Engineering Ceramic Parts Applied in Automotive Environments

Automotive Industrial Ceramic parts describe engineered ceramic components used where heat, electrical load, wear, and chemical exposure converge within vehicle systems.

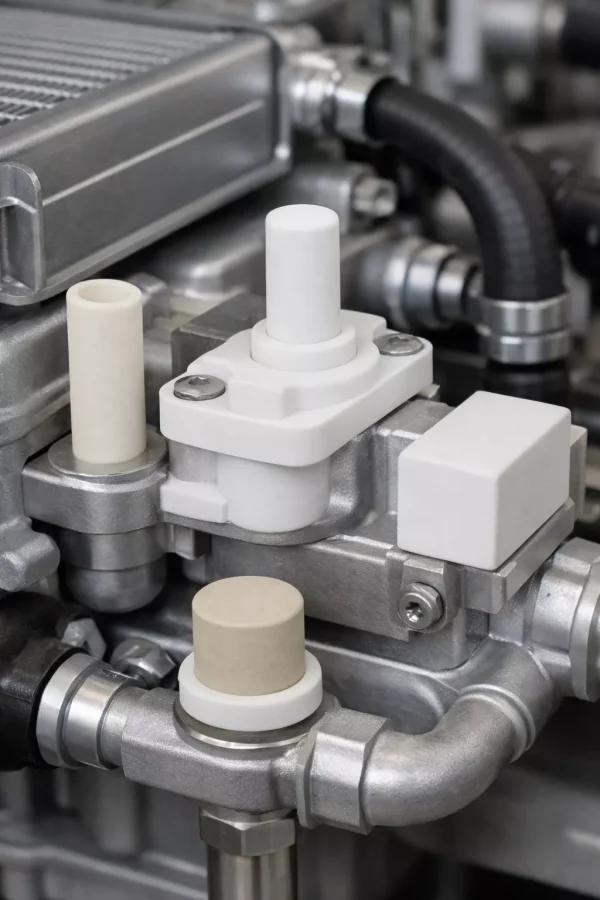

Within automotive platforms, ceramic components applied in automotive environments appear as sensor housings, insulation structures, wear interfaces, and functional flow elements rather than cosmetic or non-critical features.

Compared with metals and polymers, ceramic parts applied in automotive equipment maintain dimensional and functional stability as temperature increases, electrical conditions fluctuate, and mechanical cycles repeat over extended service life.

Accordingly, Automotive Engineering Ceramic components are specified in powertrain assemblies, exhaust treatment systems, new energy platforms, and automated manufacturing equipment where performance margins are tightly controlled and failure tolerance remains minimal.

sustained strength under continuous high temperatures

limited degradation in corrosive exhaust environments

reliable dielectric behavior under elevated voltage

reduced wear under repetitive contact and load

ADCERAX® Automotive Technical Ceramic Material Properties Under Operating Stress

Industrial Ceramic are evaluated through measurable physical and chemical parameters that determine how ceramic components applied in automotive environments maintain reliability under heat, electrical stress, wear, and corrosive exposure.

Thermal Properties

| Material | Max Continuous Temperature (°C) | Thermal Conductivity (W/m·K) | Thermal Expansion (×10⁻⁶/K) | Thermal Shock ΔT (°C) | Test Conditions |

|---|---|---|---|---|---|

| Alumina Ceramic (96%) | 1600 | 24 | 7.8 | 200 | Air, steady-state |

| ZTA Ceramic | 1500 | 18 | 7.5 | 220 | Air, cyclic heating |

| Zirconia Ceramic (Y-TZP) | 1000 | 2.5 | 10.5 | 300 | Air, rapid quench |

| Silicon Carbide Ceramic | 1650 | 120 | 4.2 | 500 | Oxidizing atmosphere |

| Nitride Bonded Silicon Carbide | 1400 | 30 | 4.5 | 450 | Nitrogen atmosphere |

| Silicon Nitride Ceramic | 1400 | 30 | 3.2 | 600 | Air, thermal cycling |

| Boron Nitride Ceramic | 900 | 60 | 1.0 | 700 | Inert atmosphere |

| Aluminum Nitride Ceramic | 900 | 170 | 4.5 | 300 | Air, steady-state |

| Glass Ceramic | 800 | 1.5 | 1.2 | 250 | Air, slow heating |

| Aluminum Titanate Ceramic | 1400 | 2.0 | 1.0 | 1000 | Air, thermal shock |

Electrical Properties

| Material | Volume Resistivity (Ω·cm) | Dielectric Strength (kV/mm) | Dielectric Constant (1 MHz) | Loss Tangent | Test Conditions |

