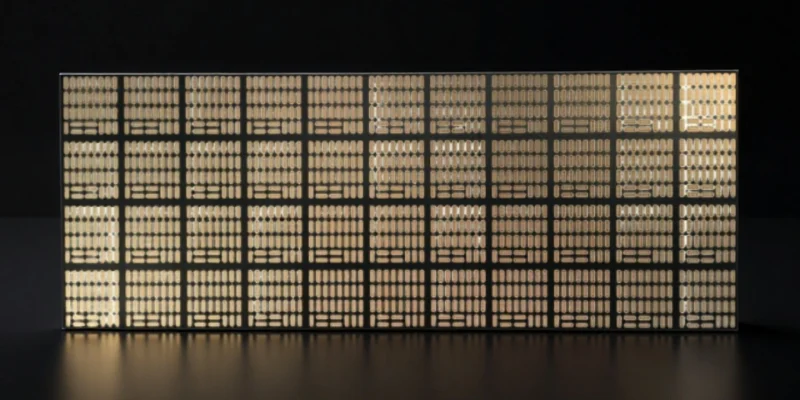

Metallized Ceramics

Metallized electrical ceramic components integrate conductive interfaces for electrical connection and packaging.

- Reliable metal ceramic bonding

- Electrical signal compatibility

- Packaging assembly integration

Glass Ceramics

Glass ceramic electrical parts support electrical insulation with low thermal expansion in precision assemblies.

- Controlled thermal expansion

- Dimensional stability maintained

- Specialized electrical assemblies

Integrated Processing Services for Electrical Ceramics

ADCERAX® provides consolidated manufacturing services that support electrical ceramic components from early-stage validation through stable production.

Each process step is aligned with the performance needs of electrical ceramics for industrial applications, ensuring consistency across materials, geometry, and final use conditions.

Engineering drawing review and feasibility assessment

Material selection and application alignment

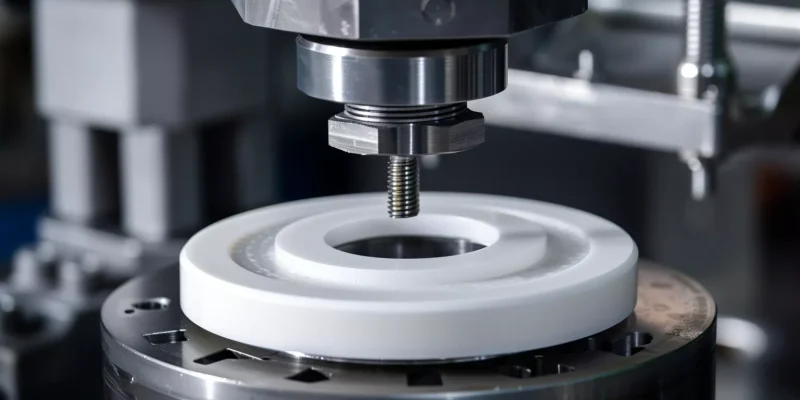

Precision forming and controlled sintering

CNC machining and tolerance finishing

Metallization and functional surface treatment

Dimensional inspection and electrical testing

ADCERAX® Process Capabilities Behind Electrical Ceramics Manufacturing

Precision Forming and Sintering

Stable electrical performance begins with forming and sintering that determines density, insulation integrity, and dimensional reliability.

Uniform green density above 98% theoretical

Temperature stability within ±3 °C range

Grain size controlled at 3–5 µm

CNC Machining and Tolerance Finishing

Post-sintering machining that balances dimensional accuracy with surface integrity under electrical stress.

Dimensional tolerance maintained within ±0.02 mm

Ra surface roughness reduced below 0.8 µm

Chamfer integrity prevents voltage concentration

Functional Surface Processing

For electrical ceramics used in packaging and interfaces, surface treatments define bonding reliability and long-term electrical stability.

Bond strength exceeding 120 MPa shear

Coating thickness controlled at 5–10 µm

Thermal cycling endurance beyond 500 cycles

Electrical Ceramics Customization for Engineering Projects

ADCERAX® supports custom electrical ceramics by translating drawings, samples, and operating conditions into manufacturable ceramic solutions.

Customization covers material systems, geometries, tolerances, and surface treatments aligned with real electrical and thermal requirements.

Start a technical discussion with ADCERAX® to confirm feasibility, lead time, and production scalability for your application.

ADCERAX® Electrical Ceramics Technical Questions for Engineering Applications

Electrical ceramics maintain extremely high volume resistivity, typically above 10¹³–10¹⁵ Ω·cm, even at elevated temperatures.

This prevents leakage current growth that often triggers partial discharge in polymer or composite insulators.

As a result, electrical ceramics provide stable insulation margins in high-voltage electrical assemblies over long service cycles.

Unlike organic materials, electrical ceramics do not age through molecular breakdown or plastic deformation.

Their dielectric strength remains stable under continuous electrical stress and thermal cycling.

This stability directly reduces insulation drift in power equipment and industrial electronics.

Electrical ceramics simultaneously offer high dielectric strength and controlled thermal conductivity.

This allows heat generated by electrical losses to dissipate without compromising insulation integrity.

Such coupling performance is critical in compact power electronics and high-density electrical systems.

High-purity electrical ceramics reduce ionic impurities that act as charge migration paths.

Lower impurity levels directly improve breakdown voltage and reduce dielectric loss.

This advantage becomes especially important in high-frequency or high-voltage electrical ceramics applications.

Electrical ceramics maintain dimensional and electrical stability under vibration and thermal cycling.

This prevents micro-crack propagation that can alter electrical clearances over time.

The result is predictable electrical performance in industrial electronics operating continuously.

The dense, non-porous microstructure of electrical ceramics limits surface contamination absorption.

This suppresses conductive film formation that often leads to surface tracking.

Consequently, electrical ceramics perform reliably in humid or polluted electrical environments.

High dielectric strength allows electrical ceramics to maintain insulation at reduced wall thicknesses.

This enables smaller clearances without increasing failure risk.

Designers use this advantage to achieve compact layouts in power equipment and electrical modules.

Electrical ceramics exhibit low dielectric loss across a wide frequency range.

This minimizes signal attenuation and heat generation during high-frequency operation.

Such characteristics are essential in electrical ceramics for industrial electronics and control systems.

The low and stable thermal expansion of electrical ceramics reduces internal stress buildup.

This prevents dimensional drift during repeated heating and cooling cycles.

Stable geometry preserves electrical spacing and alignment in precision electrical assemblies.

Electrical ceramics remain chemically inert to oils, solvents, and industrial atmospheres.

Polymers often degrade, swell, or lose dielectric strength under similar exposure.

This chemical resistance extends service life in demanding electrical installations.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.