|---|---|---|---|---|---|

| Alumina Ceramic | 10¹⁴ | 15 | 9.5 | 0.0002 | 25 °C, dry air |

| ZTA Ceramic | 10¹³ | 14 | 9.8 | 0.0003 | 25 °C |

| Zirconia Ceramic | 10⁹ | 8 | 25 | 0.002 | 25 °C |

| Silicon Carbide Ceramic | 10⁵ | 3 | 10 | 0.01 | 25 °C |

| Nitride Bonded Silicon Carbide | 10⁶ | 4 | 9 | 0.008 | 25 °C |

| Silicon Nitride Ceramic | 10¹² | 12 | 8.5 | 0.0005 | 25 °C |

| Boron Nitride Ceramic | 10¹⁵ | 20 | 4.0 | 0.0001 | 25 °C |

| Aluminum Nitride Ceramic | 10¹³ | 15 | 8.8 | 0.0003 | 25 °C |

| Glass Ceramic | 10¹⁴ | 18 | 6.0 | 0.0002 | 25 °C |

| Aluminum Titanate Ceramic | 10¹¹ | 10 | 7.0 | 0.001 | 25 °C |

Chemical Stability

| Material | Acid Resistance (pH 1) | Alkali Resistance (pH 14) | Oxidation Stability (°C) | Molten Metal Compatibility | Test Conditions |

|---|---|---|---|---|---|

| Alumina Ceramic | ≤0.2 mg/cm² loss | ≤0.5 mg/cm² loss | 1600 | Limited | 24 h immersion |

| ZTA Ceramic | ≤0.2 mg/cm² loss | ≤0.4 mg/cm² loss | 1500 | Limited | 24 h immersion |

| Zirconia Ceramic | ≤0.3 mg/cm² loss | ≤0.6 mg/cm² loss | 1000 | Poor | 24 h immersion |

| Silicon Carbide Ceramic | ≤0.05 mg/cm² loss | ≤0.1 mg/cm² loss | 1650 | Good | 24 h immersion |

| Nitride Bonded Silicon Carbide | ≤0.1 mg/cm² loss | ≤0.2 mg/cm² loss | 1400 | Excellent | 24 h immersion |

| Silicon Nitride Ceramic | ≤0.1 mg/cm² loss | ≤0.3 mg/cm² loss | 1400 | Excellent | 24 h immersion |

| Boron Nitride Ceramic | ≤0.05 mg/cm² loss | ≤0.05 mg/cm² loss | 900 | Excellent | Inert environment |

| Aluminum Nitride Ceramic | ≤0.2 mg/cm² loss | ≤0.8 mg/cm² loss | 900 | Limited | Controlled humidity |

| Glass Ceramic | ≤0.1 mg/cm² loss | ≤0.3 mg/cm² loss | 800 | Poor | 24 h immersion |

| Aluminum Titanate Ceramic | ≤0.2 mg/cm² loss | ≤0.4 mg/cm² loss | 1400 | Excellent | 24 h immersion |

Mechanical Properties

| Material | Flexural Strength (MPa) | Fracture Toughness (MPa·m¹ᐟ²) | Hardness (HV) | Elastic Modulus (GPa) | Test Conditions |

|---|---|---|---|---|---|

| Alumina Ceramic | 300 | 3.5 | 1500 | 380 | Room temperature |

| ZTA Ceramic | 450 | 5.0 | 1400 | 350 | Room temperature |

| Zirconia Ceramic | 1000 | 9.0 | 1300 | 210 | Room temperature |

| Silicon Carbide Ceramic | 400 | 4.0 | 2500 | 410 | Room temperature |

| Nitride Bonded Silicon Carbide | 250 | 3.5 | 2000 | 300 | Room temperature |

| Silicon Nitride Ceramic | 900 | 7.0 | 1600 | 320 | Room temperature |

| Boron Nitride Ceramic | 80 | 2.0 | 200 | 40 | Room temperature |

| Aluminum Nitride Ceramic | 350 | 3.0 | 1100 | 310 | Room temperature |

| Glass Ceramic | 120 | 2.5 | 600 | 90 | Room temperature |

| Aluminum Titanate Ceramic | 40 | 1.8 | 500 | 20 | Room temperature |

Ceramic Components Applied in Automotive Environments and Systems

Engineering ceramic parts are selected by application scenario because ceramic components applied in automotive environments must withstand distinct combinations of heat, electrical stress, wear, chemical exposure, and service-life demands across vehicle systems.

Sensor And Electrical Systems

Within sensor and electrical architectures, automotive industrial ceramic parts are relied upon to maintain electrical insulation integrity and signal consistency when exposed to prolonged thermal load and sustained voltage stress over extended service cycles.

- Alumina Automotive Ceramic maintains electrical insulation integrity when heat and voltage act simultaneously within sensor assemblies.

- Zirconia Automotive Ceramic enables stable electrochemical behavior in oxygen sensing environments exposed to exhaust gas fluctuations.

- Automotive Engineering Ceramic components limit dimensional drift that could otherwise compromise sensor calibration accuracy.

Stable insulation support for sensors under continuous thermal cycling

Electrical isolation structure maintaining geometry under heat exposure

Electrochemical sensing stability under exhaust gas conditions

Precision Positioning And Automation

Across automated production and positioning systems, automotive engineering ceramic components play a critical role by sustaining dimensional accuracy, controlled wear behavior, and repeatable motion under continuous mechanical cycling that directly influences process yield.

- Zirconia Automotive Ceramic provides high fracture toughness to withstand repeated mechanical contact in positioning interfaces.

- Wear Resistant Automotive Ceramic minimizes tolerance drift during high-cycle automated motion and fixture engagement.

- Automotive Structural Ceramic maintains long-term dimensional stability within precision fixture and alignment systems.

High precision alignment support in automated assembly equipment

Repeatable location accuracy under high cycle mechanical loading

Structural rotation stability for precision mechanical assemblies

Wear resistant support for rotating automotive automation systems

Angular positioning accuracy maintained during repeated indexing

Insulating locating element for automated tooling fixtures

Stable wear surface for guided motion components

Dimensional consistency for pad printing equipment operation

Fluid Control And Material Flow

In fluid transfer and molten material handling environments, ceramic parts applied in automotive equipment are specified to resist erosion, heat accumulation, and chemically aggressive media that would otherwise cause rapid degradation of conventional metallic components.

- Silicon Carbide Automotive Ceramic resists erosive wear under continuous high-temperature fluid flow conditions.

- Aluminum Nitride Automotive Ceramic enables controlled heat dissipation while maintaining electrical insulation in fluid interfaces.

- Automotive Engineering Ceramic components limit material degradation when exposed to aggressive chemical media.

Controlled fluid delivery under thermal and chemical exposure

Precision flow stability in abrasive fluid environments

Long life performance under high velocity hot flow

Heat dissipation support combined with electrical insulation

Wear resistant flow guidance under continuous operation

Exhaust And High Temperature Zones

Exhaust systems rely on engineering ceramic components because ceramic parts applied in automotive equipment must tolerate sustained thermal load, rapid temperature transitions, and chemically aggressive gases that exceed the limits of metallic solutions.

- Silicon Carbide Automotive Ceramic maintains mechanical strength under prolonged high exhaust temperatures.

- Thermal Shock Automotive Ceramic limits crack initiation during rapid heating and cooling cycles.

- Automotive Technical Ceramic components reduce corrosion caused by sulfur-containing exhaust streams.

Exhaust gas filtration under continuous high temperature operation

Load bearing stability within high temperature rotating systems

Molten Metal Handling And Casting

In aluminum casting systems, industrial ceramic parts are indispensable because ceramic components applied in automotive environments must endure direct molten metal contact, repeated thermal cycling, and oxidation conditions that rapidly degrade conventional materials.

- Nitride Bonded Silicon Carbide Ceramic provides stable compatibility with molten aluminum during continuous transfer.

- Silicon Nitride Automotive Ceramic retains mechanical strength across repeated heating and cooling cycles.

- Automotive Engineering Ceramic materials reduce thermal stress accumulation under extreme temperature gradients.

Stable molten aluminum transfer during casting cycles

Strength retention under repeated molten metal exposure

Exceptional thermal shock resistance during metal transfer

Release And High Temperature Processing

Specific automotive manufacturing stages depend on them because ceramic parts applied in automotive equipment must prevent material adhesion, ensure clean release, and remain dimensionally stable under sustained high-temperature exposure.

- Boron Nitride Automotive Ceramic creates non-wetting interfaces that enable reliable release from molten materials.

- Glass Ceramic Automotive Ceramic limits thermal expansion to preserve process dimensional control.

- Automotive Technical Ceramic components stabilize processing conditions during repeated high-temperature cycles.

Non wetting transfer channel for high temperature processes

Release support for high temperature forming operations

Dimensional stability under controlled thermal conditions

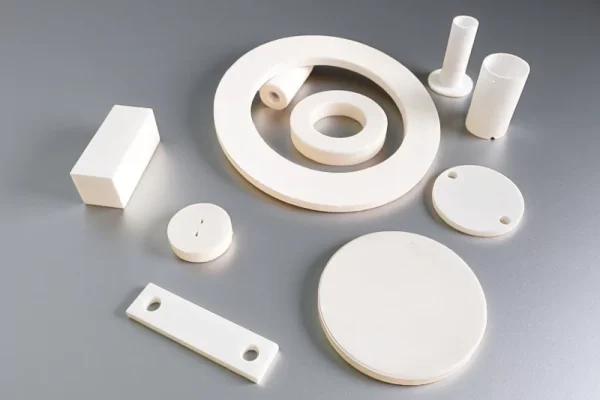

Custom Ceramic Solutions Matched To Automotive Application Stress Profiles

Custom Automotive Ceramic components are frequently required when standard parts cannot satisfy temperature, wear, or insulation constraints.

ADCERAX operates as an Automotive Ceramic Factory supporting drawing-based customization and controlled production for automotive applications.

ADCERAX® Automotive Industrial Ceramic Parts Classified by Material Systems

Automotive Industrial Ceramic parts are commonly grouped by material system to reflect how ceramic components applied in automotive environments respond to heat, wear, electrical load, and chemical exposure across vehicle applications.

Alumina Ceramic

Alumina Automotive Ceramic is widely recognized for its stable insulation behavior and predictable dielectric performance in automotive systems.

- Electrical insulation reliability

- Stable dielectric performance

- Cost efficient scalability

ZTA Ceramic

ZTA Automotive Ceramic combines alumina stability with zirconia reinforcement to significantly improve wear-related durability.

- Enhanced wear resistance

- Improved fracture resistance

- Longer component service life

Zirconia Ceramic

Zirconia Automotive Ceramic is characterized by high fracture toughness and dimensional precision under mechanical stress.

- High fracture toughness

- Precision dimensional stability

- Reliable sensing performance

SiC Ceramic

Silicon Carbide Automotive Ceramic is distinguished by its ability to operate under extreme temperature and chemically aggressive environments.

- Very high temperature capability

- Excellent chemical corrosion resistance

- High thermal conductivity

Si₃N₄ Ceramic

Silicon Nitride Automotive Ceramic exhibits high mechanical strength retention combined with low thermal expansion.

- High mechanical strength

- Superior thermal shock resistance

- Low density structural stability

Boron Nitride Ceramic

Boron Nitride Automotive Ceramic is known for non-wetting behavior and inherent lubricity at elevated temperatures.

- Non wetting surface behavior

- Easy material release

- Stable high temperature lubrication

AlN Ceramic

Aluminum Nitride Automotive Ceramic uniquely balances high thermal conductivity with electrical insulation.

- Very high thermal conductivity

- Electrical insulation capability

- Efficient heat dissipation

Glass Ceramic

Glass Ceramic Automotive Ceramic is defined by low thermal expansion and stable performance under temperature fluctuation.

- Very low thermal expansion

- Stable thermal insulation behavior

- Good dimensional stability

Al₂TiO₅ Ceramic

Aluminum Titanate Automotive Ceramic is specifically known for exceptional resistance to rapid thermal gradients.

- Exceptional thermal shock resistance

- Extremely low thermal expansion

- Stable performance during casting

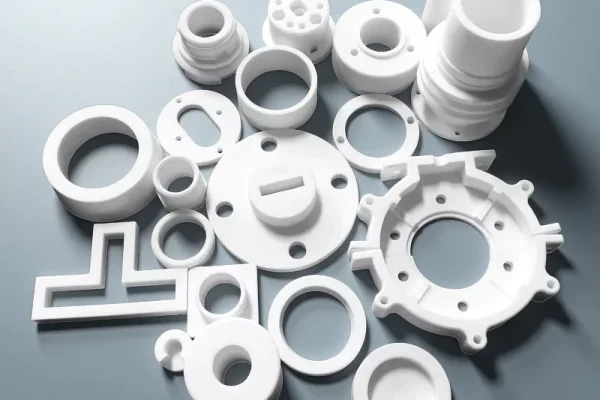

Automotive Industrial Ceramic Parts Manufacturing in Integrated Services

ADCERAX® provides an integrated manufacturing service for Automotive Engineering Ceramic components that addresses common customer pain points such as long validation cycles, inconsistent tolerances, and limited material-process coordination across suppliers.

The service consolidates material selection, forming, sintering, and precision finishing within a single Automotive Ceramic Factory.

From early drawing review to repeatable production readiness, Automotive Industrial Ceramic processing at ADCERAX® is structured to reduce redesign risk and shorten decision time for engineering teams.

Alumina, zirconia, carbide, nitride systems matched to operating stress

Isostatic pressing and extrusion for complex automotive geometries

Controlled firing up to 2100 °C for stable microstructure

Diamond grinding achieving ±0.01–0.03 mm critical tolerances

Functional finishes Ra 0.4–1.6 µm for wear or insulation

ADCERAX® Automotive Structural Ceramic Processing for Dimensional Control

High-Precision

Ceramic Forming

Advanced forming processes determine geometry integrity and internal density before any thermal treatment begins.

Uniform green density above 98% for complex geometries

Stable thin-wall sections down to 1.5–2.0 mm

Green body deviation limited within ±0.5%

Controlled High-Temperature Sintering

Sintering defines microstructure stability and mechanical reliability under automotive operating stress.

Peak firing capability up to 2100 °C

Oxidation or nitrogen environments matched to material systems

Grain growth controlled within ±10% target range

Precision

Ceramic Machining

Final machining translates sintered ceramic strength into functional Automotive Engineering Ceramic components.

Tolerances maintained at ±0.01–0.03 mm

Functional roughness Ra 0.4–1.6 µm achieved

Grooves, bores, and steps with consistent edge quality

Automotive Technical Ceramic Customization for Application Requirements

Custom Automotive Engineering Ceramic components are often required when standard parts cannot maintain dimensional stability, insulation reliability, or wear life under real vehicle operating conditions.

As an automotive industrial ceramic parts manufacturer, ADCERAX® supports drawing-based and sample-based customization by aligning material selection, geometry control, and processing limits to the intended application environment.

ADCERAX® Technical FAQs about Automotive Engineering Ceramic Parts

Ceramic components applied in automotive environments retain mechanical strength and dimensional stability at temperatures where steels and alloys soften or oxidize. This stability prevents deformation in exhaust, sensor, and thermal management systems. Sustained thermal reliability directly reduces premature failure and replacement frequency. ADCERAX® selects material systems specifically matched to long-term thermal exposure.

Automotive Industrial Ceramic parts exhibit high dielectric strength and low electrical leakage under combined heat and voltage stress. This behavior protects sensors, power electronics, and insulation structures from signal drift and short circuits. Insulation performance remains stable over extended operating cycles. ADCERAX® controls material purity and microstructure to ensure consistent electrical behavior.

Automotive Engineering Ceramic components provide low thermal expansion and high stiffness compared with metallic alternatives. These properties minimize dimensional drift during temperature changes and repeated mechanical cycles. Alignment accuracy is preserved in automation and assembly systems. ADCERAX® supports tight-tolerance machining to match fixture and tooling requirements.

ceramic parts applied in automotive equipment demonstrate high hardness and abrasion resistance under sliding or rotating contact. Surface degradation is significantly lower than hardened steel or coated components. Stable wear behavior improves repeatability in automated production environments. ADCERAX® tailors surface finish to balance wear resistance and mating compatibility.

Automotive Technical Ceramic materials tolerate rapid temperature changes without cracking due to controlled microstructure and low thermal expansion. Internal stress accumulation is reduced during heating and cooling cycles. This capability is critical in exhaust, casting, and thermal processing zones. ADCERAX® selects materials based on temperature gradients rather than peak values alone.

Ceramic components applied in automotive environments remain inert to exhaust gases, molten metals, and corrosive fluids. Unlike metals, ceramic materials do not corrode, scale, or chemically react with surrounding media. Dimensional accuracy and surface integrity are preserved over time. ADCERAX® evaluates chemical exposure during material selection to prevent premature degradation.

Automotive Engineering Ceramic materials enable stable electrochemical behavior at elevated exhaust temperatures. Consistent ion conductivity and signal output are maintained in oxygen sensors. Phase and dimensional stability directly influence sensing accuracy and response time. ADCERAX® controls sintering conditions to ensure reliable ceramic phase composition.

Automotive Structural Ceramic materials provide high stiffness-to-weight ratios compared with steel. Reduced mass benefits dynamic systems and automation tooling where inertia directly affects performance. Mechanical strength remains sufficient for load-bearing roles. ADCERAX® supports lightweight ceramic designs through geometry optimization.

Ceramic components applied in automotive environments offer superior insulation and heat resistance compared with high-performance polymers. Polymers often degrade or deform under sustained thermal and electrical stress. Ceramic alternatives maintain shape and insulation integrity throughout service life. ADCERAX® evaluates replacement scenarios based on voltage and temperature profiles.

Automotive Industrial Ceramic parts require clear definition of operating temperature range, electrical load, chemical exposure, and mechanical stress. Geometry constraints and tolerance requirements must also be specified early. Incomplete data often leads to redesign or performance gaps. ADCERAX® supports engineering review to clarify specifications before production.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.